Battery Emulation Testing for Repeatable and Efficient Results

How can we test battery-powered electronics? If we test with a battery or a battery pack, we are working with a voltage source that does not have a constant output. The battery output is not repeatable and must be disposed of if it is a primary battery or re-charged if it is a secondary battery.

We could use a conventional power supply, but we cannot ensure that the electronics perform correctly, particularly near a battery’s low voltage threshold. A superior solution is a battery emulator, a power supply that can emulate the characteristics of a battery. The battery emulator enables testing under controlled, repeatable conditions, which are difficult to reproduce with a battery. Battery output varies as a function of both the number of times it has been cycled and its internal temperature. Testing can be faster with a battery emulator since, unlike a battery, the battery-emulating power supply can quickly change its output. The battery emulator is most important for testing electronics under realistic conditions.

EA bidirectional power supplies offer battery emulator testing solutions.

So, what is a battery emulator?

A battery emulator is a power supply with special characteristics. It simulates the internal resistance of a battery, allowing the battery emulator to output a voltage that is equivalent to the battery’s voltage when powering a load. In addition, the power supply must be bidirectional to source and sink power to emulate a rechargeable battery’s charge cycle. Acting as a load enables testing a device’s battery charging circuitry. To test a charger’s protection logic, the bidirectional power supply can safely simulate overcharge and undercharge conditions.

How does the battery emulator work?

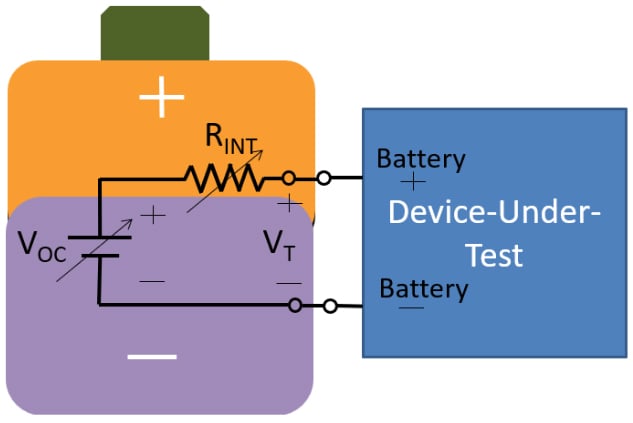

We can describe it, with a simplified model, as a variable voltage source with a variable internal resistance, as shown in Figure 1. The variable voltage source enables a voltage output representing an individual cell or a battery pack. The voltage output can be a few volts for a battery cell or up to 800 V for an electric vehicle (EV) battery pack. Resistance levels can reflect the resistance of the various battery chemistries.

The battery emulator output to a load is the voltage at its terminals, VT = VOC – ILoad·RINT. Since the internal resistance increases as a battery discharges, the battery emulator can adjust the internal resistance to allow testing at various states of the battery. It is important to test at low voltage so designers can ensure that their circuit design does not shut down prematurely, which reduces operational life between charges and battery replacement. Also, shutdown can be too late, indicating an unexpected failure.

Figure 1. Model of a battery as a variable DC source, the open circuit voltage, VOC, with a variable internal resistance, RINT.

EA Elektro-Automatik (EA) offers a family of programmable DC bidirectional power supplies that can be a battery emulator for an individual cell, a module, or an EV battery. The family consists of more than 60 DC bidirectional power supplies with power levels from 600 W to 60 kW. Models include voltages up to 2000 V or current capacity up to 1000 A. These power supplies are housed in full rack enclosures with heights up to a compact 6U for the 60 kW devices. Systems can paralleled together for up to 3.84 MW.

These power supplies simulate an internal resistance by monitoring the load current and reducing their output by the product of the load current and the programmed internal resistance. As bidirectional power supplies, they can sink charger current and absorb up to 60 kW. EA power supplies are regenerative and can return up to a market-leading 96.5% of the absorbed energy to the power grid. Thus, they are highly cost-effective. These regenerative power supplies improve reliability by reducing the heat load on the supply. Of greater significance is the annual utility cost savings these devices yield.

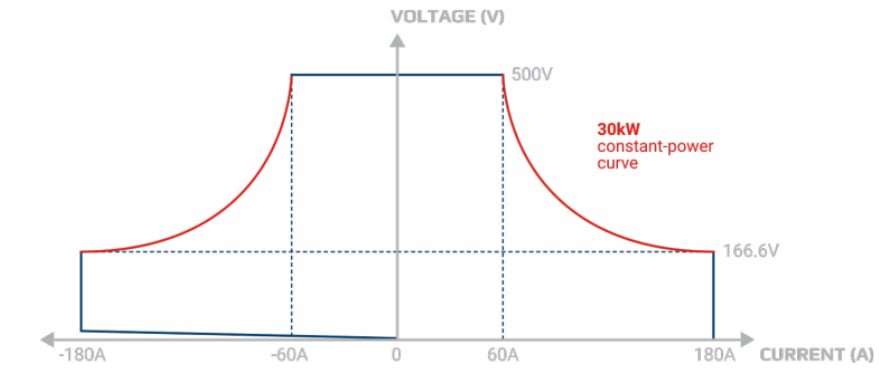

A key advantage of the EA bidirectional power supplies is their true autoranging capability. As shown in Figure 2, an EA autoranging supply has a characteristic output that offers a wide current output (or input) range. They deliver (or absorb) full power down to 1/3 of their rated voltage, enabling simulation of a battery delivering full power to its load (or absorbing full power from a charger). To be capable of supplying the same current as a true autoranging EA power supply, a conventional power supply with a rectangular output characteristic would have to have three times more power. In the case of the 30 kW autoranging power supply shown in Figure 2, the conventional power supply would have to be a 90kW supply. That is a huge, high-cost supply. Thus, EA power supplies offer substantial cost and space savings over a conventional power supply with equivalent voltage and current ratings.

Figure 2. Autoranging output (and input) characteristic of an EA 10000 series bidirectional power supply

Software to complete the battery simulation testing

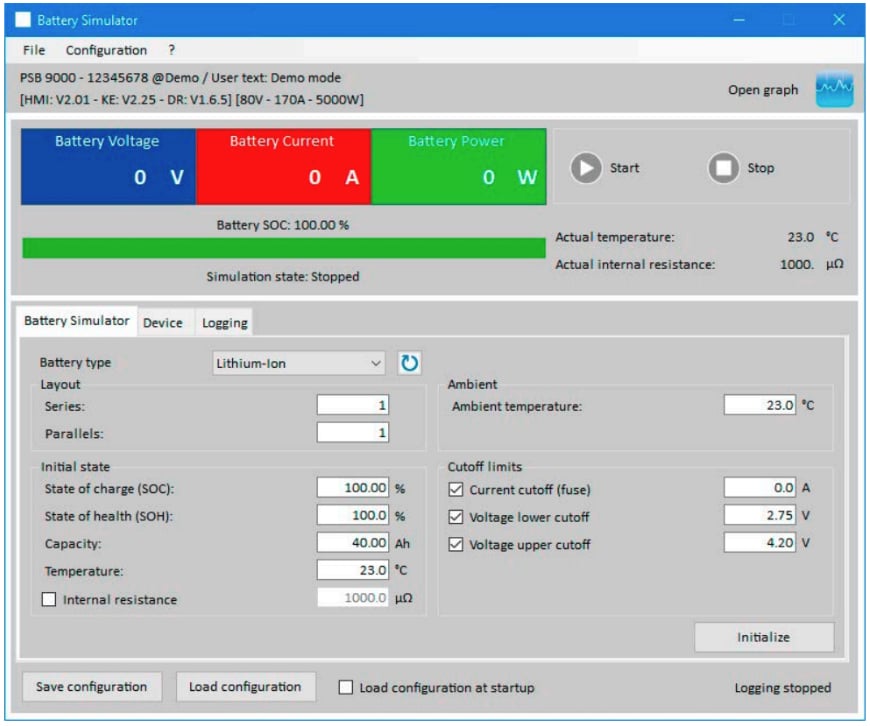

EA Battery Simulator software combined with 10000 series bidirectional power supplies enables battery simulation of lead-acid and lithium-ion battery charging and discharging characteristics. The software does not require any coding. Just enter test parameters into the graphical user interface shown in Figure 3. Test parameters for simulating a battery state include internal resistance, battery temperature, ambient temperature, State-of-Charge (SOC) and State-of-Health (SOH). These parameters fully characterize the state of the battery.

The Battery Simulator software allows the simulation of battery packs with combinations of series and parallel cells, an essential feature for testing high-power batteries such as EV batteries. While executing charge and discharge cycles, the software displays the battery response in real-time. EA Battery Simulator software and bidirectional power supplies ensure automated, repeatable, cost-efficient testing.

Figure 3. EA Battery Simulator software main window for parameter entry

Maximize the quality of your battery emulation testing

The use of battery-emulating power supplies allows higher quality, repeatable, and realistic testing of battery-operated electronics and charging circuitry. The more realistically a battery-operated product or a battery charger can be tested, the better the chance it will perform to specifications.

For assistance with a battery emulation testing requirement, check out the EA-PSB 10000 series Programmable DC Bidirectional Power Supplies at Bidirectional DC Power Supply and the high-power 30 kW and 60 kW PUB Industrial Series Bidirectional Power Units at EA-10000 Industrial Series. Complete your system with the EA Battery simulation software described at EA Battery Simulator and Simulation Software. Explore how about EA Elektro-Automatik technology can support you with your work.