Contact us

Call us at

Available 6:00 AM – 5:00 PM (PST) Business Days

Download

Download Manuals, Datasheets, Software and more:

Feedback

Benchtop Digital Multimeter (DMM)

Choose the best benchtop digital multimeter (DMM) for your application

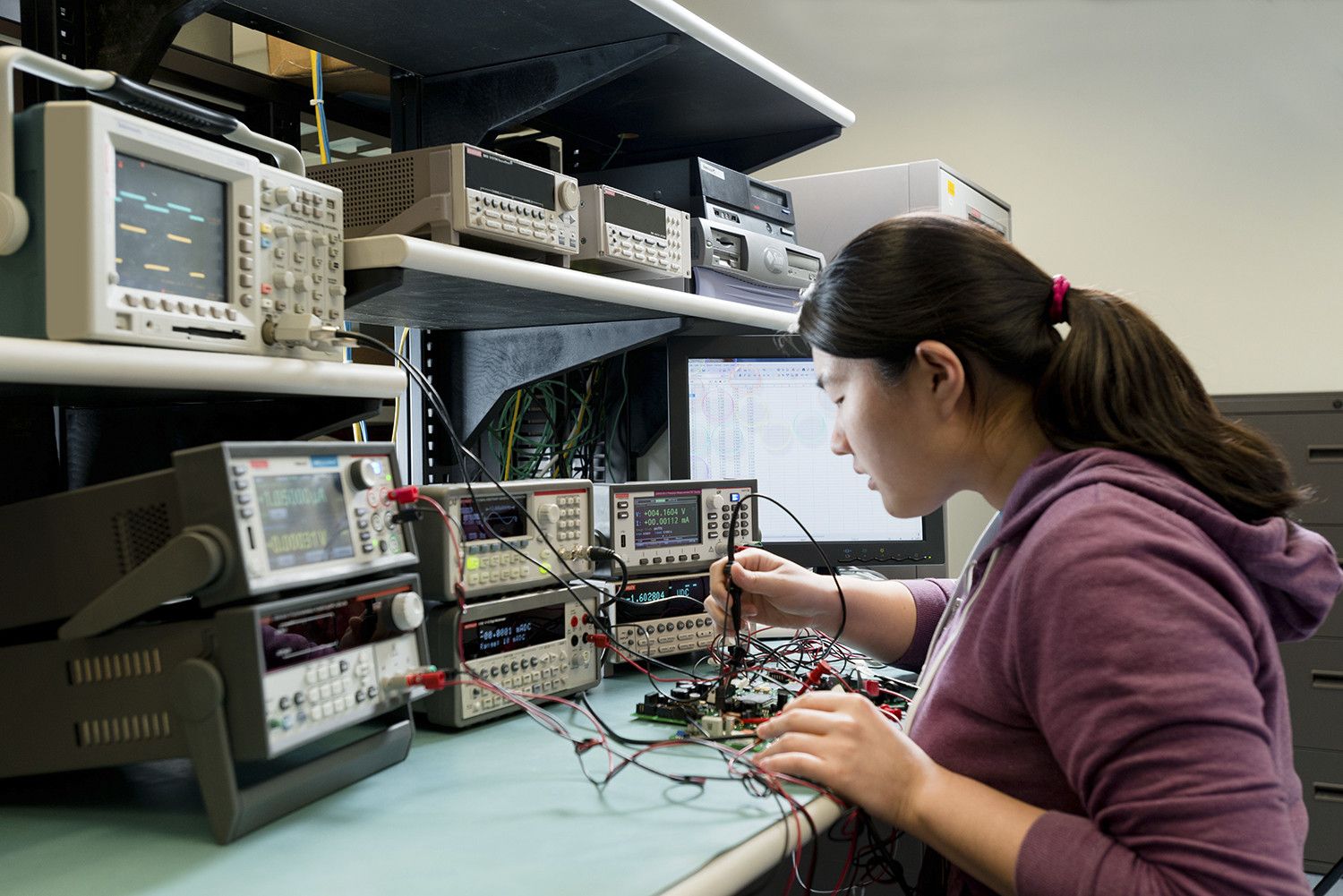

Keithley offers the widest range of system and benchtop digital multimeters to meet any measurement requirement. This line of digital multimeters (DMMs) addresses the requirements for student labs with basic DMMs and fast and accurate DMMs for component, module, and assembled product manufacturing testing.

Which digital multimeter is right for you?

Precision Series

The Precision Series are high-end digital multimeters, notable for their touch screen interface that streamlines the transition from data collection to analysis. This series combines high accuracy with speed, exemplified by the DMM7510 model, which stands out as one of the most accurate 7.5-digit DMMs on the market. Ideal for tasks requiring precise and rapid measurements, it's a top choice for advanced scientific and engineering applications.

Specialty Series

The Specialty Series of digital multimeters is designed for exceptional performance and optimization for your specific task. Models in this series are adept at highly accurate measurements, including AC voltage with extended bandwidth for control system analysis and ultra-precise measurements up to 8.5 digits. This series is ideal for advanced electronics testing, precision manufacturing, and scientific research where detailed accuracy is paramount. These multimeters offer specialized functionalities tailored to niche measurement needs.

Instrumentation Series

The Instrumentation Series of digital multimeters focuses on providing the fundamentals of test and measurement with trustworthy results. These multimeters are reliable and easy to use, making them perfect for standard day-to-day measurement tasks. They offer a solid balance between performance and affordability, suitable for educational purposes, general electronic troubleshooting, and basic industrial applications.

If multi-channel measurements greater than ten channels are needed, see our Switching and Data Acquisition Systems.

Also consider Keithley Source Measure Unit (SMU) instruments, with integrated digital multimeter, power supply, current source, and electronic load capabilities.

Benefits of Keithley digital multimeters (DMM)

Get the following performance benefits of a benchtop digital multimeter from Keithley:

- 5½-digit resolution to 8½-digit resolution DMMs

- 6ppm basic voltage measurement accuracy on the 8½-digit DMM for calibration laboratories

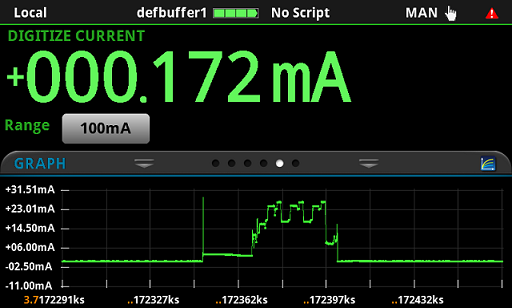

- Fast, 1 Msample/s sampling speed to capture complex, low level current profiles from IoT devices or other wireless devices

- Sensitivity of 1 µΩ and 1 pA to test low power devices for research, design, and manufacturing test

- A wide range of measurement functions such as DC and AC volts, DC and AC current, two- and four-wire Ohms, continuity, frequency, period, RTD, thermistor, and thermocouple temperatures, diode test, and capacitance

- Numerous interface options including LAN/LXI, USB-TMC, GPIB, and RS-232 for data acquisition and automated testing

- Intelligence to execute tests and create customized measurements with minimal PC interaction

- Measurement expansion up to ten channels

Unveiling the Digital Multimeters: A Comprehensive Guide

Digital multimeter, affectionately known as the DMM, is an indispensable tool for anyone working in the realm of electronics. It serves as a versatile measuring instrument, capable of quantifying a variety of electrical parameters, including voltage, current, and resistance. Whether you're a seasoned professional or a budding enthusiast, understanding the intricacies of the DMM is crucial for navigating the world of electronics with precision and confidence.

What is a Digital Multimeter?

A benchtop digital multimeter measures electrical stimuli, including voltage, current, and resistance. It’s a diagnostic tool used by electrical and electronic engineers daily and combines the features of a voltmeter, ammeter, and ohmmeter.

What is a Digital Multimeter Used For?

Here are some common applications of the DMM:

-

Troubleshooting: DMMs are instrumental in identifying and resolving electrical faults in circuits, components, and devices.

-

Component Testing: DMMs can measure the electrical characteristics of individual components, ensuring they meet the required specifications.

-

Circuit Testing: DMMs are used to verify the proper operation of electronic circuits, ensuring they deliver the expected voltages and currents.

-

Battery Testing: DMMs can measure the voltage and current output of batteries, assessing their health and performance.

How to Choose the Right Digital Multimeters

With a plethora of DMMs available in the market, selecting the most suitable one for your needs can be daunting. To make an informed decision, consider the following factors:

-

Measurement Accuracy: The accuracy of a DMM is paramount, especially for applications where precise measurements are critical. Look for DMMs with high accuracy specifications, indicated by a lower percentage uncertainty value.

-

Measurement Range: The measurement range determines the range of values the DMM can measure. Ensure the DMM's range encompasses the values you'll typically encounter in your applications.

-

Features and Functions: DMMs offer a variety of features and functions, such as data logging, true RMS measurements, and relative mode. Choose a DMM with features that align with your specific requirements.

-

Safety Ratings: Safety is paramount when working with electrical equipment. Ensure the DMM you choose meets the safety standards for the intended applications.

For more specific details on criteria and specifications for choosing a DMM, please refer to our Digital Multimeters Selector Guide.

Resources

Digital multimeter FAQs

How do digital multimeters work?

Digital multimeters attach to probes, leads, or clamps, which are connected to an electronic device. They then measure the device's voltage, current, or resistance and use an analog to digital converter to present a value on the display.

How do you use a benchtop multimeter?

Here's a step-by-step guide on how to use a digital multimeter:

1. Familiarize Yourself with the Multimeter: Before starting, take some time to familiarize yourself with the different parts of the multimeter, including the display, function selector knob, range selector knob, test leads, COM (common) terminal, and measuring terminal.

2. Choose the Measurement Type: Decide on the type of measurement you want to perform, such as voltage, current, or resistance. This will guide you in setting the function selector knob to the appropriate position (V, A, or Ω).

3. Select the Measurement Range: Estimate the approximate value of the parameter you're measuring. Set the range selector knob to a range that encompasses this value. Start with a higher range and gradually decrease it until you get a stable reading on the display.

4. Connect the Test Leads: Connect the black test lead to the COM terminal on the multimeter. Connect the red test lead to the appropriate measuring terminal based on the measurement type:

- Voltage: Red lead to the positive terminal of the circuit or component.

- Current: Red lead in series with the circuit element where you want to measure the current.

- Resistance: Red lead to one terminal of the resistor, black lead to the other terminal.

5. Turn on the Multimeter: Press the power button to turn on the multimeter.

6. Touch the Probe Tips: Carefully touch the probe tips of the test leads to the appropriate points on the circuit or component being measured. Ensure proper contact and avoid touching any other conductors or yourself.

7. Observe the Reading: Observe the displayed reading on the multimeter. The value will indicate the measurement of the parameter you selected.

8. Interpret the Reading: Pay attention to the units displayed along with the reading (V, A, or Ω). For voltage measurements, consider the polarity: positive for red lead on positive terminal, negative for red lead on negative terminal.

9. Disconnect the Test Leads: Once the measurement is complete, remove the test leads from the circuit or component.

How to read a digital multimeter?

Reading a digital multimeter involves understanding the different parts of the meter and how they work together to provide electrical measurements. Here's a step-by-step guide on how to read a digital multimeter:

1. Identify the Components:

A digital multimeter typically consists of the following components:

-

Display: The screen where the measurement readings are displayed.

-

Function Selector Knob: A dial or switch used to select the type of measurement you want to make, such as voltage, current, or resistance.

-

Range Selector Knob: A dial or switch used to select the range of values the meter can measure.

-

Test Leads: Two wires with probes at the ends, used to connect the meter to the circuit or component being measured.

-

Common Terminal (COM): The black test lead is typically connected to this terminal, which serves as the reference point for the measurements.

-

Measuring Terminal: The red test lead is typically connected to this terminal, which is used to make the actual measurement.

2. Connect the Test Leads:

-

Connect the black test lead to the COM terminal on the multimeter.

-

Connect the red test lead to the appropriate measuring terminal, depending on the type of measurement you want to make:

*For voltage measurements, connect the red lead to the positive terminal of the circuit or component.

*For current measurements, connect the red lead in series with the circuit element where you want to measure the current.

*For resistance measurements, connect the red lead to one terminal of the resistor and the black lead to the other terminal.

3. Set the Function Selector Knob:

Rotate the function selector knob to the desired measurement type, such as voltage (V), current (A), or resistance (Ω).

4. Set the Range Selector Knob:

Choose the appropriate measurement range based on the expected value of the parameter you are measuring. Start with a higher range and gradually decrease it until you get a stable reading on the display.

5. Take the Measurement:

-

Touch the probe tips of the test leads to the appropriate points on the circuit or component being measured.

-

Observe the reading on the display. The reading will indicate the value of the parameter you are measuring.

6. Interpret the Reading:

-

Pay attention to the units displayed along with the reading, such as volts (V) for voltage, amps (A) for current, and ohms (Ω) for resistance.

-

Consider the polarity for voltage measurements. A positive reading indicates that the red test lead is connected to the positive terminal, while a negative reading indicates that it is connected to the negative terminal.

7. Disconnect the Test Leads:

Once the measurement is complete, disconnect the test leads from the circuit or component.

What's the difference between handheld and benchtop digital multimeters?

Handheld digital multimeters, like those manufactured by Fluke, are used by electricians, electrical contractors and HVAC specialists to make measurements and troubleshoot potentially hazardous systems in the field. Benchtop multimeters, like those made by Keithley, are instruments used by electrical and electronic engineers to perform more advanced measurements and gain confidence in their designs. These instruments are extremely precise and have a variety of advanced functionality, including the ability to program automation, slow or speed up measurements to observe low-level or transient signal behavior, and interface with other instruments.

Can Keithley digital multimeters be rack mounted?

Yes, Keithley digital multimeters can be rack mounted with the appropriate kit.

What are the safety precautions when using a digital multimeter?

When using a digital multimeter, it is important to follow safety precautions to avoid electrical hazards:

-

Always read the user manual carefully before using the DMM.

-

Always use the appropriate voltage and current ranges for the circuit you are measuring.

-

Never touch exposed wires or components while the DMM is connected to a circuit.

-

Always work in a well-lit and ventilated area.

-

Wear proper personal protective equipment (PPE), such as safety glasses and gloves, when working with electrical circuits.

-

Never use a DMM that is damaged or malfunctioning.