Contactez-nous

Chat en direct avec un représentant Tek. Service disponible de 9 h à 17 h, CET jours ouvrables.

Appelez-nous au

Disponible de 9 h à 17 h CET jours ouvrables.

Télécharger

Télécharger des manuels, des fiches techniques, des logiciels, etc. :

Feedback

ABCs of Probes Primer

ABCs of Probes Primer

Learn about the fundamentals of probes and discover how to choose the right probe for your oscilloscope and get reliable measurements every time in this comprehensive ABCs of Probes primer.

= = = = = = = = = = = = = =

1. Probing Safety

Safety Summary

When making measurements on electrical or electronic systems or circuitry, personal safety is of paramount importance. Be sure that you understand the capabilities and limitations of the measuring equipment that you’re using. Also, before making any measurements, become thoroughly familiar with the system or circuitry that you will be measuring. Review all documentation and schematics for the system being measured, paying particular attention to the levels and locations of voltages in the circuit and heeding any and all cautionary notations.

Additionally, be sure to review the following safety precautions to avoid personal injury and to prevent damage to the measuring equipment or the systems to which it is attached. For additional explanation of any of the following precautions, please refer to Explanation of Safety Precautions.

- Observe All Terminal Ratings

- Use Proper Grounding Procedures

- Connect and Disconnect Probes Properly

- Avoid Exposed Circuitry

- Avoid RF Burns While Handling Probes

- Do Not Operate Without Covers

- Do Not Operate in Wet/Damp Conditions

- Do Not Operate in an Explosive Atmosphere

- Do Not Operate with Suspected Failures

- Keep Probe Surfaces Clean and Dry

- Do Not Immerse Probes in Liquids

Explanation of Safety Precautions

Review the following safety precautions to avoid injury and to prevent damage to your test equipment or any product that it is connected to. To avoid potential hazards, use your test equipment only as specified by the manufacturer.

Keep in mind that all voltages and currents are potentially dangerous, either in terms of personal hazard, damage to equipment, or both.

Observe All Terminal Ratings

- To avoid fire or shock hazard, observe all ratings and markings on the product. Consult the product manual for further ratings information before making connections to the product.

- Do not apply a potential to any terminal that exceeds the maximum rating of that terminal.

- Connect the ground lead of probes to earth ground only

Caution

For those scopes that are specifically designed and specified to operate in a floating oscilloscope application, the second lead is a common lead and not a ground lead. In this case, follow the manufacturer’s specification for maximum voltage level that this can be connected to.

- Check probe and test equipment documentation for any derating information. For example, the maximum input voltage rating may decrease with increasing frequency

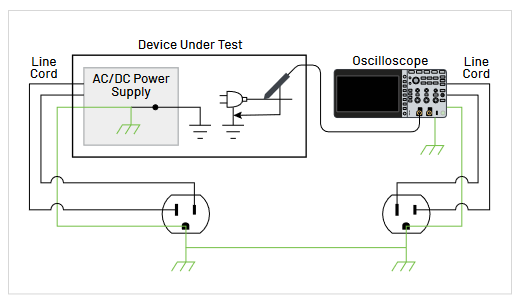

Use Proper Grounding Procedures

- Probes are indirectly grounded through the grounding conductor of the oscilloscope power cord. To avoid electric shock, the grounding conductor must be connected to earth ground. Before making connections to the input or output terminals of the product, ensure that the product is properly grounded.

- Never attempt to defeat the power cord grounds of any test equipment.

- Connect probe ground leads to earth ground only.

- Isolation of an oscilloscope from ground that is not specifically designed and specified for this type of operation, or connecting a ground lead to anything other than ground could result in dangerous voltages being present on the connectors, controls, or other surfaces of the oscilloscope and probes.

Caution

The above statement is true for most scopes,but there are some scopes that are designed and specified to operate in floating applications.

Connect and Disconnect Probes Properly

- Connect the probe to the oscilloscope first. Then properly ground the probe before connecting the probe to any test point.

- Probe ground leads should be connected to earth ground only.

- When disconnecting probes from the circuit under test, remove the probe tip from the circuit first, then disconnect the ground lead.

- With the exception of the probe tip and the probe connector center conductor, all accessible metal on the probe (including the ground clip) is connected to the connector shell.

Avoid Exposed Circuitry

- Avoid touching exposed circuitry or components with your hands or any other part of your body.

- Make sure that probe tips and ground lead clips are attached such that they do not accidentally brush against each other or other parts of the circuit under test.

Avoid RF Burns While Handling Probes

- When RF power is present, resonances and reactive effects can transform even small voltages into potentially harmful or dangerous voltages.

- If you need to use a probe within the risk area for RF burn, turn power off to the source before connecting or disconnecting the probe leads. Do not handle the input leads while the circuit is active.

Do Not Operate Without Covers

- Oscilloscopes and probes should not be operated with any cover or protective housing removed. Removing covers, shielding, probe bodies, or connector housings will expose conductors or components with potentially hazardous voltages.

Do Not Operate in Wet/Damp Conditions

- To avoid electrical shock or damage to equipment, do not operate measurement equipment in wet or damp conditions.

Do Not Operate in an Explosive Atmosphere

- Operating electrical or electronic equipment in an explosive atmosphere could result in an explosion. Potentially explosive atmospheres may exist wherever gasoline, solvents, ether, propane, and other volatile substances are in use, have been in use, or are being stored. Also, some fine dusts or powders suspended in the air may present an explosive atmosphere.

Do Not Operate with Suspected Failures

- If you suspect there’s damage, either electrical or physical, to an oscilloscope or probe, have it inspected by qualified service personnel before continuing usage.

Keep Probe Surfaces Clean and Dry

- Moisture, dirt, and other contaminants on the probe surface can provide a conductive path. For safe and accurate measurements, keep probe surfaces clean and dry.

- Probes should be cleaned using only the procedures specified in the probe’s documentation.

Do Not Immerse Probes in Liquids

- Immersing a probe in a liquid could provide a conductive path between internal components, resulting in damage or corrosion to the internal components or the outer body and shielding.

- Probes should be cleaned using only the procedures specified in the probe’s documentation.

2. Precision Measurements Start at the Probe Tip

Probes are vital to oscilloscope measurements. To understand how vital, disconnect the probes from an oscilloscope and try to make a measurement. It can’t be done. There has to be some kind of electrical connection — a probe of some sort — between the signal to be measured and the oscilloscope's input channel.

In addition to being vital to oscilloscope measurements, probes are also critical to measurement quality. Connecting a probe to a circuit can affect the operation of the circuit; an oscilloscope can only display and measure the signal that the probe delivers to the oscilloscope input.

Thus, it is imperative that the probe have minimum impact on the probed circuit, and that it maintain adequate signal fidelity for the desired measurements.

If the probe doesn’t maintain signal fidelity or changes the way a circuit operates, the oscilloscope sees a distorted version of the actual signal. The result can be wrong or misleading measurements.

In essence, the probe is the first link in the oscilloscope measurement chain, and the strength of this measurement chain relies as much on the probe as the oscilloscope. Weaken that first link with an inadequate probe or poor probing methods, and the entire chain is weakened.

In this and the following sections, you’ll learn what contributes to the strengths and weaknesses of probes and how to select the right probe for your application. You’ll also learn some important tips for using probes properly

What Is a Probe?

As a first step, let’s establish what an oscilloscope probe is. A probe makes a physical and electrical connection between a test point or signal source and an oscilloscope. Depending on your measurement needs, this connection can be made with something as simple as a length of wire, or with something as sophisticated as an active differential probe.

At this point, it’s enough to say that an oscilloscope probe is some sort of device or network that connects the signal source to the input of the oscilloscope.

Whatever the probe is in reality, it must provide a connection of adequate convenience and quality between the signal source and the oscilloscope input (Figure 2.1). The adequacy of connection has three key defining issues: physical attachment, impact on circuit operation, and signal transmission.

To make an oscilloscope measurement, you must first be able to physically get the probe to the test point. To make this possible, most probes have at least a meter or two of cable associated with them, as indicated in Figure 2.1. This probe cable allows the oscilloscope to be left in a stationary position on a cart or bench top while the probe is moved from test point to test point in the circuit being tested. There is a tradeoff for this convenience, though. The probe cable reduces the probe’s bandwidth. The longer the cable, the greater the reduction.

In addition to the length of cable, most probes also have a probe head, or handle, with a probe tip. The probe head allows you to hold the probe while you maneuver the tip to make contact with the test point. Often, this probe tip is in the form of a spring-loaded hook that allows you to easily attach the probe to the test point.

Physically attaching the probe to the test point also establishes an electrical connection between the probe tip and the oscilloscope input. For useable measurement results, attaching the probe to a circuit must have minimum effect on the way the circuit operates, and the signal at the probe tip must be transmitted with adequate fidelity through the probe head and cable to the oscilloscope’s input.

These three issues — physical attachment, minimum impact on circuit operation, and adequate signal fidelity — encompass most of what goes into proper selection of a probe. Because probing effects and signal fidelity are the more complex topics, much of this primer is devoted to those issues. However, the issue of physical connection should never be ignored. Difficulty in connecting a probe to a test point often leads to probing practices that reduce fidelity.

The Ideal Probe

In an ideal world, the ideal probe would offer the following key attributes:

- Connection ease and convenience

- Absolute signal fidelity

- Zero signal source loading

- Complete noise immunity

Connection Ease and Convenience

Making a physical connection to the test point has already been mentioned as one of the key requirements of probing. With the ideal probe, you should also be able to make the physical connection with both ease and convenience.

For miniaturized circuitry, such as surface mount technology (SMT), connection ease and convenience are promoted through subminiature probe heads and various probe-tip adapters designed for SMT devices.

Such a probing system is shown in Figure 2.2a. These probes, however, are too small for practical use in applications such as industrial power circuitry where high voltages and larger gauge wires are common. For power applications, physically larger probes with greater margins of safety are required. Figures 2.2b and 2.2c show examples of such probes, where Figure 2.2b is a high-voltage probe and Figure 2.2c is a clamp-on current probe.

Figure 2.2. Various probes are available for different application technologies and measurement needs.

From these few examples of physical connection, it’s clear that there’s no single ideal probe size or configuration for all applications. Because of this, various probe sizes and configurations have been designed to meet the physical connection requirements of various applications.

Absolute Signal Fidelity

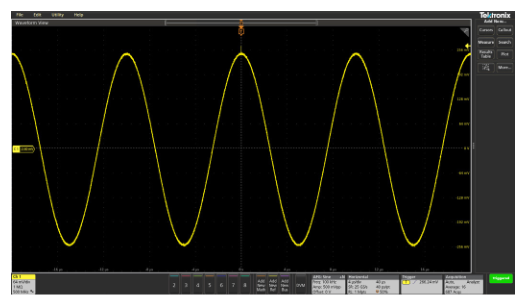

The ideal probe should transmit any signal from probe tip to oscilloscope input with absolute signal fidelity. In other words, the signal as it occurs at the probe tip should be faithfully duplicated at the oscilloscope input.

For absolute fidelity, the probe circuitry from tip to oscilloscope input must have zero attenuation, infinite bandwidth, and linear phase across all frequencies. Not only are these ideal requirements impossible to achieve in reality, but they are impractical. For example, there’s no need for an infinite bandwidth probe or oscilloscope when dealing with audio frequency signals. In addition, there is no need for infinite bandwidth when 500 MHz is sufficient for covering most high-speed digital, TV, and other typical oscilloscope applications.

Still, within a given bandwidth of operation, absolute signal fidelity is an ideal to be sought after.

Zero Signal Source Loading

The circuitry behind a test point can be thought of as or modeled as a signal source. Any external device, such as a probe, that’s attached to the test point can appear as an additional load on the signal source behind the test point.

The external device acts as a load when it draws signal current from the circuit (the signal source). This loading, or signal current draw, changes the operation of the circuitry behind the test point, and thus changes the signal seen at the test point.

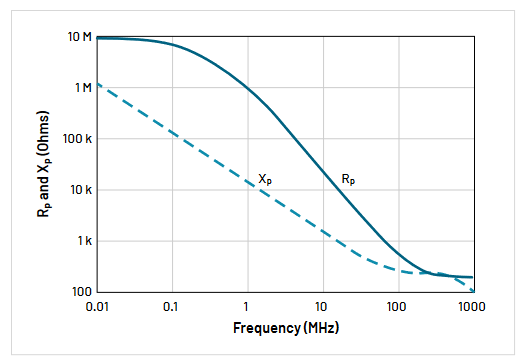

An ideal probe causes zero signal source loading. In other words, it doesn’t draw any signal current from the signal source. This means that, for zero current draw, the probe must have infinite impedance, essentially presenting an open circuit to the test point.

In practice, a probe with zero signal source loading cannot be achieved. This is because a probe must draw some small amount of signal current in order to develop a signal voltage at the oscilloscope input. Consequently, some signal source loading is to be expected when using a probe. The goal, however, should always be to minimize the amount of loading by selecting the appropriate probe.

Complete Noise Immunity

Fluorescent lights and fan motors are just two of the many electrical noise sources in our environment. These sources can induce their noise onto nearby electrical cables and circuitry, causing the noise to be added to signals. Because of susceptibility to induced noise, a simple piece of wire is a less than ideal choice for an oscilloscope probe.

The ideal oscilloscope probe is completely immune to all noise sources. As a result, the signal delivered to the oscilloscope has no more noise on it than what appeared on the signal at the test point.

In practice, use of shielding allows probes to achieve a high level of noise immunity for most common signal levels. Noise, however, can still be a problem for certain low-level signals. In particular, common mode noise can present a problem for differential measurements, as will be discussed later.

The Realities of Probes

The preceding discussion of The Ideal Probe mentioned several realities that keep practical probes from reaching the ideal. To understand how this can affect your oscilloscope measurements, we need to explore the realities of probes further.

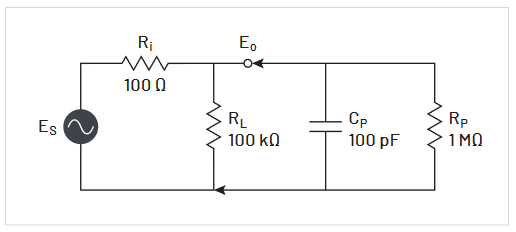

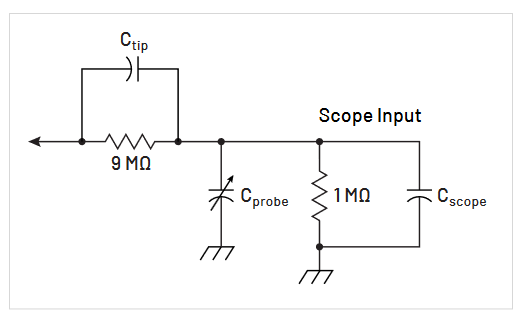

First, it’s important to realize that a probe, even if it’s just a simple piece of wire, is potentially a very complex circuit. For DC signals (0 Hz frequency), a probe appears as a simple conductor pair with some series resistance and a terminating resistance (Figure 2.3a). However, for AC signals, the picture changes dramatically as signal frequencies increase (Figure 2.3b).

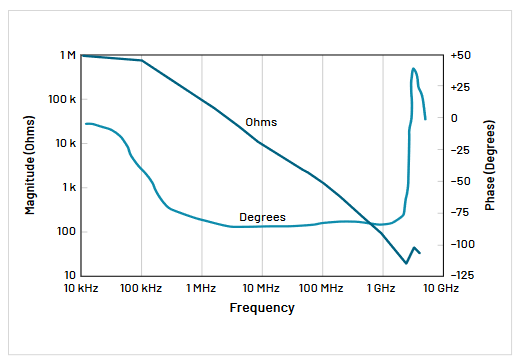

The picture changes for AC signals because any piece of wire has distributed inductance (L), and any wire pair has distributed capacitance (C). The distributed inductance reacts to AC signals by increasingly impeding AC current flow as signal frequency increases. The distributed capacitance reacts to AC signals with decreasing impedance to AC current flow as signal frequency increases. The interaction of these reactive elements (L and C), along with the resistive elements (R), produces a total probe impedance that varies with signal frequency. Through good probe design, the R, L, and C elements of a probe can be controlled to provide desired degrees of signal fidelity, attenuation, and source loading over specified frequency ranges. Even with good design, probes are limited by the nature of their circuitry. It’s important to be aware of these limitations and their effects when selecting and using probes.

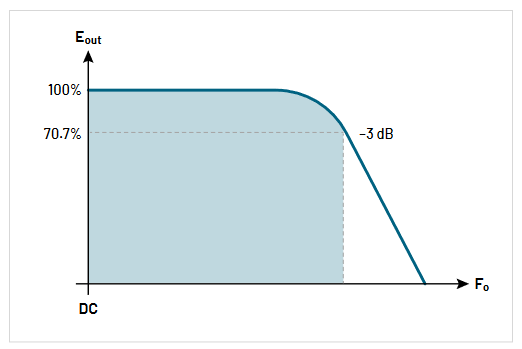

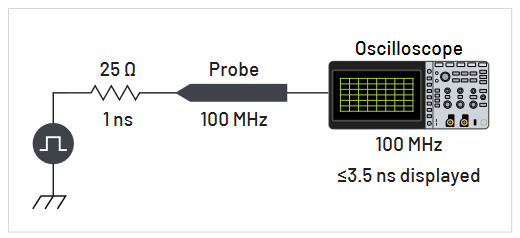

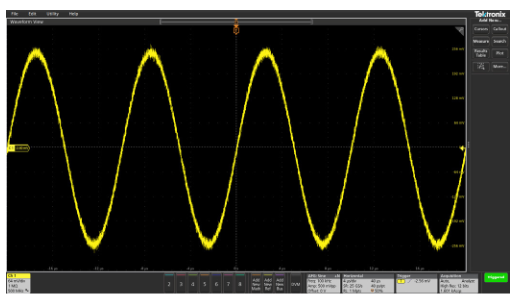

Bandwidth and Rise Time Limitations

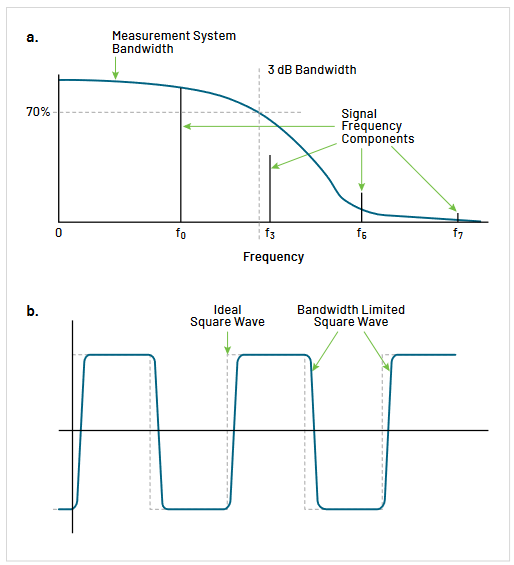

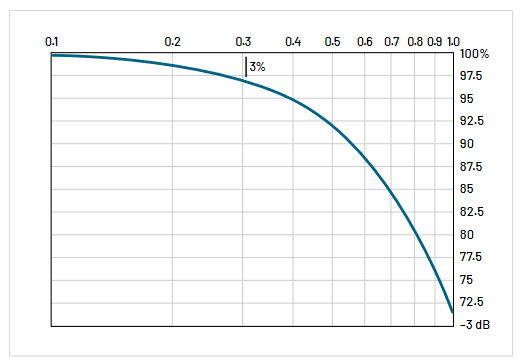

Bandwidth is the range of frequencies that an oscilloscope or probe is designed for. For example, a 100 MHz probe or oscilloscope is designed to make measurements within specification on all frequencies up to 100 MHz. Unwanted or unpredictable measurement results can occur at signal frequencies above the specified bandwidth (Figure 2.4). As a general rule, for accurate amplitude measurements, the bandwidth of the oscilloscope should be three to five times greater than the frequency of the waveform being measured. This improves the accuracy of amplitude measurements by staying clear of the 3 dB attenuation frequency as shown in Figure 2.4. For a system with a first order (Gaussian) rolloff, the measured amplitude at the -3 dB point is about 70% of the actual amplitude. Some high-performance oscilloscopes and probes have a steeper rolloff, and will produce more accurate amplitude measurements closer to their rated bandwidth. Using a probe/scope combination with five times the bandwidth of the frequency of your signal will deliver accurate amplitude measurements without concern.

It is also important to remember that the graph in Figure 2.4 applies to pure sinewaves. The maximum frequency components of square waves and pulses are harmonics of the fundamental frequency of the signal. To get an accurate view of a square wave, one must be able to see the fifth harmonic or even the seventh.

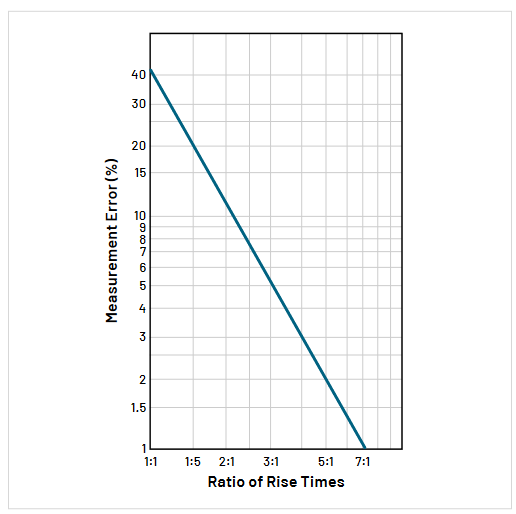

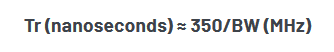

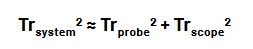

Similarly, the oscilloscope must have an adequate rise time for the waveforms being measured. The rise time of an oscilloscope or probe is defined as the time it takes the pulse to rise from the 10% amplitude level to the 90% amplitude level. For reasonable accuracy in measuring pulse rise or fall times, the rise time of the probe and oscilloscope together should be three to five times faster than that of the pulse being measured (Figure 2.5).

Every oscilloscope has defined bandwidth and rise time limits. Similarly, every probe also has its own set of bandwidth and rise time limits. When a probe is attached to an oscilloscope, you get a new set of system bandwidth and rise time limits.

Unfortunately, the relationship between system bandwidth and the individual oscilloscope and probe bandwidths is not a simple one. The same is true for rise times. To cope with this, manufacturers of quality oscilloscopes specify bandwidth or rise time to the probe tip when the oscilloscope is used with specific probe models. This is important because the oscilloscope and probe together form a measurement system, and it’s the bandwidth and rise time of the system that determine its measurement capabilities. If you use a probe that is not on the oscilloscope’s recommended list of probes, you run the risk of unpredictable measurement results.

Dynamic Range Limitations

All probes have a high-voltage safety limit that should not be exceeded. For passive probes, this limit can range from hundreds of volts to thousands of volts. However, for active probes, the maximum safe voltage limit is often in the range of tens of volts. To avoid personal safety hazards, as well as potential damage to the probe, it’s wise to be aware of the voltages being measured and the voltage limits of the probes being used.

In addition to safety considerations, there’s also the practical consideration of measurement dynamic range. Oscilloscopes have amplitude sensitivity ranges. For example, 1 mV to 10 V/division is a typical sensitivity range. On an eight-division display, this means that you can typically make reasonably accurate measurements on signals ranging from 4 mV peak-to-peak to 40 V peak-to-peak.

This assumes, at minimum, a four-division amplitude display of the signal to obtain reasonable measurement resolution. With a 1X probe (1-times probe), the dynamic measurement range is the same as that of the oscilloscope. For the example above, this would be a signal measurement range of 4 mV to 40 V.

With a 1X probe (1-times probe), the dynamic measurement range is the same as that of the oscilloscope. For the example above, this would be a signal measurement range of 4 mV to 40 V.

But, what if you need to measure a signal beyond the 40 V range?

You can shift the oscilloscope’s dynamic range to higher voltages by using an attenuating probe. A 10X probe, for example, shifts the dynamic range to 40 mV to 400 V. It does this by attenuating the input signal by a factor of 10, which effectively multiplies the oscilloscope’s scaling by 10. For most general-purpose use, 10X probes are preferred, both because of their high-end voltage range and because they cause less signal source loading. However, if you plan to measure a very wide range of voltage levels, you may want to complement the 10X probe with a 1X probe. This combination gives you a dynamic range of 4 mV to 400 V. However, in the 1X mode, more care must be taken with regard to signal source loading.

Source Loading

As previously mentioned, a probe must draw some signal current in order to develop a signal voltage at the oscilloscope input. This places a load at the test point that can change the signal that the circuit, or signal source, delivers to the test point.

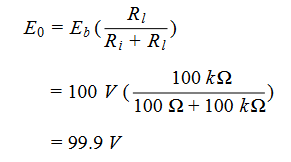

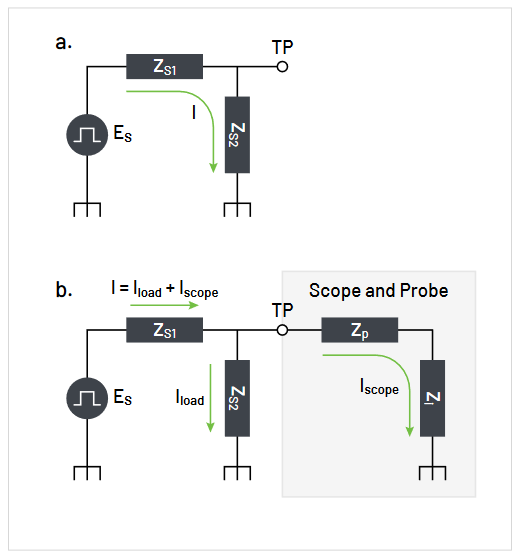

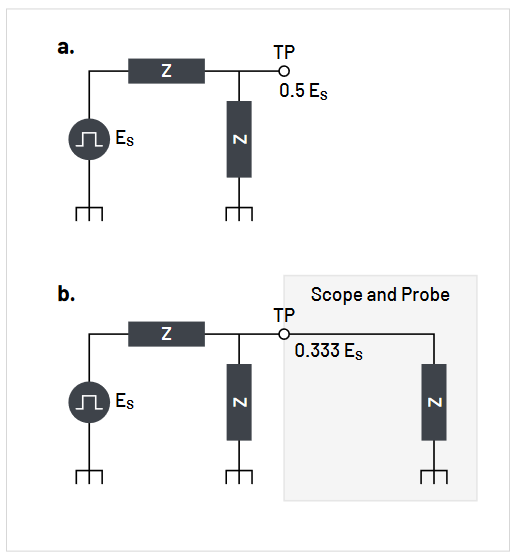

The simplest example of source loading effects is to consider measurement of a battery-driven resistive network. This is shown in Figure 2.7. In Figure 2.7a, before a probe is attached, the battery’s DC voltage is divided across the battery’s internal resistance (Ri) and the load resistance

(Ri) that the battery is driving. For the values given in the diagram, this results in an output voltage of:

In Figure 2.7b, a probe has been attached to the circuit, placing the probe resistance (Rp) in parallel with RI . If Rp is 100 kΩ, the effective load resistance in Figure 2.7b is cut in half to 50 kΩ.

The loading effect of this on Eo is:

This loading effect of 99.9 V versus 99.8 V is only 0.1% and is negligible for most purposes. However, if the resistance of the probe (Rp) were smaller, say 10 kΩ, the effect would no longer be negligible.

To minimize such resistive loading, 1X probes typically have a resistance of 1 MΩ, and 10X probes typically have a resistance of 10 MΩ. For most cases, these values result in negligible resistive loading. Some loading should be expected, though, when measuring high-resistance sources.

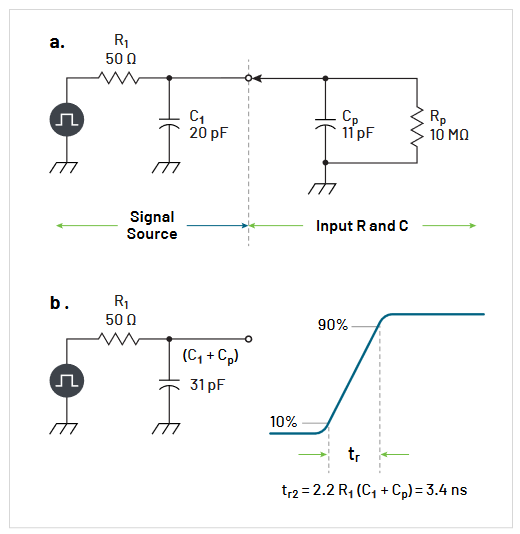

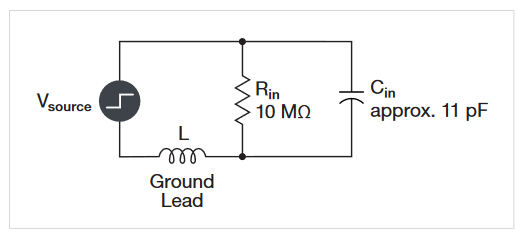

Usually, the loading of greatest concern is that caused by the capacitance at the probe tip (see Figure 2.8). For low frequencies, this capacitance has a reactance that is very high, and there’s little or no effect. But, as frequency increases, the capacitive reactance decreases. The result is increased loading at high frequencies.

This capacitive loading affects the bandwidth and rise time characteristics of the measurement system by reducing bandwidth and increasing rise time.

Capacitive loading can be minimized by selecting probes with low tip capacitance values. Some typical capacitance values for various probes are provided in the table below:

| Probe | Attenuation | R | C |

| P6101B | 1X | 1 MΩ | 100 pF |

| P6139B | 10X | 10 MΩ | 8 pF |

| P6243 | 10X | 1 MΩ | ≤1 pF |

| TPP1000 | 10X | 10 MΩ | 12 pF |

Table 1.1. Probe capacitance.

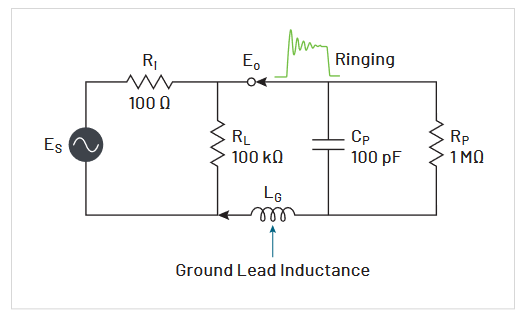

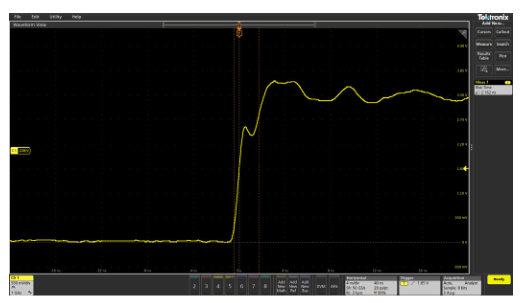

Since the ground lead is a wire, it has some amount of distributed inductance (see Figure 2.9). This inductance interacts with the probe capacitance to cause ringing at a certain frequency that is determined by the L and C values. This ringing is unavoidable, and may be seen as a sinusoid of decaying amplitude that is impressed on pulses. The effects of ringing can be reduced by designing probe grounding so that the ringing frequency occurs beyond the bandwidth limit of the probe/oscilloscope system.

To avoid grounding problems, always use the shortest ground lead provided with the probe. Substituting other means of grounding can cause ringing to appear on measured pulses.

Probes are Sensors

In dealing with the realities of oscilloscope probes, it’s important to keep in mind that probes are sensors. Most oscilloscope probes are voltage sensors. That is, they sense or probe a voltage signal and convey that voltage signal to the oscilloscope input. However, there are also probes that allow you to sense phenomena other than voltage signals.

For example, current probes are designed to sense the current flowing through a wire. The probe converts the sensed current to a corresponding voltage signal which is then relayed to the input of the oscilloscope. Similarly, optical probes sense light power and convert it to a voltage signal for measurement by an oscilloscope.

Additionally, oscilloscope voltage probes can be used with a variety of other sensors or transducers to measure different phenomena. A vibration transducer, for example, allows you to view machinery vibration signatures on an oscilloscope screen. The possibilities are as wide as the variety of available transducers on the market.

In all cases, though, the transducer, probe, and oscilloscope combination must be viewed as a measurement system. Moreover, the realities of probes discussed above also extend down to the transducer. Transducers have bandwidth limits as well and can cause loading effects.

Some Probing Tips

Selecting probes that match your oscilloscope and application needs gives you the capability for making the necessary measurements. Actually making the measurements and obtaining useful results also depends on how you use the tools. The following probing tips will help you avoid some common measurement pitfalls:

Compensate Your Probes

Most probes are designed to match the inputs of specific oscilloscope models. However, there are slight variations from oscilloscope to oscilloscope, and even between different input channels in the same oscilloscope. To deal with this where necessary, many probes, especially attenuating probes (10X and 100X probes), have built-in compensation networks.

If your probe has a compensation network, you should adjust this network to compensate the probe for the oscilloscope channel that you are using. To do this, use the following procedure:

For Probes Requiring Manual Compensation:

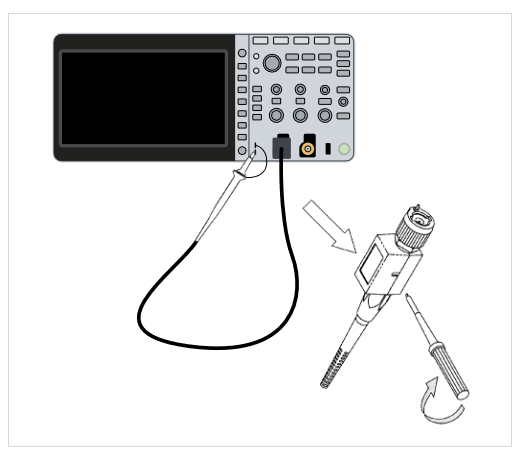

- Attach the probe to the oscilloscope.

- Attach the probe tip to the probe compensation test point on the oscilloscope’s front panel (see Figure 2.10).

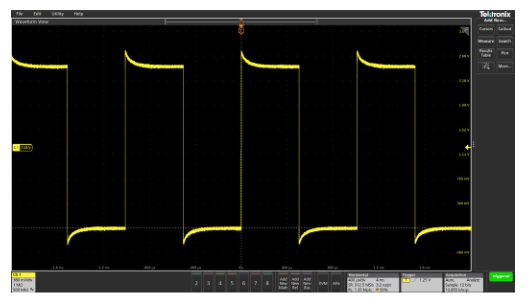

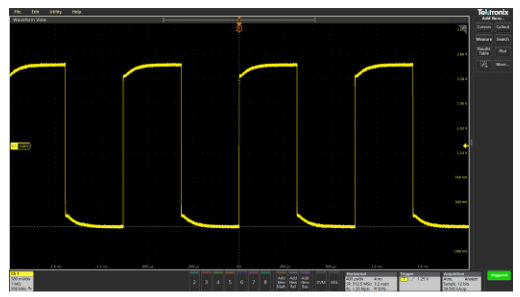

- Use the adjustment tool provided with the probe or other non-magnetic adjustment tool to adjust the compensation network to obtain a calibration waveform display that has flat tops with no overshoot or rounding (see Figure 2.12).

- If the oscilloscope has a built-in calibration routine, run this routine for increased accuracy.

For Modern Probes with Automatic Digital Compensation:

- Attach the probe to the oscilloscope.

- Attach probe tip to the compensation test point on the oscilloscope’s front panel (see Figure 2.10).

- Click the ‘autoset’ button on the front of the oscilloscope.

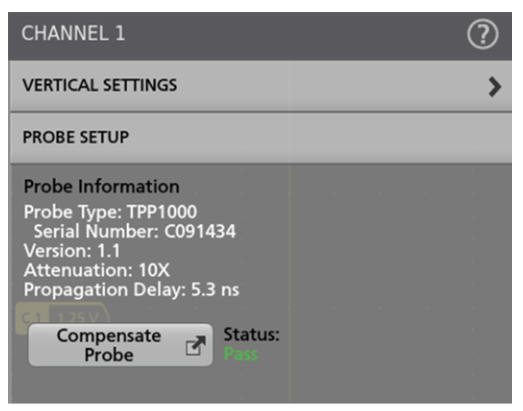

- Double tap or double click the channel badge in the bottom left corner of the screen.

- Navigate to the ‘probe setup’ drop down menu.

- Tap or click the ‘compensate probe’ button (see Figure 2.11).

An uncompensated probe can lead to various measurement errors, especially in measuring pulse rise or fall times. To avoid such errors, always compensate probes right after connecting them to the oscilloscope and check compensation frequently.

Also, it’s wise to check probe compensation whenever you change probe tip adaptors. Some modern oscilloscope “remember” the compensation for specific probes, such as TekVPI probes. For these systems probe compensation can simply be verified with a quick test.

Figure 2.12. Examples of probe compensation effects on a square wave.

Use Appropriate Probe Tip Adapters Whenever Possible

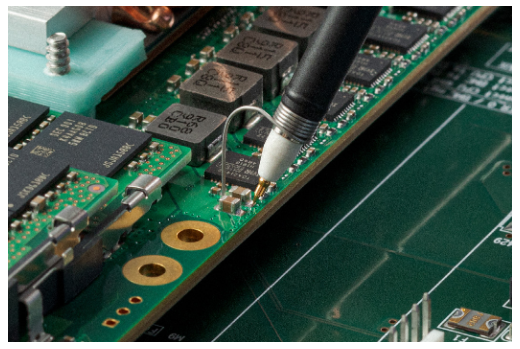

A probe tip adapter that’s appropriate for the circuit being measured makes probe connection quick, convenient, and electrically repeatable and stable. Unfortunately, it’s not uncommon to see short lengths of wire soldered to circuit points as a substitute for a probe tip adapter.

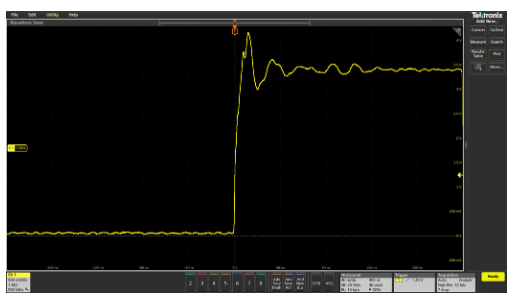

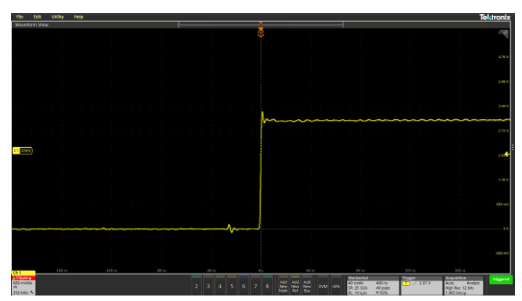

The problem is that even an inch or two of wire can cause significant impedance changes at high frequencies. The effect of this is shown in Figure 2.13, where a circuit is measured by direct contact of the probe tip and then measured via a short piece of wire between the circuit and probe tip.

Figure 2.13. Even a short piece of wire soldered to a test point can cause signal fidelity problems. In this case, rise time has been changed from 4.74 ns to 5.67 ns.

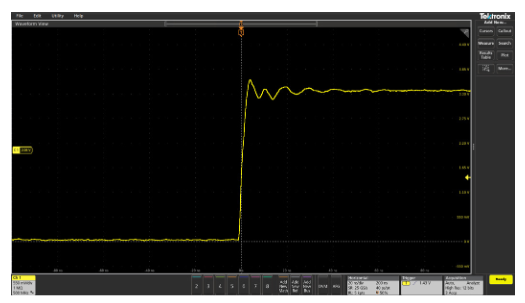

Keep Ground Leads as Short and as Direct as Possible

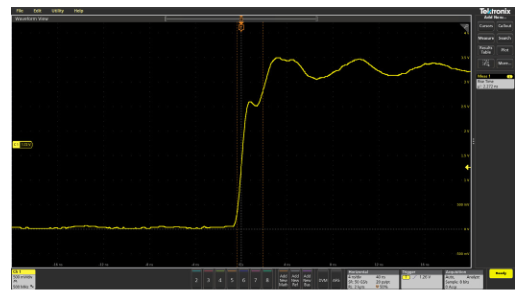

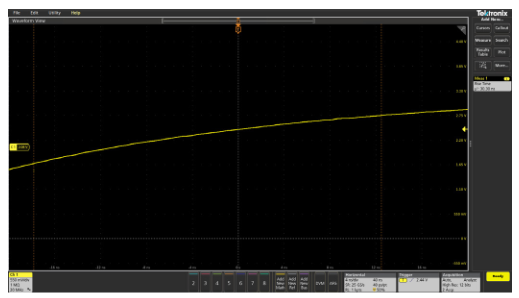

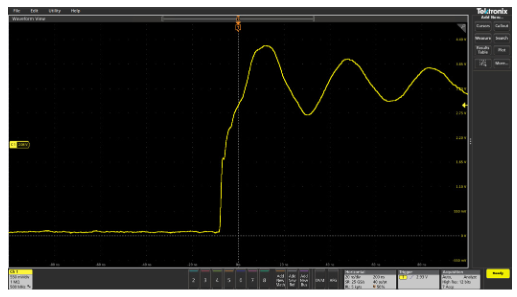

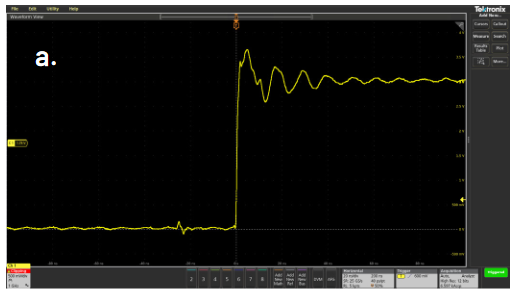

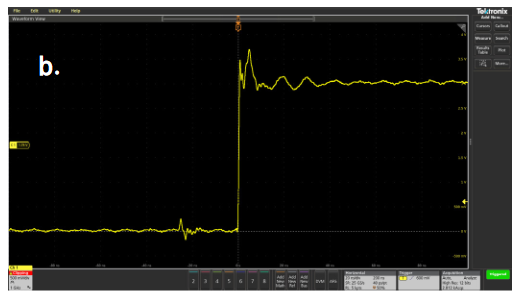

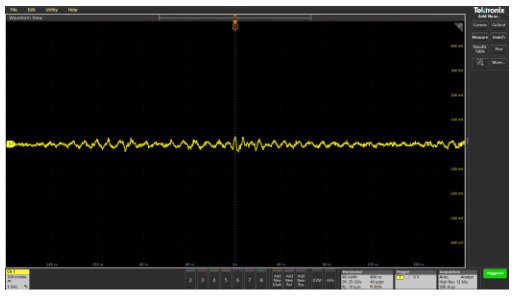

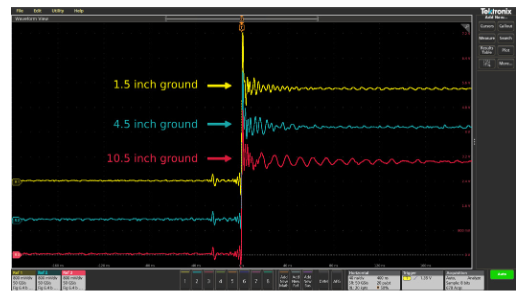

When doing performance checks or troubleshooting large boards or systems, it may be tempting to extend the probe’s ground lead. An extended ground lead allows you to attach the ground once and freely move the probe around the system while you look at various test points. However, the added inductance of an extended ground lead can cause ringing to appear on fast-transition waveforms. This is illustrated in Figure 2.14, which shows waveform measurements made while using the standard probe ground lead and an extended ground lead.

Figure 2.14. Extending the length of the probe ground lead can cause ringing to appear on pulses.

Summary

In this first chapter, we’ve tried to provide all of the basic information necessary for making appropriate probe selections and using probes properly. In the following chapters, we’ll expand on this information as well as introduce more advanced information on probes and probing techniques.

3. Different Probes for Different Needs

Hundreds, perhaps even thousands, of different oscilloscope probes are available on the market.

Is such a broad selection of probes really necessary? The answer is yes, and in this chapter you’ll discover the reasons why

With an understanding of those reasons, you’ll be better prepared to make probe selections to match both the oscilloscope you are using and the type of measurements that you need to make. The benefit is that proper probe selection leads to enhanced measurement capabilities and results.

Why So Many Probes?

The wide selection of oscilloscope models and capabilities is one of the fundamental reasons for the number of available probes. Different oscilloscopes require different probes. A 400 MHz oscilloscope requires probes that will support that 400 MHz bandwidth.

However, those same probes would be overkill in capability and cost for a 100 MHz oscilloscope. Thus, a different set of probes designed to support a 100 MHz bandwidth is needed.

As a general rule, probes should be selected to match the oscilloscope’s bandwidth whenever possible. If matching the oscilloscope’s bandwidth isn’t a possibility, choose to exceed the oscilloscope’s bandwidth.

Bandwidth is just the beginning, though. Oscilloscopes can also have different input connector types and different input impedances. For example, most scopes use a simple BNC-type input connector. Others may use an SMA connector. And still others, as shown in Figure 3.1, have specially designed connectors to support readout, trace ID, probe power, or other special features.

Thus, probe selection must also include connector compatibility with the oscilloscope being used. This can be direct connector compatibility, or connection through an appropriate adaptor.

Figure 3.1. Probe to oscilloscope interfaces

|

|

|

|

|

|

|

|

|

|

|

Readout support is a particularly important aspect of probe/oscilloscope connector compatibility. When 1X and 10X probes are interchanged on an oscilloscope, the oscilloscope’s vertical scale readout should reflect the 1X to 10X change. For example, if the oscilloscope’s vertical scale readout is 1 V/div (one volt per division) with a 1X probe attached, and you change to a 10X probe, the vertical readout should change by a factor of 10 to 10 V/div. If this 1X to 10X change is not reflected in the oscilloscope’s readout, amplitude measurements made with the 10X probe will be ten times lower than they should be.

Some generic or commodity probes may not support readout capability for all scopes. As a result, extra caution is necessary when using generic probes in place of the probes specifically recommended by the oscilloscope manufacturer.

In addition to bandwidth and connector differences, various scopes also have different input resistance and capacitance values. Typically, oscilloscope input resistances are either 50 Ω or 1 MΩ. However, there can be great variations in input capacitance depending on the oscilloscope’s bandwidth specification and other design factors. For proper signal transfer and fidelity, it’s important that the probe’s resistance and capacitance values match the resistance and capacitance values of the oscilloscope it is to be used with. For example, 50 Ω probes should be used with 50 Ω oscilloscope inputs. Similarly, 1 MΩ probes should be used on scopes with a 1 MΩ input resistance.

An exception to this one-to-one resistance matching occurs when attenuator probes are used. For example, a 10X probe for a 50 Ω environment will have a 500 Ω input resistance, and a 10X probe for a 1 MΩ environment will have a 10 MΩ input resistance. (Attenuator probes, such as a 10X probe, are also referred to as divider probes and multiplier probes. These probes multiply the measurement range of the oscilloscope. They do this by attenuating or dividing down the input signal supplied to the oscilloscope.)

In addition to resistance matching, the probe’s capacitance should also match the nominal input capacitance of the oscilloscope. Often, this capacitance matching can be done through adjustment of the probe’s compensation network. This is only possible, though, when the oscilloscope’s nominal input capacitance is within the compensation range of the probe. Thus, it’s not unusual to find probes with different compensation ranges to meet the requirements of different oscilloscope inputs.

The issue of matching a probe to an oscilloscope has been tremendously simplified by oscilloscope manufacturers. Oscilloscope manufacturers carefully design probes and oscilloscopes as complete systems. As a result, the best probe-to-oscilloscope match is always obtained by using the standard probe specified by the oscilloscope manufacturer. Use of any probe other than the manufacturer-specified probe may result in less than optimum measurement performance.

Probe-to-oscilloscope matching requirements alone generate much of the basic probe inventory available on the market. This probe count is then added to significantly by the different probes that are necessary for different measurements needs. The most basic differences are in the voltage ranges being measured. Millivolt, volt, and kilovolt measurements typically require probes with different attenuation factors (1X, 10X, 100X).

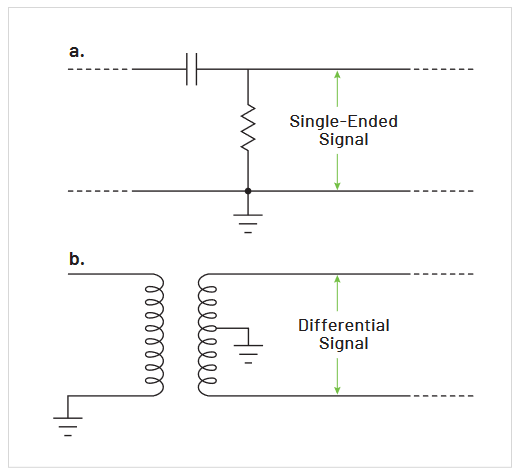

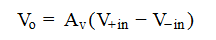

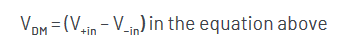

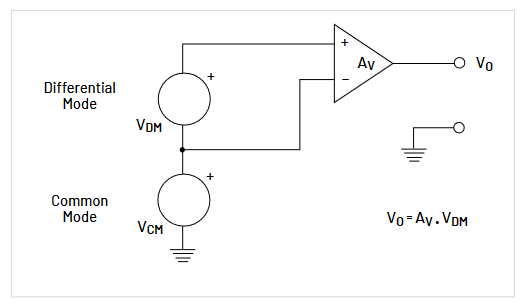

Also, there are many cases where the signal voltages are differential. That is, the signal exists across two points or two wires, neither of which is at ground or common potential (see Figure 3.2). Such differential signals are common in amplifier circuits, serial data communications, and power circuits. Measuring these signals requires yet another class of probes referred to as differential probes.

There are many cases, particularly in power applications, where current is of as much or more interest than voltage. Such applications are best served with yet another class of probes that sense current rather than voltage.

Current probes and differential probes are just two special classes of probes among the many different types of available probes. The rest of this chapter covers some of the more common types of probes and their special benefits.

Different Probe Types and Their Benefits

As a preface to discussing various common probe types, it’s important to realize that there’s often overlap in types. Certainly a voltage probe senses voltage exclusively, but a voltage probe can be a passive probe, or an active probe. Similarly, differential probes are a special type of voltage probe, and differential probes can also be active or passive probes. These overlapping relationships will be pointed out where appropriate.

Passive Voltage Probes

Passive probes are constructed of wires and connectors — and when needed for compensation or attenuation — also contain resistors and capacitors. There are no active components (transistors or amplifiers) in the probe’s signal path.

Because of their relative simplicity, passive probes tend to be the most rugged and economical of probes. They are easy to use and are also the most widely used type of probe.

Passive voltage probes are available with various attenuation factors – 1X, 10X, and 100X – for different voltage ranges. Of these, the 10X passive voltage probe is the most commonly used, and is the type of probe typically supplied as a standard accessory with oscilloscopes.

For applications where signal amplitudes are one-volt peak-to-peak or less, a 1X probe may be more appropriate, or even necessary. Where there’s a mix of low amplitude and moderate amplitude signals (tens of millivolts to tens of volts), a switchable 1X/10X probe can be a great convenience. It should be kept in mind, however, that a switchable 1X/10X probe is essentially two different probes in one. Not only are their attenuation factors different, but their bandwidth, rise time, and impedance (R and C) characteristics are different as well. As a result, these probes will not exactly match the oscilloscope’s input and will not provide the optimum performance achieved with a standard 10X probe.

Most passive probes are designed for use with general purpose oscilloscopes. As such, their bandwidths typically range from less than 100 MHz to 500 MHz or more.

A wide range of accessories are available for these probes,to facilitate connection to different wires, components or test points. See “Probe Accessories” and Figure 3.17 later in this chapter.

There is, however, a special category of passive probes that provide much higher bandwidths. They are referred to variously as 50 Ω probes, Zo probes, and voltage divider probes. These probes are designed for use in 50 Ω environments, which typically are high-speed device characterization, microwave communication, and time domain reflectometry (TDR). A typical 50 Ω probe for such applications has a bandwidth of several gigaHertz and a rise time of 100 picoseconds or faster.

Single Ended Active Voltage Probes

Active probes contain or rely on active components, such as transistors, for their operation. Most often, the active device is a field-effect transistor (FET).

The advantage of a FET input is that it provides a very low input capacitance, typically a few picoFarads (pF) down to less than 1 pF. Such ultra-low capacitance has several desirable effects.

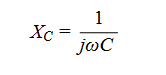

First, recall that a low value of capacitance, C, translates to a high value of capacitive reactance, Xc. This can be seen from the formula for Xc, which is:

Since capacitive reactance is the primary input impedance element of a probe, a low C results in a high input impedance over a broader band of frequencies. As a result, active FET probes will typically have specified bandwidths ranging from 500 MHz to several GHz

In addition to higher bandwidth, the high input impedance of active FET probes allows measurements at test points of unknown impedance with much less risk of loading effects. Also, longer ground leads can be used since the low capacitance reduces ground lead effects. The most important aspect, however, is that FET probes offer such low loading, that they can be used on high-impedance circuits that would be considerably loaded by passive probes.

With all of these positive benefits, including bandwidths as wide as DC to several GHz, you might wonder: Why bother with passive probes?

The answer is that active FET probes don’t have the voltage range of passive probes. The linear dynamic range of active probes is generally anywhere from ±0.6 V to ±10 V. In addition, the maximum voltage that they can withstand can be as low as ±40 V (DC + peak AC). In other words, you can’t measure from millivolts to tens of volts like you can with a passive probe. In addition, active probes can be damaged by inadvertently probing a higher voltage. They can even be damage by a static discharge.

Still, the high bandwidth of FET probes is a major benefit and their linear voltage range covers many typical semiconductor voltages. Thus, active FET probes are often used for low signal level applications, including fast logic families such as ECL, GaAs, and others.

Power Rail Probes

Traditional power integrity applications typically use passive or differential probes to measure power rails. With the changing technology landscape, designers need higher accuracy ripple measurements with very fast transitions pushing into multiple GHz range. New design challenges call for new probing techniques that can minimize noise from the measurement tools while also offering more bandwidth to see more signal content. A power rail probe is built for such a purpose and offers low loading for accuracy (especially in the most sensitive measurements) and offers low noise contribution and high bandwidth options. The higher bandwidth helps to see more signal content (harmonics, faster ripples, etc.) on DC rails that could affect data signals, and clocks.

An example of such a probe is shown in Figure 3.3.

The power rail probe covers power rail transient events up to several GHz and offers a large DC offset voltage range of 10s of volts to measure power supplies from plug, down to the pin of an integrated circuit. It also supports a wide dynamic range for power integrity applications, which, on higher voltage rails, lets the user look at droop on the line or when a lot of current is drawn by load or transients. The higher input impedance (50 kΩ at DC) in these probes minimize the oscilloscope loading effect on DC rails.

As the technology advances, power engineers are challenged to get more power efficiency from smaller and tighter designs. This is especially true for engineers in the automotive, industrial and consumer markets where typical validation requires probing at least one or more rails in parallel with other signals. This creates new constraints on connectivity due to tight spacing, buried signals, and smaller geometry components. The power rail probe comes with a modular and flexible connectivity options to cover most needs.

Differential Probes

Differential signals are signals that are referenced to each other instead of earth ground. Figure 3.4 illustrates several examples of such signals. These include the signal developed across a collector load resistor, high speed serial data signals, inverter output AC signals, multi-phase power systems, and numerous other situations where signals are in essence “floating” above ground. Some differential probes also come with ground cables. This isn’t necessary in all applications, but can help increase signal fidelity. If there is a lot of common mode noise, the ground cable

could be a better path for the noise to follow so it doesn’t pollute your measurements. Another reason to use this ground cable is for safety. When using differential probes, it is common that your test point could be floating hundreds of volts above ground. Adding a ground cable also protects against electrostatic discharge (ESD).

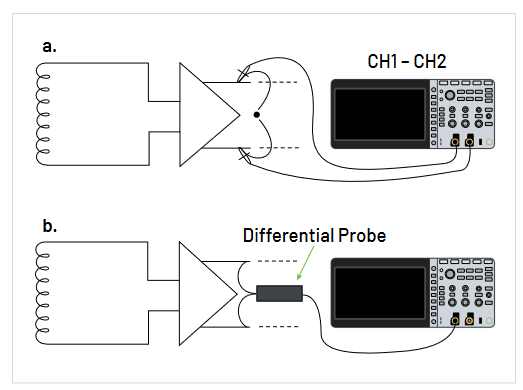

Differential signals can be probed and measured in two basic ways. Both approaches are illustrated in Figure 3.5.

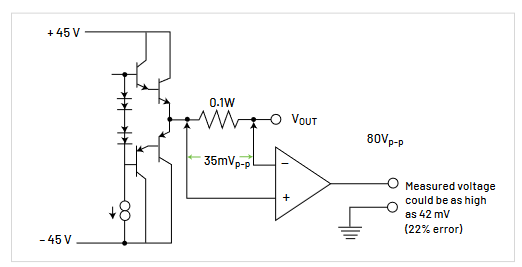

Using two probes to make two single-ended measurements, as shown in Figure 3.5a is a commonly used method. It’s also usually the least desirable method of making differential measurements. Nonetheless, the method is often used because a dual-channel oscilloscope is available with two probes. Measuring both signals to ground (single-ended) and using the oscilloscope’s math functions to subtract one from the other (channel A signal minus channel B) seems like an elegant solution to obtaining the difference signal, and it can be in situations where the signals are low frequency and have enough amplitude to be above any concerns of noise.

There are several potential problems with combining two single-ended measurements. One problem is that there are two long and separate signal paths down each probe and through each oscilloscope channel. Any delay differences between these paths results in time skewing of the two signals. On high-speed signals, this skew can result in significant amplitude and timing errors in the computed difference signal. To minimize this, matched probes should be used.

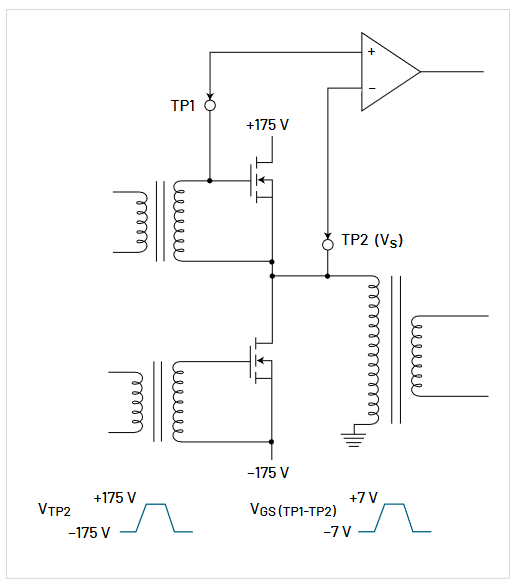

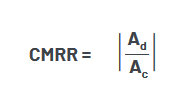

Another problem with single-ended measurements is that they don’t provide adequate common-mode noise rejection. Common-mode noise is noise that is impressed on both signal lines by such things as nearby clock lines or noise from external sources such as fluorescent lights. Many low-level signals, such as disk read channel signals, are transmitted and processed differentially in order to take advantage of common-mode noise rejection. In a differential system this common-mode noise tends to be subtracted out of the differential signal. The success with which this is done is referred to as the common-mode rejection ratio (CMRR).

Because of channel differences, the CMRR performance of single-ended measurements quickly declines to dismal levels with increasing frequency. This results in the signal appearing noisier than it actually would be if the commonmode rejection of the source had been maintained.

A differential probe, on the other hand, uses a differential amplifier to subtract the two signals, resulting in one differential signal for measurement by one channel of the oscilloscope (Figure 3.5b).

This provides substantially higher CMRR performance over a broader frequency range. Additionally, advances in circuit miniaturization have allowed differential amplifiers to be moved down into the actual probe head. In modern differential voltage probes, it is possible to achieve 60 dB (1000:1) or more of common mode rejection at 1 MHz and 30 dB (32:1) or more at 1 GHz. Optically isolated probes deliver even higher CMRR.

High-voltage Probes

The term “high voltage” is relative. What is considered high voltage in the semiconductor industry is practically nothing in the power industry. From the perspective of probes, however, we can define high voltage as being any voltage beyond what can be handled safely with a typical, generalpurpose 10X passive probe.

Typically, the maximum voltage for general-purpose passive probes is around 400 to 500 volts (DC + peak AC). Highvoltage probes on the other hand can have maximum ratings as high as 20,000 volts. An example of a high-voltage probe is shown in Figure 3.6.

Safety is a particularly important aspect of high-voltage probes and measurements. To accommodate this, many high-voltage probes have longer than normal cables. Typical cable lengths are 10 feet. This is usually adequate for locating the oscilloscope outside of a safety cage or behind a safety shroud. Options for 25-foot cables are also available for those cases where oscilloscope operation needs to be further removed from the high-voltage source.

Optically Isolated Probes

An isolated probe uses galvanic isolation to isolate the reference voltage of the probe from the reference voltage of the oscilloscope (typically earth ground). Because there is no electrical connection between the device under test and the oscilloscope, common mode currents have no path through the instrument, resulting in very high common mode rejection ratio, even at bandwidths of 500 MHz or 1 GHz.

While a high-quality, traditional differential probe would offer CMRR of –25dB at 100 MHz, an optically isolated probe can offer –120 dB. Isolation can also enable high differential voltage ranges into the kilovolt range.

Tektronix has developed a patented technology (called IsoVu) that uses optical isolation to provide best in class common mode rejection performance across a wide bandwidth. The IsoVu technology uses power-over-fiber and an optical analog signal path for complete galvanic isolation between the measurement system and the DUT. This technology is very useful, especially for making accurate voltage measurements on power converters that use fastswitching wide bandgap semiconductors.

A Tektronix IsoVu probe is shown in Figure 3.7.

Floating Measurements

Floating measurements are measurements that are made between two points, neither of which is at ground potential. If this sounds a lot like differential measurements described previously with regard to differential probes, you’re right. A floating measurement is a differential measurement, and, in fact, floating measurements can be made using differential probes.

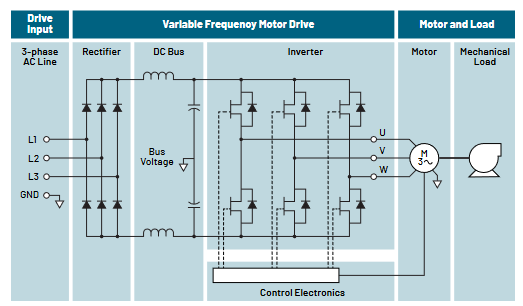

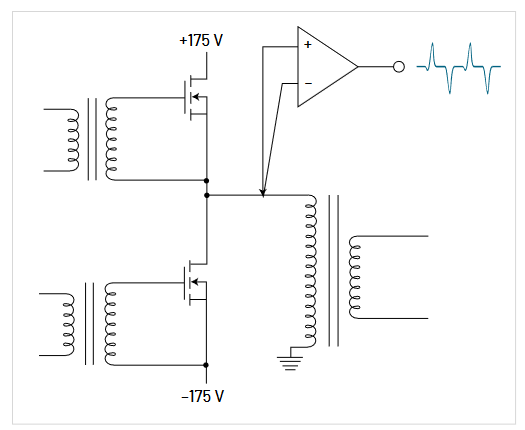

Generally, however, the term “floating measurement” is used in referring to power system measurements. Examples are switching supplies, motor drives, ballasts, and uninterruptible power sources where neither point of the measurement is at ground (earth potential). In addition, the signal “common” may be elevated (floating) to hundreds of volts from ground. Often, these measurements require rejection of high common-mode signals in order to evaluate low-level signals riding on them. Extraneous ground currents can also add hum to the display, causing even more measurement difficulty.

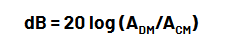

An example of a typical floating measurement situation is shown in Figure 3.8. In this motor drive system, the three phase AC line is rectified to a floating DC bus of up to 600 V. The ground-referenced control circuit generates pulse modulated gate drive signals through an isolated driver to the bridge transistors, causing each output to swing the full bus voltage at the pulse modulation frequency. Accurate measurement of the gate-to-source voltage requires rejection of the bus transitions. Additionally, the compact design of the motor drive, fast current transitions, and proximity to the rotating motor contribute to a harsh EMI environment.

Also, connecting the ground lead of an oscilloscope’s probe to any part of the motor drive circuit would cause a short to ground.

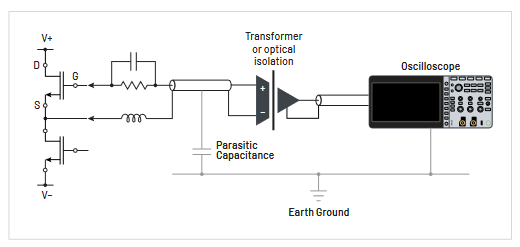

Rather than floating the oscilloscope, the probe isolator floats just the probe. This isolation of the probe can be done via either a transformer or optical coupling mechanism, as shown in Figure 3.9. In this case, the oscilloscope remains grounded, as it should, and the differential signal is applied to the tip and reference lead of the isolated probe. The isolator transmits the differential signal through the isolator to a receiver, which produces a ground-referenced signal that is proportional to the differential input signal. This makes the probe isolator compatible with virtually any instrument.

To meet different needs, various types of isolators are available. These include multi-channel isolators that provide two or more channels with independent reference leads. Also, fiber-optic based isolators are available for cases where the isolator needs to be physically separated from the instrument by long distances (e.g. 100 meters or more). As with differential probes, the key isolator selection criteria are bandwidth and CMRR. Additionally, maximum working voltage is a key specification for isolation systems.

Caution

To get around this direct short to ground, some oscilloscope users have used the unsafe practice of defeating the oscilloscope’s ground circuit. This allows the oscilloscope’s ground lead to float with the motor drive circuit so that differential measurements can be made. Unfortunately, this practice also allows the oscilloscope chassis to float at potentials that could be a dangerous or deadly shock hazard to the oscilloscope user.

Not only is “floating” the oscilloscope an unsafe practice, but the resulting measurements are often impaired by noise and other effects.

Current Probes

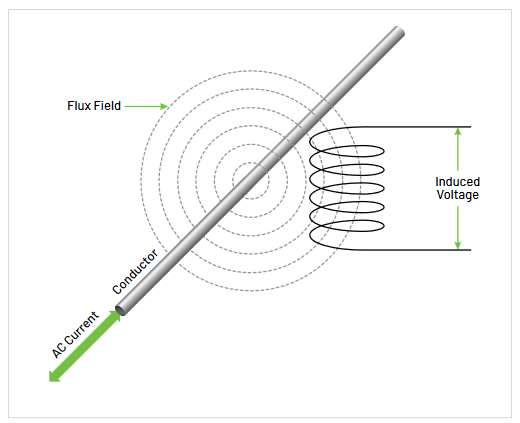

Current flow through a conductor causes an electromagnetic flux field to form around the conductor. Current probes are designed to sense the strength of this field and convert it to a corresponding voltage for measurement by an oscilloscope. This allows you to view and analyze current waveforms with an oscilloscope.

When used in combination with an oscilloscope’s voltage measurement capabilities, current probes also allow you to make a wide variety of power measurements. Depending on the waveform math capabilities of the oscilloscope, these measurements can include instantaneous power, true power, apparent power, and phase.

There are two types of current probes for oscilloscopes. AC current probes, which are usually passive probes, and AC/DC current probes, which are generally active probes. Both types use the same principle of transformer action for sensing alternating current (AC) in a conductor.

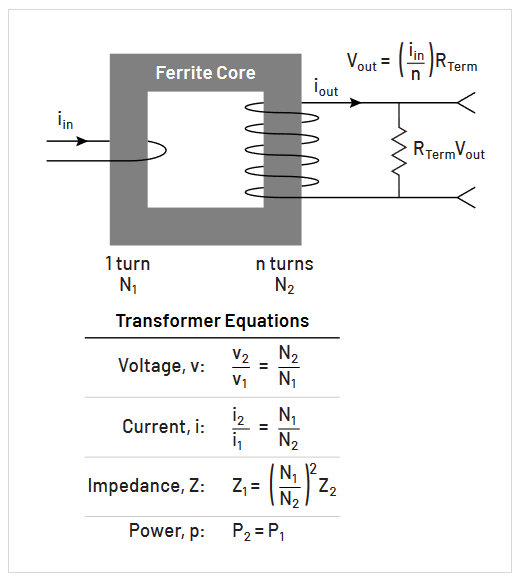

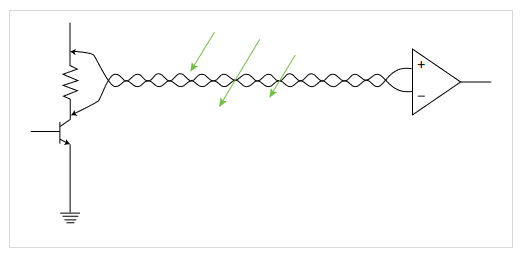

For transformer action, there must first be alternating current flow through a conductor. This alternating current causes a flux field to build and collapse according to the amplitude and direction of current flow. When a coil is placed in this field, as shown in Figure 3.10, the changing flux field induces a voltage across the coil through simple transformer action.

This transformer action is the basis for AC current probes. The AC current probe head is actually a coil that has been wound to precise specifications on a magnetic core. When this probe head is held within a specified orientation and proximity to an AC current carrying conductor, the probe outputs a linear voltage that is of known proportion to the current in the conductor. This current-related voltage can be displayed as a current-scaled waveform on an oscilloscope.

The bandwidth for AC current probes depends on the design of the probe’s coil and other factors. Bandwidths as high as a few GHz are possible. However, bandwidths under 100 MHz are more typical.

In all cases, there’s also a low-frequency cutoff for AC current probe bandwidth. This includes direct current (DC), since direct current doesn’t cause a changing flux field and, thus, cannot cause transformer action. Also at frequencies very close to DC, 0.01 Hz for example, the flux field still may not be changing fast enough for appreciable transformer action. Eventually, though, a low frequency is reached where the transformer action is sufficient to generate a measurable output within the bandwidth of the probe. Again, depending on the design of the probe’s coil, the lowfrequency end of the bandwidth might be as low as 0.5 Hz or as high as 1.2 kHz.

For probes with bandwidths that begin near DC, a Hall Effect device can be added to the probe design to detect DC. The result is an AC/DC probe with a bandwidth that starts at DC and extends to the specified upper frequency 3 dB point. This type of probe requires, at minimum, a power source for biasing the Hall Effect device used for DC sensing. Depending on the probe design, a current probe amplifier may also be required for combining and scaling the AC and DC levels to provide a single output waveform for viewing on an oscilloscope.

It’s important to keep in mind that a current probe operates in essence as a closely coupled transformer. This concept is illustrated in Figure 3.11, which includes the basic transformer equations. For standard operation, the sensed current conductor is a one-turn winding transformer (N1). The current from this single winding transforms to a multi-winding (N2) probe output voltage that is proportional to the turns ratio (N2/N1). At the same time, the probe’s impedance is transformed back to the conductor as a series insertion impedance. This insertion impedance is frequency dependent with its 1 MHz value typically being in the range of 30 to 500 mΩ, depending on the specific probe. The impedance appears in series within the circuit under test. For most cases, the small insertion impedance of a current probe imposes a negligible load.

Transformer basics can be taken advantage of to increase probe sensitivity by looping the conductor through the probe multiple times. Two loops doubles the sensitivity, and three loops triples the sensitivity. However, this also increases the insertion impedance by the square of the added turns.

Figure 3.12 illustrates a particular class of probe referred to as a split core probe. The windings of this type of probe are on a “U” shaped core that is completed with a ferrite slide that closes the top of the “U”. The advantage of this type of probe is that the ferrite slide can be retracted to allow the probe to be conveniently clipped onto the conductor whose current is to be measured. When the measurement is completed the slide can be retracted and the probe can be moved to another conductor.

Probes are also available with solid-core current transformers. These transformers completely encircle the conductor being measured. As a result, they must be installed by disconnecting the conductor to be measured, feeding the conductor through the transformer, and then reconnecting the conductor to its circuit. The chief advantages of solid-core probes is that they offer small size and very high frequency response for measuring very fast, low amplitude current pulses and AC signals.

Split-core current probes are by far the most common type. These are available in both AC and AC/DC versions, and there are various current-per-division display ranges, depending on the amp-second product.

The amp-second product defines the maximum limit for linear operation of any current probe. This product is defined for current pulses as the average current amplitude multiplied by the pulse width. When the amp-second product is exceeded, the core material of the probe’s coil goes into saturation. Since a saturated core cannot handle any more current-induced flux, there can no longer be constant proportionality between current input and voltage output.

The result is that waveform peaks are essentially “clipped off” in areas where the amp-second product is exceeded.

Core saturation can also be caused by high levels of direct current through the conductor being sensed. To combat core saturation and effectively extend the current measuring range, some active current probes provide a bucking current. The bucking current is set by sensing the current level in the conductor under test and then feeding an equal but opposite current back through the probe. Because opposing currents are subtractive, the bucking current can be adjusted to keep the core from going into saturation.

Because of the wide range of current measuring needs from milliamps to kiloamps, and from DC to high frequencies, there’s a correspondingly wide selection of current probes. Choosing a current probe for a particular application is similar in many respects to selecting voltage probes. Important selection criteria include:

- Current handling capability

- Ranges and sensitivities

- Insertion impedance

- Frequency range and derating

- Maximum amp-second product

- Connectivity

Logic Probes

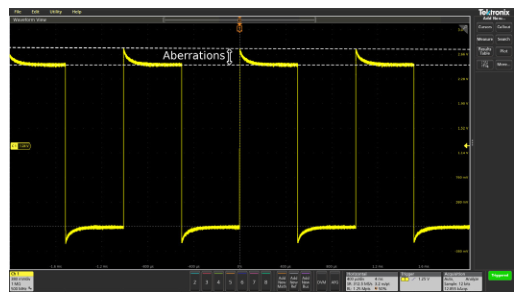

Faults in digital systems can occur for a variety of reasons. While a logic analyzer is the traditional tool for identifying and isolating fault occurrences, the actual cause of the logic fault is often due to the analog attributes of the digital waveform. Pulse width jitter, pulse amplitude aberrations, and regular old analog noise and crosstalk are but a few of the many possible analog causes of digital faults.

Analyzing the analog attributes of digital waveforms requires use of an oscilloscope. However, to isolate exact causes, digital designers often need to look at specific data pulses occurring during specific logic conditions. Logic triggering and timing analysis can be added to mixed signal oscilloscopes through the use of a digital probe.

The logic probe shown in Figure 3.13 offers an eightchannel pod. Each channel ends with a probe tip featuring a recessed ground for simplified connection to the deviceunder-test. The coax on the first channel is colored blue, making it easy to identify. The common ground is accessible on two 0.187 inch quick connect tabs, making it easy to create custom grounds for connecting to the device-undertest using widely-available quick connect receptacles. When connecting to square pins, you can use an adapter that attaches to the probe head extending the probe ground flush with the probe tip so you can attach to a header. These probes offer outstanding electrical characteristics with minimal capacitive loading.

Optical Probes

With the advent and spread of fiber-optic based communications, there’s a rapidly expanding need for viewing and analyzing optical waveforms. A variety of specialized optical system analyzers have been developed to fill the needs of communication system troubleshooting and analysis. However, there’s also an expanding need for general-purpose optical waveform measurement and analysis during optical component development and verification. Optical probes fill this need by allowing optical signals to be viewed on an oscilloscope.

The optical probe is an optical-to-electrical converter. On the optical side, the probe must be selected to match the specific optical connector and fiber type or optical mode of the device that’s being measured. On the electrical side, the standard probe-to-oscilloscope matching criteria are followed.

Other Probe Types

In addition to all of the above “fairly standard” probe types, there’s also a variety of specialty probes and probing systems. These include:

- Environmental probes, which are designed to operate over a very wide temperature range.

- Temperature probes, which are used to measure the temperature of components and other heat generating items.

- Probing stations and articulated arms (Figure 3.14) for probing fine-pitch devices such as multi-chip-modules, hybrid circuits, and ICs.

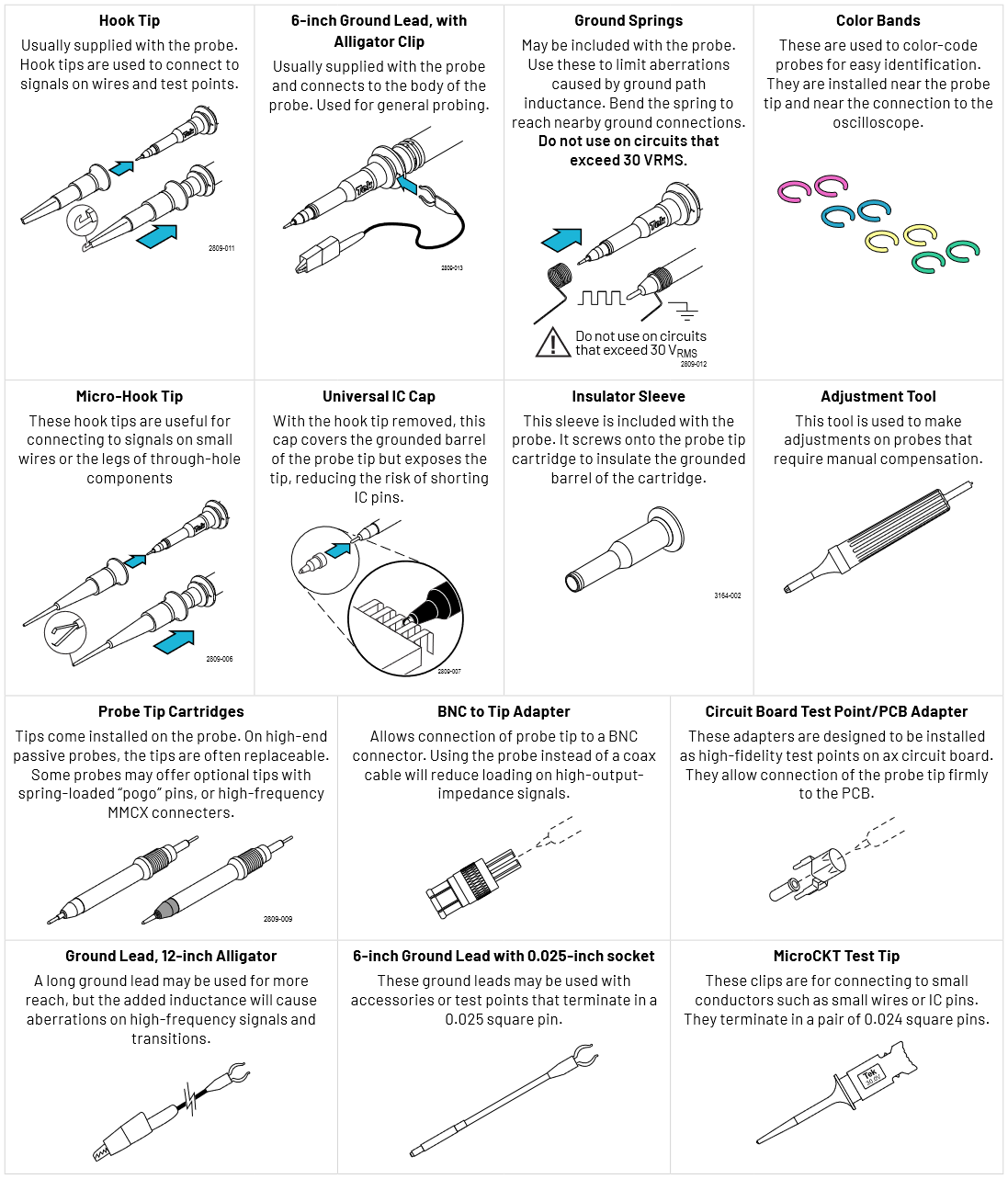

Probe Accessories

Most probes come with a package of standard accessories. These accessories often include a ground lead clip that attaches to the probe, and one or more probe tip accessories to aid in attaching the probe to various test points. Probes will often come with a probe compensation tool; however, some modern probes don’t require compensation by hand, and instead implement automatic digital compensation. Figure 3.15 shows an example of a typical general purpose voltage probe and its standard accessories.

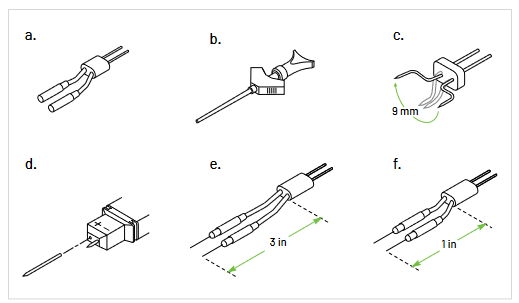

Probes that are designed for specific application areas, such as probing surface mount devices, may include additional probe tip adapters in their standard accessories package. Also, various special purpose accessories may be available as options for the probe. Figure 3.16 illustrates several types of probe tip adaptors designed for use with small geometry probes.

It’s important to realize that most probe accessories, especially probe tip adaptors, are designed to work with specific probe models. Switching adaptors between probe models or probe manufacturers is not recommended since it can result in poor connection to the test point or damage to either the probe or probe adaptor.

When selecting probes for purchase, it’s also important to take into account the type of circuitry that you’ll be probing and any adaptors or accessories that will make probing quicker and easier. In many cases, less expensive commodity probes don’t provide a selection of adaptor options. On the other hand, probes obtained through an oscilloscope manufacturer often have an extremely broad selection of accessories for adapting the probe to special needs. An example of this is shown in Figure 3.17, which illustrates the variety of accessories and options available for a particular class of probes. These accessories and options will, of course, vary between different probe classes and models.

4. A Guide to Probe Selection

The preceding chapters have covered a wide range of topics regarding oscilloscope probes in terms of how probes function, the various types of probes, and their effects on measurements. For the most part, the focus has been on what happens when you connect a probe to a test point.

In this chapter, the focus changes to the signal source and how to translate its properties into criteria for appropriate probe selection.

The goal, as always, is to select the probe that delivers the best representation of the signal to the oscilloscope. However, it doesn’t stop there. The oscilloscope imposes certain requirements that must also be considered as part of the probe selection process.

This chapter explores the various selection requirements, beginning with understanding the requirements imposed by the signal source.

Choosing the Right Probe

Because of the wide range of oscilloscope measurement applications and needs, there’s also a broad selection of oscilloscope probes on the market. This can make probe selection a confusing process.

To cut through much of the confusion and narrow the selection process, always follow the oscilloscope manufacturer’s recommendations for probes. This is important because different oscilloscopes are designed for different bandwidth, rise time, sensitivity, and input impedance considerations. Taking full advantage of the oscilloscope’s measurement capabilities requires a probe that matches the oscilloscope’s design considerations.

Additionally, the probe selection process should include consideration of your measurement needs. What are you trying to measure? Voltages? Current? An optical signal? By selecting a probe that is appropriate to your signal type, you can get direct measurement results faster.

Also, consider the amplitudes of the signals you are measuring. Are they within the dynamic range of your oscilloscope? If not, you’ll need to select a probe that can adjust dynamic range. Generally, this will be through attenuation with a 10X or higher probe.

Make sure that the bandwidth, or rise time, at the probe tip exceeds the signal frequencies or rise times that you plan to measure. Always keep in mind that non-sinusoidal signals have important frequency components or harmonics that extend well above the fundamental frequency of the signal. For example, to fully include the 5th harmonic of a 100 MHz square wave, you need a measurement system with a bandwidth of 500 MHz at the probe tip. Similarly, your oscilloscope system’s rise time should be three to five times faster than the signal rise times that you plan to measure.

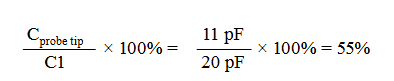

In addition, always take into account possible signal loading by the probe. Look for high-resistance, low-capacitance probes. For most applications, a 10 MΩ probe with 20 pF or less capacitance should provide ample insurance against signal source loading. However, for some high-speed digital circuits you may need to move to the lower tip capacitance offered by active probes.

Finally, keep in mind that you must be able to attach the probe to the circuit before you can make a measurement. This may require special selection considerations about probe head size and probe tip adaptors to allow for easy and convenient circuit attachment.

Visit www.tek.com/probe-selector to find the recommended Tektronix probe for your testing needs.

Understanding the Signal Source

There are four fundamental signal source issues to be considered in selecting a probe. These are the signal type, the signal frequency content, the source impedance, and the physical attributes of the test point. Each of these issues is covered in the following discussion.

Signal Type

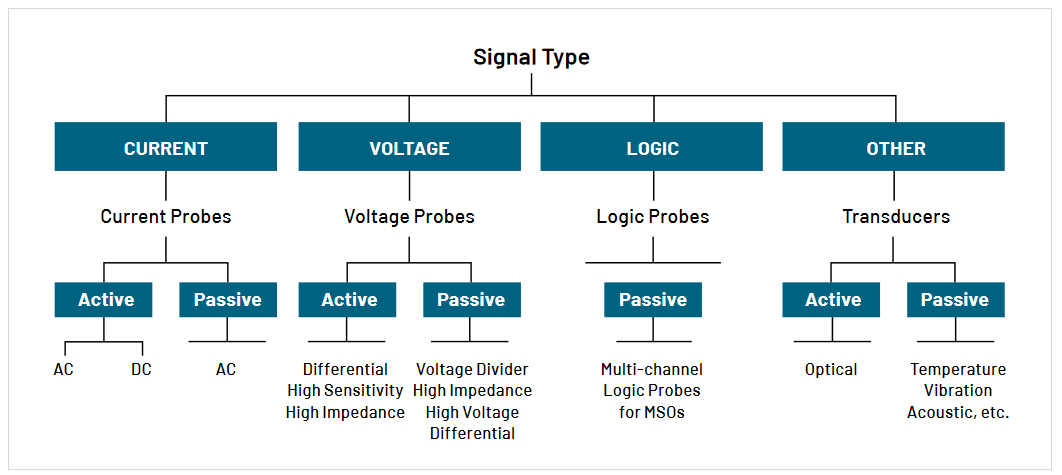

The first step in probe selection is to assess the type of signal to be probed. For this purpose, signals can be categorized as being one of the following:

- Voltage Signals

- Current Signals

- Logic Signals

- Other Signals

Voltage signals are the most commonly encountered signal type in electronic measurements. As such, voltage sensing probes are the most common type of oscilloscope probe. It should also be noted that since oscilloscopes require a voltage signal at their input, other types of oscilloscope probes are, in essence, transducers that convert the sensed phenomenon to a corresponding voltage signal. A common example of this is the current probe, which transforms a current signal into a voltage signal for viewing on an oscilloscope.

Logic signals are actually a special category of voltage signals. Logic probes for mixed signal oscilloscopes (MSOs) determine logic levels by comparing the input signals to adjustable voltage thresholds. The resulting high and low levels can be displayed on the MSO, and may also be used for triggering on specific binary combinations.

In addition to voltage, current, and logic signals, there are numerous other types of signals that may be of interest. These can include signals from optical, mechanical, thermal, acoustic, and other sources. Various transducers can be used to convert such signals to corresponding voltage signals for oscilloscope display and measurement.

Figure 4.1 provides a graphical categorization of probes based on the type of signal to be measured. Notice that under each category there are various probe subcategories that are further determined by additional signal attributes as well as oscilloscope requirements.

Signal Frequency Content

All signals, regardless of their type, have frequency content. DC signals have a frequency of 0 Hz, and pure sinusoids have a single frequency — that is the reciprocal of the sinusoid’s period. All other signals contain multiple frequencies whose values depend upon the signals waveshape. For example, a symmetrical square wave has a fundamental frequency (fo) that’s the reciprocal of the square wave’s period and additional harmonic frequencies that are odd multiples of the fundamental (3fo, 5fo, 7fo, ...). The fundamental is the foundation of the waveshape, and the harmonics combine with the fundamental to add structural detail such as the waveshape’s transitions and corners.

For a probe to convey a signal to an oscilloscope while maintaining adequate signal fidelity, the probe must have enough bandwidth to pass the signal’s major frequency components with minimum disturbance. In the case of square waves and other periodic signals, this generally means that the probe bandwidth needs to be three to five times higher than the signal’s fundamental frequency. This allows the fundamental and the first few harmonics to be passed without undue attenuation of their relative amplitudes. The higher harmonics will also be passed, but with increasing amounts of attenuation since these higher harmonics are beyond the probe’s 3-dB bandwidth point. However, since the higher harmonics are still present at least to some degree, they’re still able to contribute somewhat to the waveform’s structure.

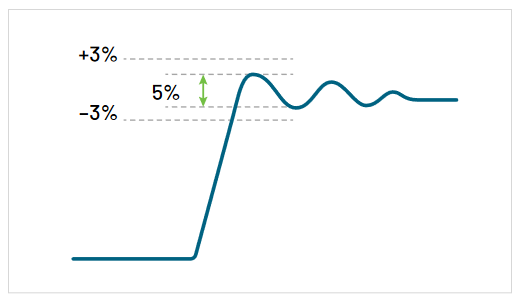

The primary effect of bandwidth limiting is to reduce signal amplitude. The closer a signal’s fundamental frequency is to the probe’s 3-dB bandwidth, the lower the overall signal amplitude seen at the probe output. At the 3-dB point, amplitude is down 30%. Also, those harmonics or other frequency components of a signal that extend beyond the probe’s bandwidth will experience a higher degree of attenuation because of the bandwidth roll-off. The result of higher attenuation on higher frequency components may be seen as a rounding of sharp corners and a slowing of fast waveform transitions (see Figure 4.2).

It should also be noted that probe tip capacitance can also limit signal transition rise times. However, this has to do with signal source impedance and signal source loading, which are the next topics of discussion.

Signal Source Impedance

The discussion of source impedance can be distilled down to the following key points:

- The probe’s impedance combines with the signal source impedance to create a new signal load impedance that has some effect on signal amplitude and signal rise times.

- When the probe impedance is substantially greater than the signal source impedance, the effect of the probe on signal amplitude is negligible.

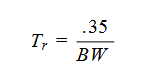

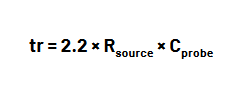

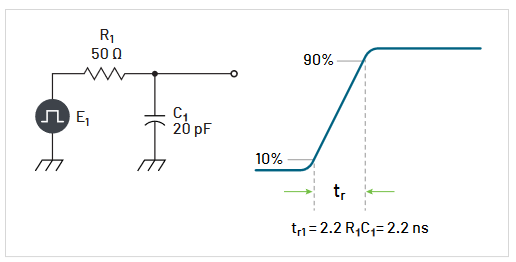

- Probe tip capacitance, also referred to as input capacitance, has the effect of stretching a signal’s rise time. This is due to the time required to charge the input capacitance of the probe from the 10% to 90% level, which is given by:

The RC integration network always produces a 10 to 90%rise time of 2.2RC. This is derived from the universal timeconstant curve of a capacitor. The value of 2.2 is the number of RC time constants necessary for C to charge through R from the 10% value to the 90% amplitude value of the pulse.

From the above points, it’s clear that high-impedance, low-capacitance probes are the best choice for minimizing probe loading of the signal source. Also, probe loading effects can be further minimized by selecting lowimpedance signal test points whenever possible. Refer to the section titled “Different Probes for Different Needs” for more detail regarding signal source impedance and the effects of its interaction with probe impedance.

Physical Connection Considerations

The location and geometry of signal test points can also be a key consideration in probe selection. Is it enough to just touch the probe to the test point and observe the signal on the oscilloscope? Or will it be necessary to leave the probe attached to the test point for signal monitoring while making various circuit adjustments? For the former situation, a needle-style probe tip is appropriate, while the latter situation requires some kind of retractable hook tip.

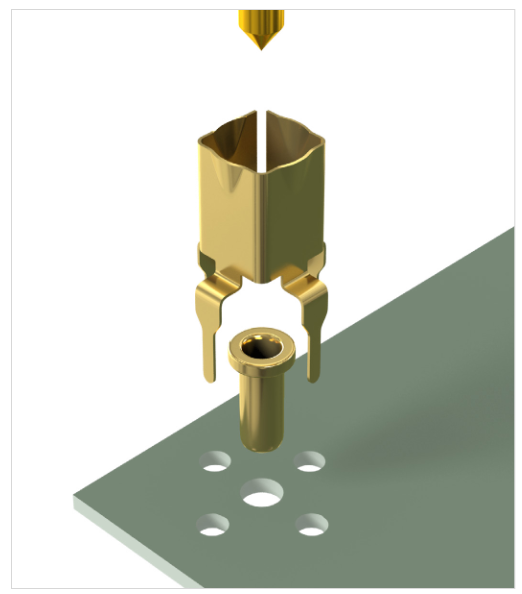

The size of the test point can also impact probe selection. Standard size probes and accessories are fine for probing connector pins, resistor leads, and back planes. However,for probing surface mount circuitry, smaller probes with accessories designed for surface mount applications are recommended.

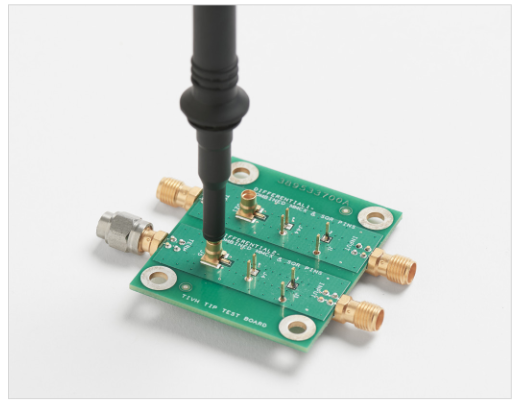

Newer probes may be available with MMCX connectors. These connectors may be soldered onto circuit boards as either temporary or permanent test points. They can help maintain high signal fidelity by minimizing ground lead length and bringing shielding right to the device under test. Figure 4.3. shows how probes with MMCX connectors can be applied.

The goal is to select probe sizes, geometries, and accessories that best fit your particular application. This allows quick, easy, and solid connection of probes to test points for reliable measurements.

Understanding the Oscilloscope

Oscilloscope issues have as much bearing on probe selection as signal source issues. If the probe doesn’t match the oscilloscope, signal fidelity will be impaired at the oscilloscope end of the probe.

Bandwidth and Rise Time

It’s important to realize that the oscilloscope and its probes act together as a measurement system. Thus, the oscilloscope used should have bandwidth and rise time specifications that equal or exceed those of the probe used and that are adequate for the signals to be examined.

In general, the bandwidth and rise time interactions between probes and oscilloscopes are complex. Because of this complexity, most oscilloscope manufacturers specify oscilloscope bandwidth and rise time to the probe tip for specific probe models designed for use with specific oscilloscopes. To ensure adequate oscilloscope system bandwidth and rise time for the signals that you plan to examine, it’s best to follow the oscilloscope manufacturer’s probe recommendations.

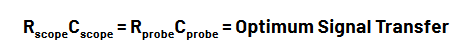

Input Resistance and Capacitance

All oscilloscopes have input resistance and input capacitance. For maximum signal transfer the input R and C of the oscilloscope must match the R and C presented by the probe’s output as follows:

More specifically, 50 Ω oscilloscope inputs require 50 Ω probes, and 1 MΩ oscilloscope inputs require 1 MΩ probes. A 1 MΩ oscilloscope can also be used with a 50 Ω probe when the appropriate 50 Ω adapter is used.

Probe-to-oscilloscope capacitances must be matched as well. This is done through selection of probes designed for use with specific oscilloscope models. Additionally, many probes have a compensation adjustment to allow precise matching by compensating for minor capacitance variations. Whenever a probe is attached to an oscilloscope, the first thing that should be done is to adjust the probe’s compensation. Failing to properly match a probe to the oscilloscope – both through proper probe selection and proper compensation adjustment – can result in significant measurement errors.

Sensitivity

The oscilloscope’s vertical sensitivity range determines the overall dynamic range for signal amplitude measurement. For example, an oscilloscope with a 10-division vertical display range and a sensitivity range from 1 mV/division to 10 V/division has a practical vertical dynamic range from around 0.1 mV to 100 V. If the various signals that you intend to measure range in amplitude from 0.05 mV to 150 V, the base dynamic range of the example oscilloscope falls short at both the low and high ends. However, this shortcoming can be remedied by appropriate probe selection for the various signals that you’ll be dealing with.