Contact us

Call us at

Available 6:00 AM – 5:00 PM (PST) Business Days

Download

Download Manuals, Datasheets, Software and more:

Feedback

Improving Performance of Power Management Devices

Diverse, custom applications can be engineered using power management devices, including power management ICs, power management units, battery management units, and DC-DC converters, used in application including EVs, smart homes and devices, motor controls, power-loss protection devices, and more. Design Engineers continue to investigate how their devices can improve power efficiency over wide voltages and environmental operating conditions.

Accelerating Power Management Device Testing

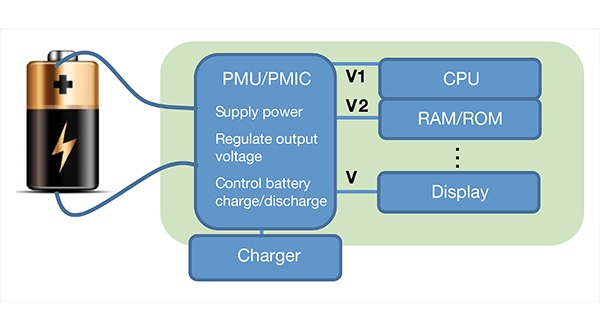

PMIC/PMU is the key battery management component in battery-powered devices.

Learn More:

Test PMICs and PMUs

Designing and evaluating the power management IC (PMIC) or power management unit (PMU) are very important steps in the product development process. The PMIC/PMU is the module in an electronic device that manages the battery. Assessing a PMIC/PMU is essential to ensure that the product works correctly when the battery is in different states of charge, various amp-hour capacity levels, and at different battery impedances, and to ensure that its charge/discharge function works properly and will not damage the battery by over-charging or over-discharging.

Ensure The Highest Power Integrity

Characterizing PMICs, PMUs, and battery management units (BMU) for power integrity, power efficiency, signal integrity, common mode noise, and multi-rail management ensures that devices operate as designed and are well optimized. Tek’s power integrity analysis solution, enabled by either the 5 or 6 Series B MSO, includes probes and analysis tools you need to accelerate time to validation.

- Validate power supply sequencing

- Find sources of power rail ripple

- Correlate voltage, current and digital signals

Software tools for oscilloscopes accelerated power integrity validation.

Learn More:

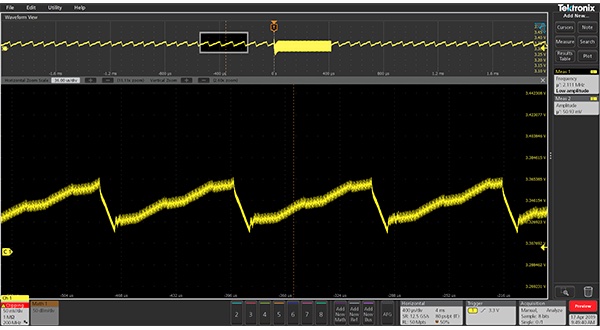

Leverage the capabilities of Power Rail probes to analyze additional high frequency noise overlaid on the ripple.

Learn More:

Measuring Ripple and Noise on Power Rails

Validating Power Rail Performance

Power integrity, signal integrity analysis, power rail and ripple measurements play a critical role especially with highly integrated system on chip and microprocessor designs in which multiple technologies interface together. It is important to look at each DC line to see if the power supplied is within the tolerance band of a target system or device. The typical applications can be found across industries that need power conversion and have multiple DC voltage levels in the circuit design.

Test DC-DC Converters

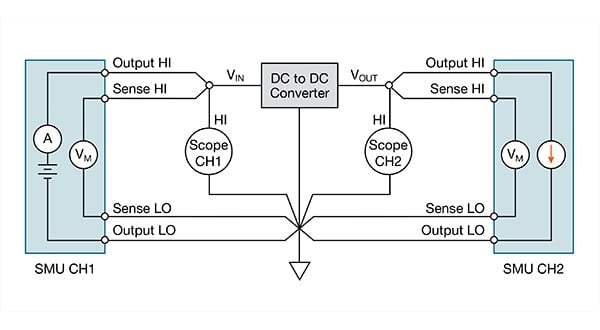

Given the increased pressure to develop products that consume less power and have longer battery life, design engineers need to achieve higher power conversion efficiencies. As a result, numerous measurements are required to characterize the electrical parameters of DC- DC converters. The tests performed include line regulation, load regulation, input and output voltage accuracy, quiescent current, efficiency, turn-on time, ripple, and transient response. Some of these tests require DC test instruments for sourcing and measuring; others require an oscilloscope, and some may require both.

Testing a non-isolated DC-DC converter using both a scope and two SMUs.

Learn More: