The 2281S’s Role in Wireless Device Testing

According to the National Science Foundation, wireless broadband communications networks have become an essential component of society, and breakthrough innovations in wireless communications increase the ability of people, government, and businesses to interact with one another, supporting technological, economic, and social growth (National Science Foundation , 2021).

The demand for wireless devices we use to communicate has increased and the Center for Information Technology Accommodation (CITA), predicts that by 2023, the number of connected wireless devices including wearables, will reach approximately 31 billion (CITA, 2017). As the number of wireless devices continues to climb, research and design (R&D) engineers are needed for specialized battery testing applications in order to get wireless (IoT) devices into the hands of consumers.

During testing, R&D engineers are faced with the challenge of maximizing the battery life for wireless applications. Therefore, power management is a primary concern in IoT (wireless device) design and in user experience.

The battery life of IoT devices varies greatly, from hours to years, depending on the application and operating environment. In all cases, however, the ability to accurately describe the device’s power consumption is essential. Robust power analysis helps designers identify opportunities to reduce energy consumed and optimize battery life.

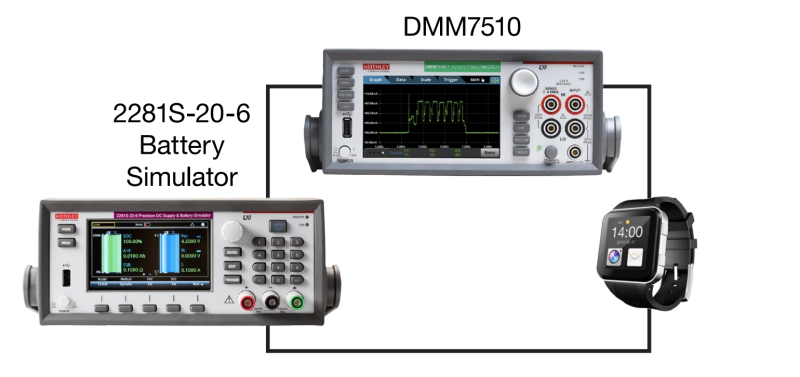

Figure 1: 2281S Battery Charger/Simulator

Keithley Instruments offers a tool specifically designed for the testing of wireless devices. The Series 2281S Battery Simulator and Precision DC Power Supply innovatively integrates battery simulation with the functions of a high-precision power supply. The 2281S-20-6 can analyze the DC current consumption of a device under test and generate a battery model based on a battery charging process, and simulate a battery based on a battery model. The 2281S-20-6 can also output 120 W with 20 V and 6 A, and sink current up to 1 A.

Keithley’s 2281S-20-6 Battery Simulator makes it easy to model any type of battery required, so testing prototype devices can be done efficiently and with high repeatability at any battery state, as well as estimating battery life effectively. Combining a 2281S-20-6 with a DMM7510 provides a complete solution for power consumption/battery life assessment.

Figure 2: Power Profiling & Battery Life Analysis

Figure two shows a power profiling analysis test configuration for a wearable wireless device. In the image, the 2281S is taking the place of the battery and the application is focused on verifying the device's power budge or average power. The test will almost always need more accuracy, a greater degree of sample time resolution, or both for the current measurement. Integrating the DMM into the testing circuit provides faster measurement speeds and better measurement accuracy using either the integrating ADC (analog to digital converter) or digitizer. The 2281S can acquire current and help to get to average power, but the addition of the DMM helps to take things to the next level. Source Measure Units are also commonly used in place of the power supply; however, many customers still opt for adding the DMM.

The 2281S uses linear regulation to ensure low-output noise and superior load current measurement sensitivity. A high-resolution color thin film transistor (TFT) screen displays a wide range of information on measurements. Soft-key buttons and a navigation wheel combine with the TFT display to provide an easy-to-navigate user interface that accelerates instrument setup and operation. In addition, built-in plotting functions allow monitoring trends such as drift. These features provide the flexibility required for both benchtop and automated test system applications. In addition, the 2281S provides a list mode, triggers, and other speed optimization functions to minimize test time in automated testing applications.

In the battery simulator function of the 2281S which is pictured in Figures 1 and 2, real battery output performance can be simulated based on a selected battery model. State of charge (SOC) and voltage open circuit (Voc) can be set to any state to test a device under-test’s (DUT’s) performance at various states of the battery. There are two modes that users can choose from: Static and Dynamic. During the Static simulation, Voc and SOC stay the same, while during the Dynamic simulation, Voc and SOC change according to charging and discharging as with a real battery. Capacity can also be reduced to accelerate the charging and discharging process for better test efficiency.

As the number of wireless devices rises into the billions, Keithley Instruments will continue to support the wireless device industry by offering specialized and innovative testing equipment to support R&D engineering applications. To learn more about the Series 2281S Battery Simulator and Precision DC Power Supply and other specialized wireless device testing products, please visit us at Tek.com/Keithley.

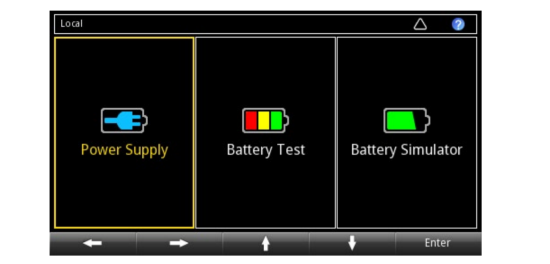

Figure 3: 2281S Startup Screen

Figure 4: Battery Simulator Home Screen

References

CITA. (2017). The Wireless Industry. Retrieved from Industry Data: https://www.ctia.org/the-wireless-industry/infographics-library#:~:text=Data%20Traffic%2019.6%25-,2020%20Wireless%20Use%20Surge,nearly%20overnight%20spikes%20in%20demand.

National Science Foundation . (2021, April). Advanced Wireless Reseach Initiation. Retrieved from Advanced Wireless Research at NSF: https://www.nsf.gov/cise/advancedwireless/