Contact us

Call us at

Available 6:00 AM – 5:00 PM (PST) Business Days

Download

Download Manuals, Datasheets, Software and more:

Feedback

DDR test challenges in the era of 5G technology

Adoption of 5G is driving growth in a variety of exciting technologies – from augmented reality (AR) and artificial intelligence (AI) to cloud computing and IoT. All of these rely on more data being both stored and accessed more quickly, hence the importance of fifth generation memory (DDR5). DDR5 improves bandwidth, density and channel efficiency, but higher data transfer rates and faster signal speeds lead to complex designs that push the boundaries of signal integrity and require higher performance measurements for DDR compliance test, DDR debug and validation.

DDR Memory Testing Solutions

DDR5 DRAM Transmitter and Receiver

Tektronix Clarius DDR5 DRAM Compliance software provides a comprehensive transmitter and receiver solution for validating and characterizing DDR5 DRAM devices as per JEDEC specification.

Latest disaggregated architecture optimizes oscilloscope utilization and run transmitter and receiver on one unified software platform.

DDR5 System Transmitter Solution

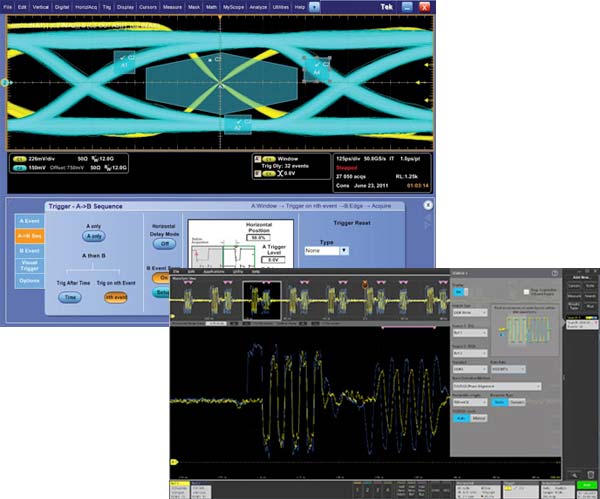

The TekExpress DDR5 System Transmitter solution conforms to the JEDEC memory standard requirements so you can spend more time validating the memory design and less time collecting the data. DDR5 test automation software option is available on MSO / DPO70000 Mixed Signal Oscilloscopes and DPO70000SX ATI Performance Oscilloscopes.

Key Features:

- DFE analysis on the bursty DDR traffic and write data eye measurements

- De-embedding with SDLA

- Supports Up to 15000M T/s data rate in user defined mode

- DDR DFE standalone application

Learn More:

LPDDR5

The TekExpress LPDDR5 Transmitter solution meets the latest JEDEC memory standard requirements so you can confidently validate LPDDR5 DRAM designs at the maximum data rates. Supported on MSO / DPO70000 Mixed Signal Oscilloscopes and DPO70000SX ATI Performance Oscilloscopes.

Key Features:

- Automated read and write burst separation

- De-embedding techniques using SDLA

- Faster times for a faster time to market

- Multiple Burst Detection Method supported - Read and Write, Write Only, Read Only, and Visual Search

- Hexagon shape mask and margin analysis for Write Data, CA, CS Eye measurement

Learn More:

LPDDR4

Fast data rates, flexibility and proven technology make LPDDR4 DRAMs extremely common in wearables, medical, automotive and IoT applications.

Tektronix Clarius LPDDR4 Automated Transmitter solution meets the latest JEDEC specification for validating and characterizing LPDDR4 designs at highest data rates. Perform conformance testing with one click.

Latest disaggregated architecture optimizes oscilloscope utilization and accelerates test times.

Clarius LPDDR4 Tx Datasheet (PC-based)

Debug designs using Tektronix DDR – LP4 solution with automated read, write burst separation and flexibility to select tests at highest data rates for targeted analysis.

DDR4, DDR3 and LPDDR3

Fast data rates, flexibility and proven technology make previous generations of DDR4, DDR3 and LPDDR3 DRAMs extremely common in wearables, medical and IoT applications.

DDR4 and DDR3/LPDDR3 test automation software is available for use with MSO / DPO70000 Mixed Signal Oscilloscopes and DPO70000SX ATI Performance Oscilloscopes. DDR3/LPDDR3 automation software is also available for use with Tektronix 6 Series B MSO Mixed Signal Oscilloscopes.

Key Features:

- Easy identification of reads and writes

- Automated setup and testing per JEDEC specifications

- Automated report generation

- Support for a wide range of interposers and high-performance probes

Learn More:

DDR/LPDDR Gens 3 and 4 Testing on MSO/DPO70000 and DPO70000SX Oscilloscopes

Frequently Asked Questions (FAQ)

What is DDR memory test?

DDR (Double Data Rate) memory test refers to the process of evaluating the performance, functionality, and reliability of DDR memory modules, such as DDR4 or DDR5, used in computer systems. DDR memory test is conducted to ensure that these memory modules operate as intended and meet specific quality and compatibility standards. Here's a more detailed explanation of DDR memory testing:

-

Performance Verification: DDR memory modules are tested to verify their performance characteristics, such as data transfer rates, latency, and bandwidth. These tests ensure that the memory meets the specified speed and efficiency requirements.

-

Timing and Signal Integrity: DDR memory testing includes timing tests to confirm that data is read from and written to the memory at the correct timings. Signal integrity tests check for any signal distortions or noise that might affect data integrity during communication.

-

Data Integrity: DDR memory test also checks for data integrity and error correction capabilities. It verifies that data stored and retrieved from the memory is accurate and reliable.

-

Stress Testing: Stress tests subject the memory modules to extreme conditions, such as high temperatures or voltage fluctuations, to assess their resilience and reliability under adverse circumstances.

-

Compatibility Testing: DDR memory modules need to work seamlessly with various motherboards and chipsets. Compatibility testing ensures that the memory is compatible with a wide range of hardware configurations.

-

Power Consumption Analysis: DDR memory testing includes assessments of power consumption to ensure that the memory modules meet energy efficiency standards and don't consume excessive power.

-

Compliance with Standards: DDR memory testing follows industry standards and specifications set by organizations like JEDEC (Joint Electron Device Engineering Council). Compliance with these standards is essential for product certification and market acceptance.

-

Quality Assurance: DDR memory testing is a critical part of the quality control process in manufacturing. It helps identify and address issues early in the production cycle, reducing the likelihood of faulty memory modules reaching consumers.

-

Product Validation: Manufacturers and developers use DDR memory testing to validate the performance of memory modules in real-world applications, ensuring they meet the demands of modern computing tasks.

Why is DDR test important?

DDR test is crucial to ensure that memory modules function correctly, as memory-related issues can lead to system instability, crashes, or data corruption. It also confirms that memory modules meet their specifications, adhere to industry standards, and function correctly under various environmental conditions.

When should DDR testing be conducted?

DDR testing should be performed during the product development phase to identify and rectify any issues early in the design process. It's also done as part of quality control in manufacturing.

What are DDR4 and DDR5 tests?

DDR4 and DDR5 tests are specific tests designed for DDR4 and DDR5 memory modules, respectively. These tests ensure that these memory modules meet the respective DDR4 or DDR5 specifications.

What are DDR test tools and equipment necessary for testing?

To comprehensively test DDR (Double Data Rate) memory, a suite of essential tools and equipment is required, such as:

-

Memory testers for functional and performance assessments

-

Oscilloscopes, interposers/fixtures, current and voltage probes to measure electrical timing and voltage parameters to analyze signal integrity.

-

Bit error rate testers (BERT) to check the receiver specifications.

-

Load boards for realistic simulations

-

Environmental chambers for temperature and humidity testing

Additionally, Clock generators are also used for synchronization. High-quality cables, connectors, safety equipment, and computer workstations round out the essential equipment for accurate and reliable DDR memory testing.