Contact us

Call us at

Available 6:00 AM – 5:00 PM (PST) Business Days

Download

Download Manuals, Datasheets, Software and more:

Feedback

Develop more reliable products faster!

To get a reliable product to market in the shortest period of time, you need a process that quickly stresses the product and points out any possible design and manufacturing weaknesses.

With our experienced technical staff and on-site test equipment from leading industry suppliers, we can help you with all your testing requirements. For more than 70 years, Fortune 500 companies in the military, aerospace, telecom, medical and semiconductor industries have relied upon Tektronix to satisfy their component-through-product level test requirements.

HALT Testing: Elevating Product Reliability through Rigorous Evaluation

What is HALT Testing

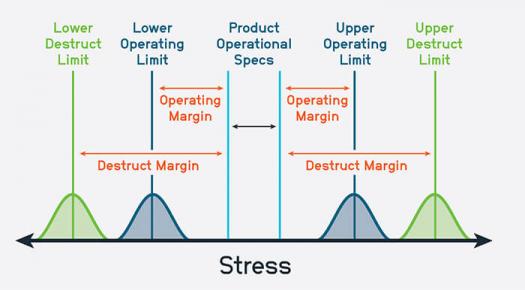

Highly Accelerated Life Testing (HALT) is a formidable method meticulously crafted to unearth design flaws and vulnerabilities concealed within electronic and mechanical assemblies. By subjecting products to conditions of unparalleled extremity, well beyond customary operational parameters, HALT Testing strategically exposes issues that may otherwise lie dormant until deployment in real-world scenarios.

Stress Testing: Exploring & Evaluating Material and Design Thresholds

HALT Testing subjects your product to extreme conditions that significantly exceed typical usage parameters. This encompasses:

-

Temperature Variations: Exposing the product to severe temperature fluctuations.

-

Rapid Thermal Cycling: Imposing rapid and repetitive temperature transitions to unearth latent weaknesses.

-

Multi-Axis Vibration: Vigorous, multi-axis vibration assessments designed to unmask potential vulnerabilities.

Understanding the HALT Testing Process

Streamlined HALT Testing Process

-

Plan and Stressor Selection: Begin by defining your testing objectives and identifying critical components within your product. Next, select the environmental stress factors, such as extreme temperatures and vibrations, that will be used during testing. This step sets the foundation for the entire HALT Testing process, ensuring that you have a clear direction for uncovering weaknesses.

-

Equipment Setup and Baseline Test: Properly prepare your testing equipment, ensuring it is calibrated and ready to create the desired stress conditions. Install sensors and data collection tools to monitor the product's performance. Before applying stressors, conduct a baseline test to evaluate how the product functions under normal conditions. This initial assessment provides a benchmark for future comparisons.

-

Stress Application and Monitoring: Gradually introduce the chosen stress factors, starting at lower levels and progressively increasing them over time. Continuously monitor the product's behavior, performance, and any deviations from expected norms. This step is crucial for observing how the product responds to stress and identifying potential issues as they arise.

-

Failure Analysis and Immediate Actions: When failures occur during HALT Testing, conduct a thorough analysis to pinpoint their root causes. If necessary, apply quick fixes to address critical issues that may disrupt the testing process or pose risks to the product's safety. Adjust stress levels and parameters as needed to maintain a controlled testing environment while addressing identified problems.

-

Iterative Testing and Data Analysis: The HALT Testing process is iterative, involving multiple cycles of stress application, monitoring, and analysis. These cycles help you identify weaknesses and operational limits systematically. Analyze the collected data to uncover trends and patterns, enabling you to prioritize and address the most critical issues that impact product reliability.

-

Documentation and Reporting: Throughout the testing process, maintain detailed documentation of findings, including failure modes, root causes, and recommended actions. Prepare comprehensive reports summarizing the results and share them with relevant stakeholders. Effective documentation ensures that insights gained from HALT Testing are communicated effectively and guide future actions.

-

Improvement and Verification: Armed with insights from HALT Testing, implement design and manufacturing changes to enhance the product's overall reliability and robustness. Conduct final verification testing to confirm that these improvements have effectively addressed identified weaknesses. Once satisfied with the product's performance and reliability, certify it for market entry, knowing that it has undergone rigorous testing and enhancements.

Why is HALT Testing Important?

HALT Testing serves as a proactive initiative for the systematic identification of latent imperfections within your product's architecture. These imperfections have the potential to manifest as operational deficiencies during real-world usage.

The primary objective of HALT Testing is to enhance the inherent reliability of your product, a critical consideration when you require:

-

Identifying Design Weaknesses: HALT Testing expedites the detection of intricate design vulnerabilities and manufacturing irregularities.

-

Thorough Failure Analysis: Failures observed during HALT Testing undergo a meticulous analysis to precisely identify their origins and root causes.

-

Strategic Deployment of Corrective Measures: Informed decisions about design and manufacturing enhancements are made, leveraging insights gained from HALT Testing. This, in turn, fortifies the overall product architecture.

-

Optimizing the Development Process: HALT Testing provides an efficient pathway to product development by swiftly addressing potential issues during both the design and manufacturing phases.

-

Accelerating Failures to Deepen Insight: The paramount goal of HALT Testing is to intentionally induce failures, acquiring invaluable insights into potential challenges and weaknesses.

-

Building Confidence for Market Entry: The culmination of HALT Testing bestows a priceless asset upon your organization: the assurance that your rigorously tested product is poised for a dependable market introduction. This assurance is pivotal in cultivating customer trust and satisfaction.

HASS Testing

Highly accelerated stress screening, or HASS testing, is a screening tool used to maintain product robustness and to identify weaknesses in manufacturing. From HALT testing we are able to extrapolate data that allows us to subject your product to a HASS that is more aggressive than conventional ESS (Environmental Stress Screen) levels.

Since HASS levels are more aggressive than conventional screening tools, a POS (proof-of-screen) procedure is used to establish the HASS effectiveness in exciting your test article to find manufacturing weaknesses, but not so high as to remove significant life from the test item. Instituting HASS to screen your product is an excellent tool to maintain a high level of robustness and it will reduce the test time required to screen a product, thus resulting in long-term savings.

The combined advantages of HASS/HALT testing are enormous: Not only do you lower product-development costs and speed up time-to-market; you can slash warranty costs — all the while improving customer satisfaction! Tektronix's experienced HALT testing engineers can assist you with all your HASS/HALT testing requirements.

With our experienced technical staff and on-site test equipment from leading industry suppliers, we can help you with all your testing requirements. For more than 70 years, Fortune 500 companies in the military, aerospace, telecom, medical and semiconductor industries have relied upon Tektronix to satisfy their component-through-product level test requirements.

Featured Content

Tektronix testing services labs are ISTA certified to perform a variety of tests.

Tektronix is certified by A2LA as an ISO/IEC 17025 Accredited laboratory. View Certificate...