Contact us

Call us at

Available 6:00 AM – 5:00 PM (PST) Business Days

Download

Download Manuals, Datasheets, Software and more:

Feedback

Utilize Clean Hydrogen to Harness the Power of Chemistry

One fuel cell type at the cornerstone of modern clean energy solutions is hydrogen fuel cells. They convert chemical energy from fuels into electrical energy through electrochemical reactions. Unlike conventional combustion-based power generation, fuel cells produce electricity with higher efficiency and significantly lower emissions, making them vital for sustainable energy systems.

However, much like traditional power sources, fuel cell systems require extensive testing to ensure that they deliver the cell performance, durability, and longevity necessary for the intended use case. By creating a rigorous testing program, you can ensure that your designs meet regulatory standards while also optimizing product quality.

Techniques for Developing Fuel Cells

Test Full Fuel Cell Stacks

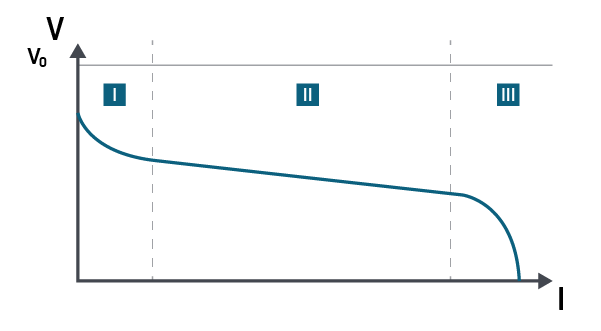

The fuel cell market is currently experiencing enormous growth, as high as 30%, brought about by factors such as government initiatives, economic incentives, and new applications. In areas like industrial trucks, delivery vehicles, long-distance trucks, and emergency power generators, hydrogen fuel cells bring attractive benefits in operating cost, efficiency, and carbon offsets. The importance of ensuring flexibility while maintaining lower operating costs has increased exponentially throughout the industry. A common indication of cell performance is the polarization and power density curves of the fuel cell stack. These curves are usually assessed under the optimal operating conditions (temperature, humidity, electrocatalysis, and ion-exchange membrane) of a fuel cell stack.

By programming DC electronic loads like the EA ELR 10000 Series in different current or resistance profiles, these measurements can easily be obtained. These Electronic loads are ideal for fuel cell testing with input power up to 30kW, that can be expanded in a system up to 3.84MW. A built-in arbitrary waveform generator allows dynamic testing, while the regenerative capabilities capture up to 96% of the energy from the fuel cells that would otherwise be lost as heat.

Aging Fuel Cells for Durability

It is always necessary to perform the durability test on fuel cells to ensure product safety and stability; the fuel cell is often the active energy source in applications. The durability test for a fuel cell can be a long process that can lead to a very large operating cost for a typical 100kW fuel cell stack system. The automotive standard requires 5,000 hours (~7 months) and stationary storage applications require more than 10,000 hours. Even by utilizing step and triangular potential cycles to shorten the long durability test time, there can be substantial energy loss over the course of the testing.

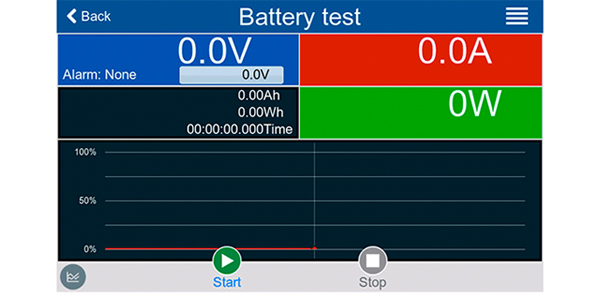

Regenerative electronic loads with built-in function generators like the EA ELR 10000 Series are ideal for these situations. Regenerative technology captures up to 96% of that sunk energy during cycling that would otherwise be lost to heat. A built-in function generator allows accelerated test profiles (like step or triangular waveforms) while allowing accumulated energy measurements to be obtained through a discharging test function.

I: Cell exhibits non-linear voltage drop with increasing current. II: Ohmic resistance dominates with linear V/I relationship. III: Voltage drops exponentially as the chemical reaction can no longer supply new energy.

Learn More:

Simulate Fuel Cells

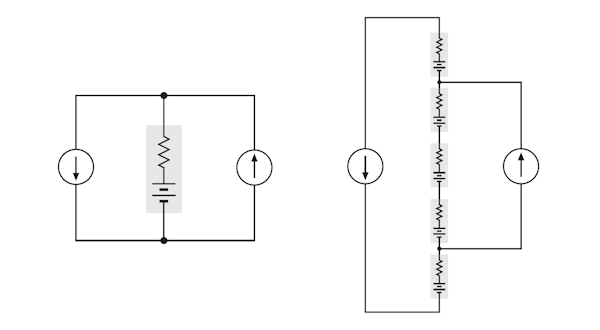

When working with fuel cell technology, it’s inevitable that the reliability of these electrochemical systems comes into play. The ability to simulate fuel cell stacks when working with the rest of the energy system can reduce development time and improve reliability of the overall system.

EA PSI 10000 Series power supplies include the ability to operate of a UI (or Voltage-Current) table that changes the output voltage as the measured current changes. This allows the simulation of a fuel cell output modeling the polarization curve.

EA Bidirectional supplies bring the capability to both simulate fuel cell output and regeneratively sink power from fuel cell output. This allows a single instrument or rack of equipment to perform double-duty for systems from 30kW up to 3.84MW.

Understand Single Cell Measurements

Anyone involved in the design, manufacture, application or repair of fuel cells, or fuel cell powered devices, needs cell data that is available only through direct electrical measurements. When properly interpreted, this data not only provides an understanding of how and why fuel cells work, but also indicates the health of operational cells, helps predict their life, reveals failure mechanisms, and provides insight into their suitability for specific applications.

Instruments like the Keithley 6221 AC+DC Current Source, 2182A Nanovoltmeter, and 2450 Source Measure Unit are invaluable tools to performing the precise electrical characterization of individual fuel cells necessary to understand the electrochemical processes at play.