Introduction

Rechargeable, or secondary, batteries are commonly used in place of disposable batteries in electronic devices such as laptops, video game controllers, mobile phones, digital cameras, and remote controls. In an effort to improve upon or replace existing battery technologies, researchers are studying ways to increase battery life and, at the same time, decrease the cost of rechargeable batteries. Common types of rechargeable batteries include Li-ion (Lithium Ion), Ni-MH (Nickel Metal Hydride), and NiCd (Nickel Cadmium). The characteristics of a rechargeable battery are commonly tested using discharge and charge cycling. Cycle tests provide information about the battery such as its internal chemistry, capacity, number of usable cycles, and lifetime. In production testing, a discharge/charge cycle is often performed to verify battery specifications and to ensure it is not defective.

A typical battery discharge/charge test configuration often includes a programmable power supply, an electronic load, an electronic switch, a voltmeter, and an ammeter. These systems require extensive software and hardware configurations to synchronize all the instruments into a working test station.

Another option is to use a potentiostat or galvanostat, which are popular instruments used for electrochemical studies. A potentiostat is an electronic instrument designed to control the voltage difference between two electrodes, typically a working electrode and a counter electrode. A galvanostat is a control and measuring device that has the ability to keep the current through an electrochemical cell constant. Controlling the current through a cell, like a rechargeable battery, is easier than controlling the potential at an electrode.

Unfortunately, there are disadvantages to using a potentiostat or a galvanostat. Many of these instruments don't have a display or many control knobs but come with designated software to run specific tests on a user-supplied PC. Users typically don't have control if they want to change a test or re-use the equipment for an application not specified in the list of predefined tests. Without access to the source code or the programming commands, users are unable to perform customized tests, or to reuse the equipment for other applications (such as basic I-V curves) in the lab.

Many potentiostats or galvanostats may also have limited current and voltage source output capacity. Galvanostats are often limited to hundreds of milliamps or less in sink (discharge) or source (charge) mode. High current options may not be able to sink current.

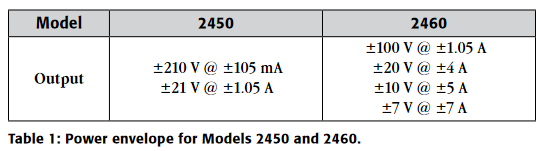

Battery testing can be simplified by using an instrument called a Source Measure Unit (SMU) or SourceMeter® instrument.A SourceMeter is a type of test instrument that is capable of sourcing and measuring both current and voltage. Keithley's Model 2450 and Model 2460 SourceMeter SMU Instruments have the flexibility to source/sink current as well as measure voltage and current, making them perfect solutions for galvanic cycling of batteries. By using the Model 2450 or Model 2460, the user only needs to set up a single unit instead of an entire rack full of equipment. As a result, the Model 2450 or Model 2460 can charge up the battery by sourcing current, discharge the battery by dissipating power, and monitor the battery's voltage and load current.

Battery Charging/Discharging

Rates for constant current charging and discharging are defined in terms of the battery’s capacity, which is the amount of electrical charge that the battery can store. The capacity is specified in milliamperehours (mAh) available and should be expressed in terms of a discharge, or load, current. The rate at which the discharge current will discharge the entire battery in one hour is known as the C-rate.For example, a battery rated at 1000mAh will output 1000mA for one hour if discharged at 1C.If a 500mAh cell is discharged at 50mA, then it is discharged at one-tenth the C-rate (0.1C) and therefore can source 50mA for ten hours.

Test Description

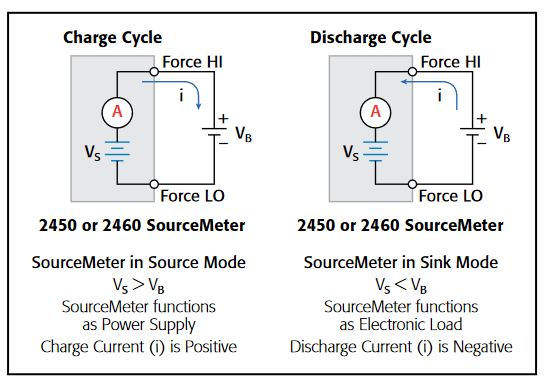

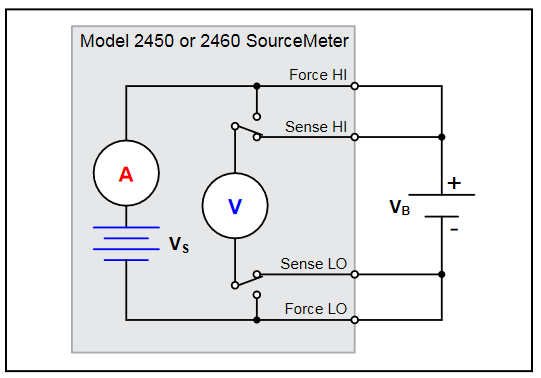

For both the charging and discharging cycles, the Model 2450 or Model 2460 SourceMeter SMU Instrument is configured to source voltage and measure current. A simplified circuit diagram of both the charge and discharge cycles is shown in Figure 2.

A battery is usually charged using a constant current. This is accomplished using the SourceMeter as a voltage source set to the voltage rating of the battery with the desired charging current set as the current limit. At the start of the test, the battery voltage is less than the voltage output setting of the SourceMeter. As a result, this voltage difference drives a current that is immediately limited to the user-defined current limit.When in current limit, the SourceMeter is acting as a constant current source until it reaches the programmed voltage level. As the battery becomes fully charged, the current will decrease until it reaches zero or near zero. To prevent safety hazards or damage to the battery, care must be taken not to overcharge the battery.

When discharging a battery, the SourceMeter operates as a sink because it is dissipating power rather than sourcing it. The voltage source of the SourceMeter is set to a lower level than the battery voltage. The current limit sets the discharge rate. When the output is enabled, the current from the battery flows into the HI terminal of the SourceMeter. As a result, the current readings will be negative. The discharge current should stay constant until the battery voltage decreases to the voltage source setting of the SourceMeter.

Making Connections to the Battery

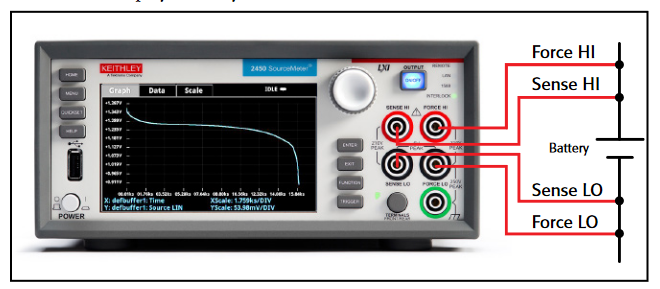

To set up the test, the Model 2450 or Model 2460 SourceMeter SMU Instrument is connected to the battery as shown in Figure 3. A four-wire, or remote sense, connection is made from the instrument terminals to the battery to eliminate the effects of the lead resistance. This enables the battery voltage to be measured as close as possible to its terminals.

The Force HI and Sense HI output terminals of the SourceMeter are connected to the positive (+) terminal of the battery and the Sense LO and Force LO outputs are connected to the negative (–) terminal of the battery.

When the output of the SourceMeter SMU Instrument is turned off, be sure that it is set to the High Impedance (High Z) Output Off State. With High Z Output Off State selected, the output relay opens when the output is turned off. This will prevent the battery from draining while the output is off. To set the Output Off State to High Z, press the MENU key and select Source Settings. Select High Impedance and then press HOME.

Automating the Discharge Cycle

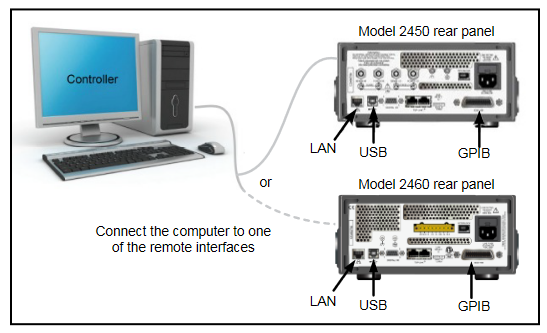

Charging and discharging cycles often take several hours, so automating the test is important. The tests can be executed using any of the supported communication interfaces for the instrument (GPIB, USB, or Ethernet). The rear panel connection locations for the remote communication interfaces are shown in Figure 4.

For charging and discharging, the SourceMeter should be programmed to perform the following steps:

- Set the measurement to a four-wire configuration.

- Set the SourceMeter to measure current. This will enable you to monitor the load current.

- Use the High Impedance Output Off State. This output off state opens the output relay when the Output is turned off. This will prevent the battery from draining when the battery is connected with the Output off.

- Set the SourceMeter to output voltage. Even though the unit is set to output voltage, it will be operating in constant current mode because it will be in current limit until it reaches the desired voltage.For charging the battery, VS > VB. For discharging the battery, VS < VB.

- Turn on the voltage source readback function. This will enable the SourceMeter voltmeter to measure the battery voltage as it is either charging or discharging.

- Set the current limit (or compliance) to the current level at which the battery is to be charged or discharged.This is the load current of the test.

- Read back the load current, source readback voltage, and the relative time stamp.

- Monitor the voltage until the battery voltage reaches the desired voltage level and stop the test.

Using the Model 2460 SourceMeter SMU Instrument to Discharge a 2500mAh D Cell Battery

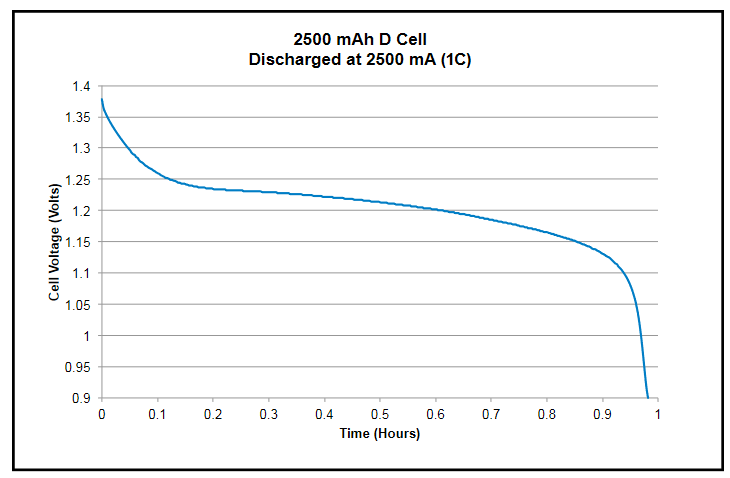

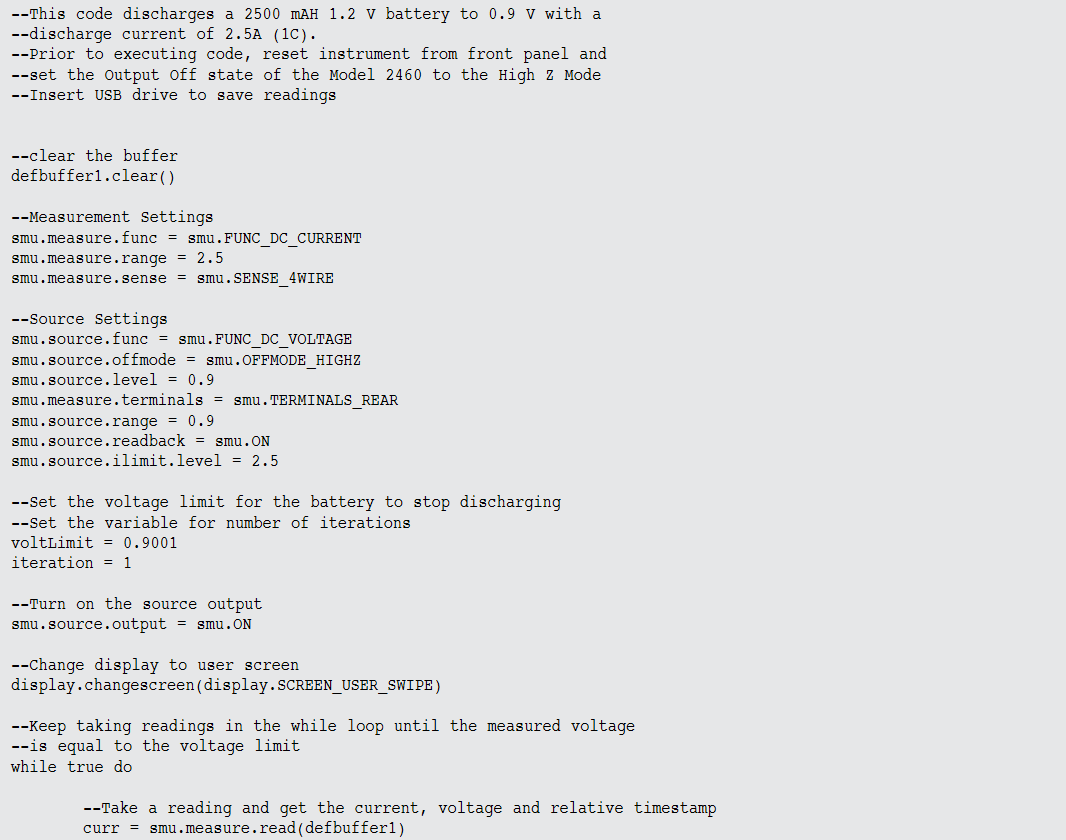

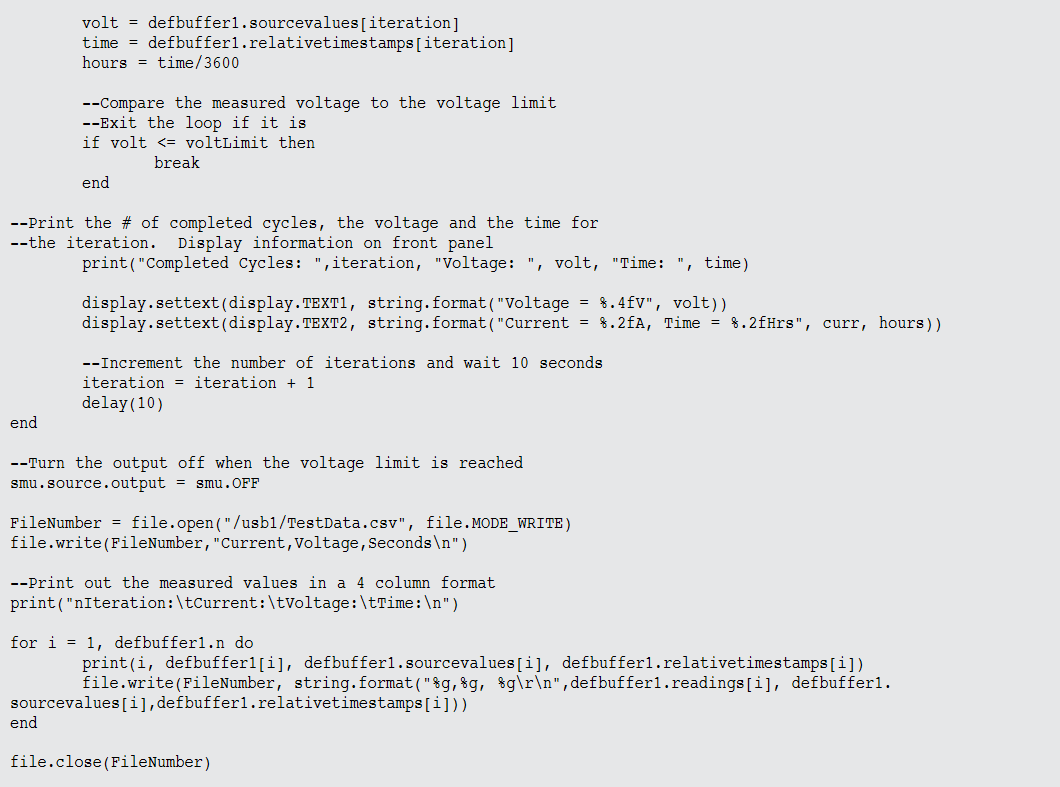

A 2500mAh D cell (1.2V) battery was used to illustrate how to discharge a battery by using the Model 2460 SourceMeter SMU Instrument. The instrument was programmed as described in the steps listed in the previous section (four-wire, source voltage, measure current, etc.) For this particular test, a 2500mAh D cell battery was discharged at a rate of 1C by using a 2.5A load current. Readings of the battery voltage, load current, and relative time were taken every ten seconds until the battery voltage reached the specified level, 1V. The results of measuring the discharge characteristics of the 2500mAh battery are shown in the graph of Figure 5.

This TSP code also saves all the current, voltage, and time readings to a USB drive connected to the front panel USB port of the Model 2460. The code can be easily modified for a specific discharge current and voltage, and can be used with either the Model 2450 or 2460, depending upon the specific current and voltage levels.

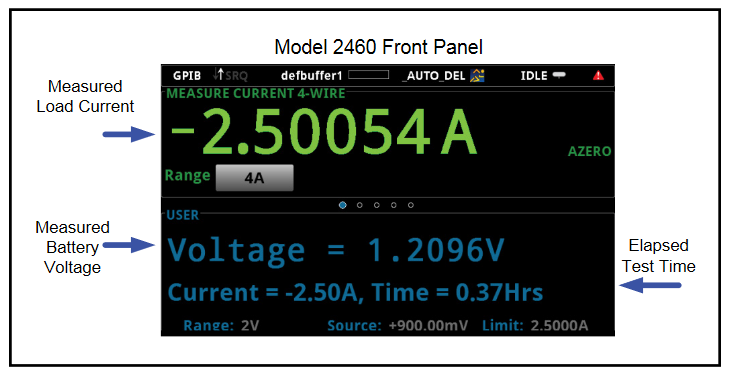

In addition to monitoring the readings over the bus, the SourceMeter can simultaneously display on its user interface the load current, the battery voltage, and the elapsed test time while the test is in progress. Notice the large, easy-to-read measurements of the D cell battery on the Model 2460 display that is shown in the screen capture in Figure 6.

The code used to generate the discharge characteristics is listed in the Appendix. Although the SourceMeter's flexibility lets the user choose either SCPI or TSP® (Test Script Processor) commands for programming, this code was written with TSP commands using the software tool, Test Script Builder. This is a free software tool that is provided with the Model 2450/2460 to help users create and modify TSP code and scripts. It also has an immediate instrument control console to send commands and receive data from the instrument.

Before executing this code and connecting the battery to the output terminals of the Model 2460, reset the instrument and then set the Output Off State from Normal to the High Impedance. The unit can be reset by pressing MENU -> Manage -> System Reset -> OK. Next, change the Output Off State by selecting MENU and then pressing the Normal Output Off State button. Select High Impedance. This output off state opens the output relay when the Output is turned off, preventing the battery from draining.

To execute this code, the Model 2460 must be in the TSP command set mode (SCPI command is the default). To change to the TSP command set, press MENU and then Settings. Press the Command Set button and select TSP. Also make sure you are using the latest version of Test Script Builder, which can be downloaded for free from the Keithley website.

Conclusion

The Model 2450 or Model 2460 SourceMeter SMU Instrument is an ideal tool to perform charge and discharge cycle testing on rechargeable batteries because of its accurate four-quadrant, high power output and the ability to measure both current and voltage accurately. Using a single instrument to perform battery testing simplifies test setup, reduces programming time, and saves rack space.

NOTE: Please refer to the Model 2450 or 2460 User's Manual for safe operating instructions when charging and discharging batteries.

Appendix: TSP code used to generate discharge characteristics of the 2500mAh battery

Find more valuable resources at TEK.COM

Copyright © Tektronix. All rights reserved. Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all previously published material. Specification and price change privileges reserved. TEKTRONIX and TEK are registered trademarks of Tektronix, Inc. All other trade names referenced are the service marks, trademarks or registered trademarks of their respective companies.

No.3221 10.20.14