Oscilloscopes play a crucial role in the field of automotive engineering, enabling professionals to accurately diagnose and troubleshoot complex electrical and electronic systems in vehicles. With the rapid advancement of automotive technology, the need for precise and efficient diagnostic tools has become more important than ever.

What is Automotive Oscilloscope Diagnostics?

Automotive diagnostics using an oscilloscope allows engineers to visualize and analyze electrical waveforms, helping them identify irregularities, faults, or abnormalities in various automotive systems.

Unlike traditional diagnostic tools, such as multimeters or scan tools, oscilloscopes provide engineers with a more detailed and comprehensive view of the electrical signals within a vehicle. This level of precision allows for a deeper understanding of the root cause of a problem, leading to more accurate diagnoses and efficient repairs.

Key Applications for Oscilloscopes in Automotive Diagnostics

How to Use an Automotive Oscilloscope

Service-Level / In-Vehicle Diagnostics

Step 1: Connecting the Oscilloscope

The first step in using an automotive oscilloscope is to properly connect it to the vehicle's electrical system. This ensures accurate signal measurement and analysis. Follow the steps below to connect the oscilloscope:

- Locate the Diagnostic Port

Start by locating the vehicle's diagnostic port, which is usually located under the dashboard or near the steering column. Refer to the vehicle's manual or consult an online resource for the exact location of the diagnostic port. - Connect the Probe Leads

Once you have located the diagnostic port, connect the oscilloscope's probe leads to the appropriate pins on the diagnostic port. Ensure a secure connection to avoid any signal loss or interference. The probe leads should be color-coded, with one lead connected to the ground pin and the other lead connected to the signal pin

Step 2: Setting up the Oscilloscope

After connecting the oscilloscope to the vehicle, it is important to properly set up the oscilloscope to ensure accurate signal measurement. Follow the steps below to set up the oscilloscope:

- Power on the Oscilloscope

Turn on the vehicle's ignition and power up the oscilloscope. Make sure the oscilloscope is receiving power and is ready for operation. Check the oscilloscope's display to ensure it is functioning properly. - Adjust the Voltage Range and Timebase Settings

Before capturing signals, it is important to set the correct voltage range and timebase settings on the oscilloscope. This ensures that the oscilloscope can accurately capture and display the desired signal frequency. Consult the oscilloscope's user manual for specific instructions on adjusting these settings.

Learn more about how to set up and use an oscilloscope

Device-Level Diagnostics

Reading and Interpreting Oscilloscope Patterns

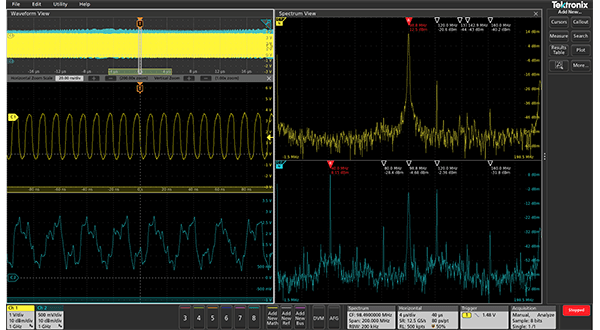

Now that the oscilloscope is properly connected, it's time to read and interpret the patterns displayed on the screen. Oscilloscope patterns provide valuable information about the electrical signals in the vehicle's system, helping you diagnose and troubleshoot issues.

Start by selecting the appropriate channel on the oscilloscope and adjusting the vertical and horizontal scales to ensure a clear and accurate representation of the signal. Look for patterns such as waveforms, pulses, and spikes.

Automotive oscilloscope waveform analysis is crucial in diagnosing specific issues. For example, a steady waveform indicates a stable and consistent signal, while irregular or distorted waveforms may indicate a faulty component or a wiring problem. Additionally, pay attention to the amplitude, frequency, and duration of the patterns. These parameters can provide insights into the health and performance of the electrical system.

Learn more about how to choose the right oscilloscope for your needs

Automotive Diagnostic Example Videos from Tektronix

The Benefits of Using an Oscilloscope

Several key benefits make oscilloscopes an indispensable tool for engineers in the automotive industry:

- Accurate Fault Detection: Oscilloscopes provide engineers with real-time visual representations of electrical waveforms, allowing them to identify even the smallest anomalies or irregularities. This level of accuracy helps in pinpointing the exact location and nature of a fault, saving time and effort in the diagnostic process.

- Time-Saving: With the ability to capture and analyze complex waveforms quickly, oscilloscopes enable engineers to diagnose problems efficiently. This time-saving aspect is crucial in today's fast-paced automotive industry, where every minute counts.

- Versatility: Automotive oscilloscopes can be used to diagnose a wide range of electrical and electronic systems in vehicles, including ignition systems, fuel injectors, sensors, actuators, and communication networks. This versatility makes them an essential tool for engineers working on various automotive platforms.

- In-Depth Analysis: Oscilloscopes provide engineers with detailed information about the shape, amplitude, frequency, and timing of electrical signals. This level of analysis allows for a deeper understanding of the behavior of automotive systems, leading to more effective troubleshooting and problem-solving.

How Automotive Oscilloscope Diagnostics Aid Engineers

Engineers in the automotive industry heavily rely on oscilloscopes for a wide range of diagnostic tasks:

- Electrical System Troubleshooting: When faced with electrical issues in a vehicle, engineers can use oscilloscopes to analyze the voltage and current waveforms, helping them identify faulty components or wiring problems.

- Sensor and Actuator Testing: Oscilloscopes allow engineers to test the performance of various sensors and actuators, such as oxygen sensors, throttle position sensors, and fuel injectors. By analyzing the waveforms generated by these components, engineers can determine their functionality and detect any abnormalities.

- Communication Network Analysis: Modern vehicles often feature complex communication networks, such as CAN (Controller Area Network) or LIN (Local Interconnect Network). Oscilloscopes enable engineers to monitor and analyze the data transmitted through these networks, helping them identify communication errors or malfunctions.

- Performance Optimization: By using oscilloscopes to analyze the performance of automotive systems, engineers can fine-tune and optimize their operation. This optimization leads to improved fuel efficiency, reduced emissions, and enhanced overall vehicle performance.

Final Thoughts

With their ability to accurately diagnose electrical and electronic problems, oscilloscopes help save time, improve efficiency, and ensure the reliability of automotive systems. By leveraging the benefits of oscilloscope diagnostics, engineers can overcome complex challenges and deliver high-quality solutions in the ever-evolving world of automotive engineering.

If you'd like to explore tools for diagnosing automotive issues, consider exploring the following: