Contact us

Call us at

Available 9 AM - 5 PM IST Business Days

Download

Download Manuals, Datasheets, Software and more:

Feedback

2450 Source Measure Unit (SMU) Instrument Datasheet

More Information

- 2400 Graphical Series SMU

- Product Support

- Explore more Software models

Read Online:

The 2450 is Keithley's next-generation SourceMeter source measure unit (SMU) instrument that truly brings Ohm's law (current, voltage, and resistance) testing right to your fingertips. Its innovative graphical user interface (GUI) and advanced, capacitive touchscreen technology allow intuitive usage and minimize the learning curve to enable engineers and scientists to learn faster, work smarter, and invent easier. The 2450 is the SMU for everyone: a versatile instrument, particularly well-suited for characterizing modern scaled semiconductors, nano-scale devices and materials, organic semiconductors, printed electronics, and other small-geometry and low-power devices. All this combined with Keithley SMU precision and accuracy allows users to Touch, Test, Invent® with the new favorite go-to instrument in the lab for years to come.

Key Features

- Capabilities of analyzers, curve tracers, and I-V systems at a fraction of their cost

- Five-inch, high resolution capacitive touchscreen GUI

- 0.012% basic measure accuracy with 6½-digit resolution

- Enhanced sensitivity with new 20mV and 10nA source/measure ranges

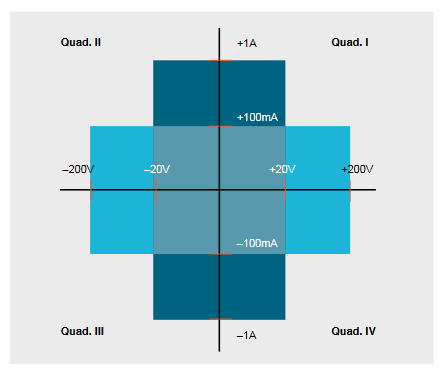

- Source and sink (four-quadrant) operation

- Four "Quickset" modes for fast setup and measurements

- Built-in, context-sensitive front panel help

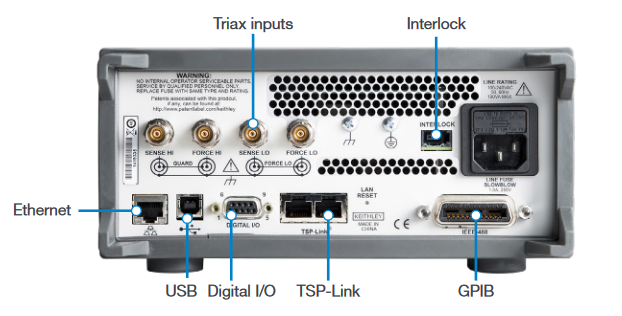

- Front panel input banana jacks; rear panel input triaxial connections

- 2450 SCPI and TSP® scripting programming modes

- 2400 SCPI-compatible programming mode

- Front panel USB memory port for storing data, programming, instrument configurations, and to upgrade the unit

Learn Faster, Work Smarter, and Invent Easier

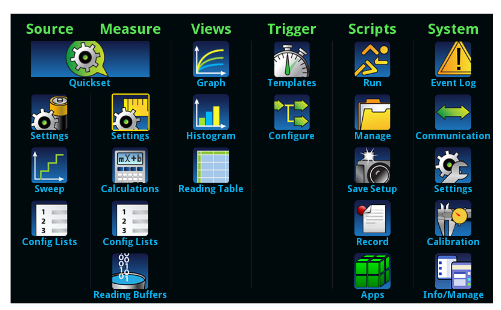

Unlike conventional instruments with dedicated pushbutton technology and small, obscure, limited-character displays, the 2450 features a five-inch, full-color, highresolution touchscreen that facilitates ease of use, learning, and optimizes overall speed and productivity. A simple icon-based menu structure reduces configuration steps by as much as 50 percent and eliminates the cumbersome multi-layer menu structures typically used on soft-key instruments. Built-in, context-sensitive help enables intuitive operation and minimizes the need to review a separate manual. These capabilities combined with its application versatility make the 2450 the SMU instrument inherently easy to use for basic and advanced measurement applications, regardless of your experience level with SMU instruments.

Fourth-Generation, All-in-One SMU Instrument

The 2450 is the fourth-generation member of Keithley's award-winning SourceMeter family of SMU instruments and leverages the proven capabilities of the 2400 SourceMeter SMU Instrument. It offers a highly flexible, four-quadrant voltage and current sourwce/load coupled with precision voltage and current meters. This all-in-one instrument gives you the capabilities of a:

- Precision power supply with V and I readback

- True current source

- Digital multimeter (DCV, DCI, ohms, and power with 6½-digit resolution)

- Precision electronic load

- Trigger controller

Comparison Table: 2400 vs 2450

| Model 2400 | Model 2450 |

| V-Ranges: 200 mV – 200 V | V-Ranges: 20 mV – 200 V |

| I-Ranges: 1 μA – 1 A | I-Ranges: 10 nA – 1 A |

| 0.012% Basic Accuracy | 0.012% Basic Accuracy |

| Wideband Noise: 4 mVrms Typ. | Wideband Noise: 2 mVrms Typ. |

| Sweep Types: Linear, Log, Custom, Source-Memory | Sweep Types: Linear, Log, Dual Linear, Dual Log, Custom, Source-Memory (SCPI 2400 Mode) |

| 5000 Point Reading Buffer | >250,000 Point Reading Buffer |

| >2000 Readings/Second | >3000 Readings/Second |

| SCPI Programming | SCPI (2400 + 2450) + TSP Programming |

| GPIB | GPIB, USB, Ethernet (LXI) |

| Front/Rear Banana Jacks | Front: Banana Jacks, Rear: Triax |

Ease of Use Beyond the Touchscreen

In addition to its five-inch, color touchscreen, the 2450 front panel has many features that supplement its speed, userfriendliness, and learnability, including a USB 2.0 memory I/O port, a HELP key, a rotary navigation/control knob, a front/ rear input selector button, and banana jacks for basic bench applications. The USB 2.0 memory port supports easy data storing, saving instrument configurations, loading test scripts, and system upgrades. Plus, all front panel buttons are backlit to enhance visibility in low-light environments.

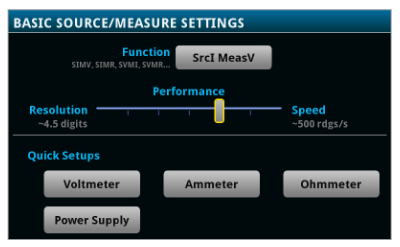

Four "Quickset" modes simplify user setup. With one touch, the instrument can be quickly configured for various operating modes without the need to configure the instrument indirectly for this operation.

Quickset modes enable fast setup and time to measurements.

Comprehensive Built-in Connectivity

Rear panel access to rear-input triax connectors, remote control interfaces (GPIB, USB 2.0, and LXI/Ethernet), D-sub 9-pin digital I/O port (for internal/external trigger signals and handler control), instrument interlock control, and TSP-Link® jacks enables easy configuration of multiple instrument test solutions and eliminates the need to invest in additional adapter accessories.

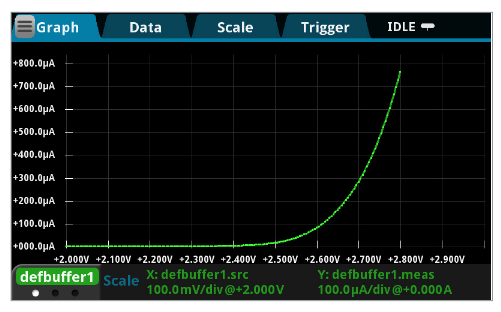

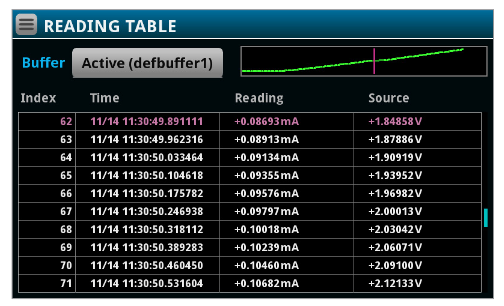

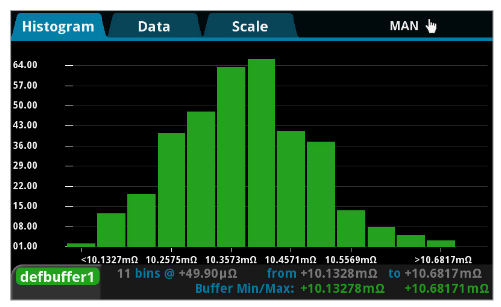

Convert Raw Data to Information

The 2450 provides a full plotting and sheet view to display sweeps, measurement data, and charting right on the screen. It also supports exporting to a spreadsheet for further analysis, dramatically improving productivity for research, bench-top testing, device qualification, and debugging.

Full data display, charting, and export to a spreadsheet lets you convert raw data to useful information.

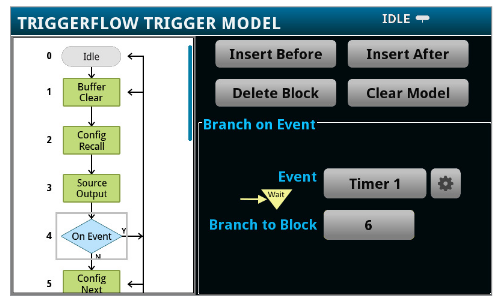

TriggerFlow® Building Blocks for Instrument Control and Execution

The 2450 incorporates Keithley's new TriggerFlow triggering system that allows user control of instrument execution. Similar to developing a flow chart, TriggerFlow diagrams are created using four fundamental building blocks:

- Wait – Waits for an event to occur before the flow continues

- Branch – Branches when a condition has been satisfied

- Action – Initiates an action in the instrument, for example, measure, source, delay, set digital I/O, etc.

- Notify – Notifies other equipment that an event has occurred

A TriggerFlow model using a combination of these building blocks can be created from the front panel or by sending remote commands. With the TriggerFlow system, users can build triggering models from very simple to complex with up to 63 block levels. The 2450 also includes basic triggering functions, including immediate, timer, and manual triggering.

Unmatched System Integration and Programming Flexibility

When the 2450 is integrated as part of a multi-channel I-V test system, the Test Script Processor (TSP®) embedded scripting capability allows test scripts to be run by the instrument, enabling the user to create powerful measurement applications with significantly reduced development times. TSP technology also offers channel expansion without a mainframe. Keithley's TSPLink® channel expansion bus, which uses a 100 Base T Ethernet cable, connects multiple 2450 instruments and other TSP instruments such as Keithley's Series 2600B SourceMeter SMU instruments and Series 3700A Switch/ Multimeter systems in a master-subordinate configuration that behaves as one integrated system. The TSP-Link expansion bus supports up to 32 units per GPIB or IP address, making it easy to scale a system to fit an application's particular requirements.

The 2450 also includes a SCPI programming mode that optimizes the instrument's new features, as well as a SCPI 2400 mode that provides backwards compatibility with the existing 2400 SourceMeter instrument. Not only does this preserve your 2400 investment but it also eliminates re-work normally associated with upgrading to a new instrument with new capabilities.

Parallel Test Capability

With the TSP technology in the 2450, multiple devices can be tested in parallel to meet the needs of device research, advanced semiconductor lab applications, and even high throughput production test. This parallel testing capability enables each instrument in the system to run its own complete test sequence, creating a fully multi-threaded test environment. The number of tests that can be run in parallel on a 2450 can be as high as the number of instruments in the system.

Typical Applications

Ideal for current/voltage characterization and functional test of a wide range of today's modern electronics and devices, including:

- Nanomaterials and Devices

- – Graphene

- – Carbon nanotubes

- – Nanowires

- – Low power nanostructures

- Semiconductor Structures

- – Wafers

- – Thin films

- Organic Materials and Devices

- – E-inks

- – Printable electronics

- Energy Efficiency and Lighting

- – LEDs/AMOLEDs

- – Photovoltaics/Solar cells

- – Batteries

- Discrete and Passive Components

- – Two-leaded: Resistors, diodes, zener diodes, LEDs, disk drive heads, sensors

- – Three-leaded: Small signal bipolar junction transistors (BJTs), field effect transistors (FETs), and more

- Material Characterization

- – Resistivity

- – Hall Effect

- – High ohmic resistance (using triax connectors)

- Electrochemistry

- – Cyclic voltammetry

- – Battery charge/discharge cycling

- – Electro-deposition

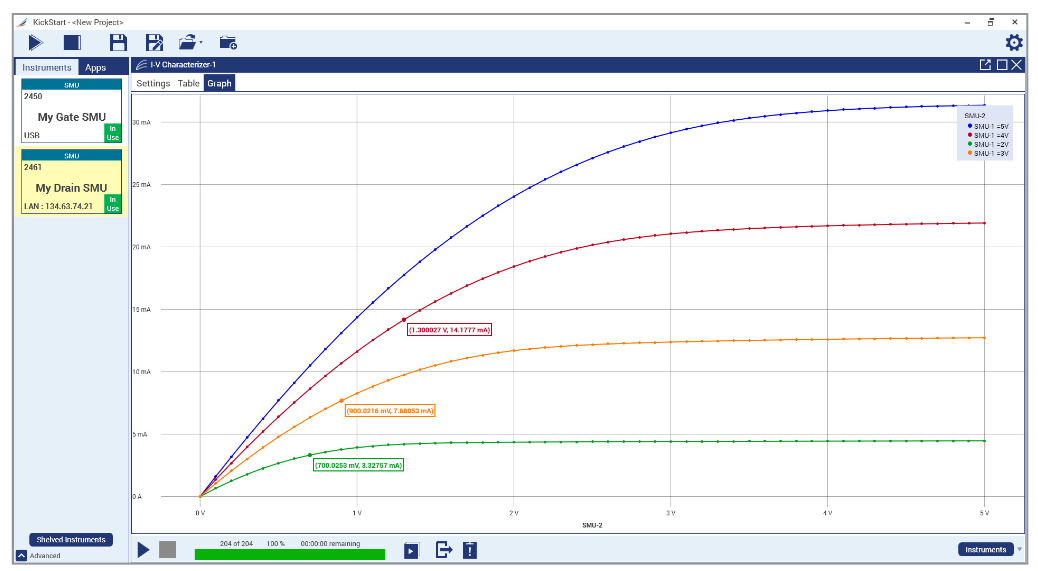

Instrument Control Start-up Software

KickStart instrument control/start-up software enables users to start making measurements in minutes without programming. In most cases, users merely need to make some quick measurements, graph the data, and store the data to disk for later analysis in software environments such as Excel. KickStart offers:

- Configure and control up to four SMU instruments for DC or Pulsed I-V test in either the same app, same project, or a combination of the two.

- Create tests by mixing any of these SMU instruments: 2400 Graphical Series, 2400 Standard Series (DC only), 2600B Series, 2651A, 2657A, and 6430 SourceMeter® SMU (DC only) instruments.

- Differentiate SMU instrument channels and their measurement data using labels that are relevant to your device or module.

- Native X-Y graphing, panning, and zooming; screenshot capturing of graphs.

- Spreadsheet/tabular viewing of data; export data for further analysis.

- Annotating of tests; save test setups.

- GPIB, USB 2.0, Ethernet compliance.

Optional Apps Tailored for your Characterization Needs

The 2450 is an excellent tool to define nearly any DC test you choose for characterizing materials, electronic devices and modules. For more specific needs, Keithley offers oninstrument software apps that alter the 2450's behavior, fitting your instrument to your needs. These apps can be installed directly to your 2450 by connecting to Keithley's KickStart instrument control software and opening the relevant app in KickStart.

I-V Tracer App

Curve tracing analysis is a critical task for many users in the semiconductor development supply chain. Engineers and technicians both hold the traditional curve tracer as the simplest, fastest method for generating characteristic I-V curves on a device. They are heavily used by engineers in failure analysis and incoming inspection to qualify parts, identify counterfeit devices, and to quickly identify the location of a failure on damaged devices. SMUs have typically been limited to predefined sweeps with longer set up times than curve tracers — until I-V Tracer.

Keithley's I-V Tracer app leverages the touchscreen and front-panel knob of the 2450 to allow precise, live control over the SMU output while viewing I-V results of 2 terminal devices. At each individual output level current and voltage are measured and plotted. The small footprint of the SMU enables portable bench top use, reserving high power (kW) traditional curve tracers for special cases. The power envelope of the 2450 allows it to comfortably operate in the low power range of traditional curve tracers like the Tektronix 576 and Tektronix 370A, while offering enhanced low current measurements.

Once installed, I-V Tracer exists on the SMU itself, meaning I-V tracer can be used wherever your SMU can go, without a continuous remote connection. It can also integrate with KickStart to enable simple data collection and comparison on the PC, simplifying the preparation of reports used in failure analysis or teaching labs at colleges and universities.

I-V Tracer capabilities with the 2450:

- Use the full power envelope of the 2450 (max 200 V or 1 A)

- Trace by sourcing voltage or current, positive or negative

- 2 or 4-wire sense

- Compare mode for verifying against a reference device

- Reading table view to see exact measurements

- Easily copy curves and settings to your PC with KickStart

Simplified Programming with Ready-to-Use Instrument Drivers

For users who want to create their own customized application software, native National Instruments LabVIEW® drivers, IVI-C, and IVI-COM drivers are available at www.keithley.com.

Voltage Specifications 1, 2

| Source | Measure3 | |||||

| Range | Resolution | Accuracy (23° ± 5°C) 1 Year ±(% setting + volts) |

Noise (RMS) (<10 Hz)6 | Resolution | Input Resistance | Accuracy (23° ± 5°C) 1 Year ±(% rdg. + volts) |

| 20.00000 mV | 500 nV | 0.100% + 200 μV | 1 μV | 10 nV | >10 GΩ | 0.100% + 150 μV |

| 200.0000 mV | 5 μV | 0.015% + 200 μV | 1 μV | 100 nV | >10 GΩ | 0.012% + 200 μV |

| 2.000000 V | 50 μV | 0.020% + 300 μV | 10 μV | 1 μV | >10 GΩ | 0.012% + 300 μV |

| 20.00000 V | 500 μV | 0.015% + 2.4 mV | 100 μV | 10 μV | >10 GΩ | 0.015% + 1 mV |

| 200.0000 V | 5 mV | 0.015% + 24 mV | 1 mV | 100 μV | >10 GΩ | 0.015% + 10 mV |

Current Specifications1, 2

| Source | Measure3 | |||||

| Range | Resolution | Accuracy (23° ±5°C)4 1 Year ±(% setting + amps) |

Noise (RMS) (<10 Hz)6 | Resolution | Voltage Burden | Accuracy (23° ±5°C) 1 Year ±(% rdg. + amps) |

| 10.00000 nA5 | 500 fA | 0.100% + 100 pA | 500 fA | 10 fA | <100 μV | 0.100% + 50 pA |

| 100.0000 nA5 | 5 pA | 0.060% + 150 pA | 500 fA | 100 fA | <100 μV | 0.060% + 100 pA |

| 1.000000 μA | 50 pA | 0.025% + 400 pA | 5 pA | 1 pA | <100 μV | 0.025% + 300 pA |

| 10.00000 μA | 500 pA | 0.025% + 1.5 nA | 40 pA | 10 pA | <100 μV | 0.025% + 700 pA |

| 100.0000 μA | 5 nA | 0.020% + 15 nA | 400 pA | 100 pA | <100 μV | 0.020% + 6 nA |

| 1.000000 mA | 50 nA | 0.020% + 150 nA | 5 nA | 1 nA | <100 μV | 0.020% + 60 nA |

| 10.00000 mA | 500 nA | 0.020% + 1.5 μA | 40 nA | 10 nA | <100 μV | 0.020% + 600 nA |

| 100.0000 mA | 5 μA | 0.025% + 15 μA | 100 nA | 100 nA | <100 μV | 0.025% + 6 μA |

| 1.000000 A | 50 μA | 0.067% + 900 μA | 3 μA | 1 μA | <100 μV | 0.030% + 500 μA |

Temperature Coefficient (0°–18°C and 28°–50°C) ±(0.15 × accuracy specification)/°C.

Notes

- Speed = 1 PLC.

- All specifications are guaranteed with output ON.

- Accuracies apply to 2- and 4-wire mode when properly zeroed.

- For sink mode, 1 μA to 100 mA range accuracy is ±(0.15% + offset × 4). For 1A range, accuracy is ±(1.5% + offset × 8).

- Rear panel triax connections only.

- Typical noise (RMS) <10 Hz

Resistance Measurement Accuracy (Local or Remote Sense)1, 2

| Source | Measure3 | |||||

| Range | Default Resolution3 | Default Test Current | Normal Accuracy (23°C ±5°C) 1 Year, ±(% rdg. + ohms) |

Enhanced Accuracy4(23°C ±5°C) 1 Year, ±(% rdg. + ohms) |

||

| <2.000000 Ω5 | 1 μΩ | User defined | Source.IACC + Meas.VACC | Meas.IACC + Meas.VACC | ||

| 20.00000 Ω | 10 μΩ | 100 mA | 0.098% + 0.003 Ω | 0.073% + 0.001 Ω | ||

| 200.0000 Ω | 100 μΩ | 10 mA | 0.077% + 0.03 Ω | 0.053% + 0.01 Ω | ||

| 2.000000 kΩ | 1 mΩ | 1 mA | 0.066% + 0.3 Ω | 0.045% + 0.1 Ω | ||

| 20.00000 kΩ | 10 mΩ | 100 μA | 0.063% + 3 Ω | 0.043% + 1 Ω | ||

| 200.0000 kΩ | 100 mΩ | 10 μA | 0.065% + 30 Ω | 0.046% + 10 Ω | ||

| 2.000000 MΩ | 1 Ω | 1 μA | 0.110% + 300 Ω | 0.049% + 100 Ω | ||

| 20.00000 MΩ | 10 Ω | 1 μA | 0.110% + 1 kΩ | 0.052% + 500 Ω | ||

| 200.0000 MΩ | 100 Ω | 100 nA | 0.655% + 10 kΩ | 0.349% + 5k Ω | ||

| >200.000000 Ω5 | - | User defined | Source.IACC + Meas.VACC | Meas.IACC + Meas.VACC | ||

| Temperature Coefficient (0°–18°C and 28°–50°C) | ±(0.15 × accuracy specification)/°C. |

| Source Current, Measure Resistance Mode | Total uncertainty = Isource accuracy + Vmeasure accuracy (4-wire remote sense). |

| Source Voltage, Measure Resistance Mode | Total uncertainty = Vsource accuracy + Imeasure accuracy (4-wire remote sense). |

| Guard Output Impedance | 0.5 Ω (DC) in ohms mode. |

Notes

- All specifications are guaranteed with output ON.

- Accuracies apply to 2- and 4-wire mode when properly zeroed.

- 6.5 digit measure resolution

- Source readback enabled. Offset compensation ON.

- Source Current, Measure Resistance or Source Voltage, Measure Resistance only. For best measurements, use rear panel triax connectors.

Operating Characteristics

| Max. Output Power | 20 W, four-quadrant source or sink operation. | ||||||||||||

| Source Limits | Vsource: ±21 V (≤ 1 A range), ±210 V (≤ 100 mA range). Isource: ±1.05 A (≤ 20 V range), ±105 mA (≤ 200 V range). |

||||||||||||

| Overrange | 105% of range, source and measure. | ||||||||||||

| Regulation | Voltage: Line: 0.01% of range. Load: 0.01% of range + 100 µV. Current: Line: 0.01% of range. Load: 0.01% of range + 100 pA. |

||||||||||||

| Source Limits | Voltage Source Current Limit: Bipolar current limit set with single value. Min. 10% of range. Current Source Voltage Limit: Bipolar voltage limit set with single value. Min. 10% of range. |

||||||||||||

| V-Limit / I-Limit Accuracy | Add 0.3% of setting and ±0.02% of reading to base specification. | ||||||||||||

| Overshoot | Voltage Source: <0.1% typical (full scale step, resistive load, 20 V range, 10 mA I-Limit. Current Source: <0.1% typical (1 mA step, RLoad = 10 kΩ, 20 V range). |

||||||||||||

| Range Change Overshoot | Overshoot into a fully resistive 100 kΩ load, 10 Hz to 20 MHz BW, adjacent ranges: 250 mV typical. | ||||||||||||

| Output Settling Time | Time required to reach 0.1% of final value after command is processed and output slew, 20 V range, 100 mA I-Limit: <200 µs typical. | ||||||||||||

| Maximum Slew Rate | 0.2 V/μs, 200 V range, 100 mA limit into a 2 kΩ load (typical). | ||||||||||||

| Over Voltage Protection | User selectable values, 5% tolerance. Factory default = none. | ||||||||||||

| Voltage Source Noise | Typical 10 Hz–1 MHz (RMS): 2 mV typical into a resistive load. | ||||||||||||

| Common Mode Voltage | 250 V DC. | ||||||||||||

| Common Mode Isolation | >1 GΩ, <1000 pF. | ||||||||||||

| Noise Rejection (typical) |

* Except lowest two current ranges ~90dB. |

||||||||||||

| Load Impedance | 20 nF typical (standard). Stable into 50 μF typical (High-C mode). High-C mode valid for ≥100 µA range s, ≥200 mV ranges. |

||||||||||||

| Max. Voltage Drop Between Force and Sense Terminals | 5 V. | ||||||||||||

| Max. Sense Lead Resistance | 1 MΩ for rated accuracy | ||||||||||||

| Sense Input Impedance | >10 GΩ. | ||||||||||||

| Guard Offset Voltage | <300 µV, typical |

System Measurement Speeds1

Reading Rates (readings/second) typical for 60 Hz (50 Hz):

Script (TSP) Programmed

| Measure | Source-Measure Sweep | |||||||

| NPLC/Trigger Origin | To Mem. | To GPIB | To USB | To LAN | To Mem | To GPIB | To USB | To LAN |

| 0.01 / Internal | 3130 (2800) | 2830 (2570) | 2825 (2600) | 2790 (2530) | 1710 (1620) | 1620 (1540) | 1630 (1540) | 1620 (1540) |

| 0.01 / External | 2170 (2050) | 2150 (2030) | 2170 (2040) | 2160 (1990) | 1670 (1590) | 1580 (1500) | 1590 (1510) | 1580 (1510) |

| 0.1 / Internal | 540 (460) | 530 (450) | 530 (450) | 530 (450) | 470 (410) | 460 (400) | 470 (400) | 470 (400) |

| 0.1 / External | 500 (430) | 490 (420) | 500 (430) | 500 (420) | 470 (400) | 460 (390) | 460 (400) | 460 (400) |

| 1.00 / Internal | 59 (49) | 58 (49) | 59 (49) | 59 (49) | 58 (48) | 58 (48) | 58 (48) | 58 (48) |

| 1.00 / External | 58 (48) | 57 (48) | 58 (48) | 58 (48) | 57 (48) | 57 (47) | 57 (48) | 57 (48) |

SCPI Programmed2

| Measure | Source-Measure Sweep | |||||||

| NPLC/Trigger Origin | To Mem. | To GPIB | To USB | To LAN | To Mem | To GPIB | To USB | To LAN |

| 0.01 / Internal | 3130 (2800) | 3060 (2760) | 3000 (2790) | 3010 (2710) | 1710 (1630) | 1610 (1600) | 1440 (1380) | 1690 (1590) |

| 0.01 / External | 2350 (2200) | 2320 (2170) | 2340 (2190) | 2320 (2130) | 1680 (1590) | 1560 (1570) | 1410 (1360) | 1660 (1560) |

| 0.1 / Internal | 540 (460) | 540 (450) | 540 (460) | 540 (450) | 470 (410) | 470 (410) | 450 (390) | 470 (410) |

| 0.1 / External | 510 (440) | 510 (430) | 510 (440) | 510 (430) | 470 (400) | 470 (400) | 450 (390) | 470 (400) |

| 1.00 / Internal | 59 (49) | 59 (49) | 59 (49) | 59 (49) | 58 (48) | 58 (48) | 57 (48) | 58 (48) |

| 1.00 / External | 58 (49) | 58 (49) | 58 (49) | 58 (49) | 58 (48) | 58 (48) | 57 (47) | 58 (48) |

General Characteristics (default mode unless specified)

| Factory Default Standard Power-Up | SCPI Mode | ||||||||||||||

| Source Output Modes | Fixed DC Level, Memory/Configuration List (mixed function), Stair (linear and log). | ||||||||||||||

| Source Memory List | 100 points max. (SCPI 2400 Mode only). | ||||||||||||||

| Memory Buffer | >250,000 readings. Includes selected measured value(s) and time stamp. | ||||||||||||||

| Real-Time Clock | Lithium battery backup (3 yr. + battery life). | ||||||||||||||

| Remote Interfaces |

|

||||||||||||||

| Digital I/O Interface: |

|

||||||||||||||

| Programmability | SCPI or TSP command sets. | ||||||||||||||

| TSP Mode | Embedded Test Script Processor (TSP) accessible from any host interface. | ||||||||||||||

| IP Configuration | Static or DHCP. | ||||||||||||||

| Expansion Interface | The TSP-Link expansion interface allows TSP enabled instruments to trigger and communicate with each other. | ||||||||||||||

| LXI Compliance | 1.5 LXI Device Specification 2016. | ||||||||||||||

| Display | 5 inch capacitive touch, color TFT WVGA (800×480) with LED backlight. | ||||||||||||||

| Input Signal Connections | Front: Banana. Rear: Triaxial (3-lug). | ||||||||||||||

| Interlock | Active High Input. | ||||||||||||||

| Cooling | Forced air, variable speed. | ||||||||||||||

| Over Temperature Protection | Internally sensed temperature overload puts unit in standby mode. | ||||||||||||||

| Power Supply | 100 V to 240 V RMS, 50–60 Hz (automatically detected at power up). | ||||||||||||||

| VA Rating | 190 volt-amps max. | ||||||||||||||

| Altitude | Maximum 2000 meters above sea level. | ||||||||||||||

| EMC | Conforms to European Union EMC Directive. | ||||||||||||||

| Safety | NRTL listed to UL61010-1 and UL61010-2-30. Conforms with European Union Low Voltage Directive. | ||||||||||||||

| Vibration | MIL-PRF-28800F Class 3 Random. | ||||||||||||||

| Warm-Up | 1 hour to rated accuracies. | ||||||||||||||

| Dimensions | With bumpers and handle: 106 mm high × 255 mm wide × 425 mm deep (4.18 in × 10.05 in × 16.75 in). Without bumpers and handle: 88 mm high × 213 mm wide × 403 mm deep (3.46 in × 8.39 in × 15.87 in.) |

||||||||||||||

| Weight | With bumpers and handle: 4.04 kg (8.9 lbs.). Without bumpers and handle: 3.58 kg (7.9 lbs.). |

||||||||||||||

| Environment | Operating: 0° to 50 °C, 70% R.H. up to 35 °C. Derate 3% R.H./°C, 35° to 50 °C. Storage: –25 °C to 65 °C. |

||||||||||||||

| Accessories Supplied | Test Leads, USB Cable, Ethernet/TSP Cable, Interlock Adapter, Power Cord, Quick Start Guide. |

Ordering Information

| 2450 | 200 V, 1 A, 20 W SourceMeter Instrument |

Supplied Accessories

| 8608 | High Performance Test Leads |

| USB-B-1 | USB Cable, Type A to Type B, 1 m (3.3 ft) |

| CS-1616-3 | Safety Interlock Mating Connector |

| 17469460X | TSP-Link/Ethernet Cable |

| Documentation available at www.tek.com/keithley | |

| 2450 QuickStart Guide | |

| TSP Toolkit Software (available at www.tek.com) | |

| KickStart Startup Software (available at www.tek.com/keithley) | |

| LabVIEW and IVI Drivers (available at www.tek.com/keithley) |

Available Accessories

| Test Leads and Probes | |

| 5804 | Kelvin (4-Wire) Universal 10-Piece Test Lead Kit |

| 5805 | Kelvin (4-Wire) Spring-Loaded Probes |

| 5806 | Kelvin Clip Lead Set |

| 5808 | Low Cost Single-pin Kelvin Probe Set |

| 8606 | High Performance Modular Probe Kit |

| Cables, Connectors, Adapters | |

| 237-ALG-2 | 3-slot Male Triax Connector to 3 Alligator Clips |

| 2450-TRX-BAN | Triax to Banana Adapter. Converts the 4 Triax adapters on the rear panel to 5 banana jacks |

| 7078-TRX-* | 3-slot, Low Noise Triax Cable |

| 7078-TRX-GND | 3-slot Male Triax To BNC Adapter (guard removed) |

| CA-18-1 | Shielded Dual Banana Cable, 1.2 m (4 ft) |

| CAP-31 | Protective Shield/Cap for 3-lug Triax Connectors |

| CS-1546 | Triax 3-lug Special Shorting Plug. Shorts center pin to outer shield |

| CS-1616-3 | Safety Interlock Mating Connector |

| Communication Interfaces and Cables | |

| 7007-1 | Shielded GPIB Cable, 1 m (3.3 ft) |

| KPCI-488LPA | IEEE-488 Interface for PCI Bus |

| KUSB-488B | IEEE-488 USB-to-GPIB Interface Adapter |

| Rack Mount Kits | |

| 4299-8 | Single Fixed Rack Mount Kit |

| 4299-9 | Dual Fixed Rack Mount Kit |

| Test Fixtures | |

| 8101-PIV | DC Test Fixture |

| Software Options | |

| I-V Tracer | Graphical SMU Curve Tracer Software |

| Kickstart | Instrument Control Software |

| ACS Basic Edition | Semiconductor Parametric Test Software for Component and Discrete Devices |

Available Services

| 2450-3Y-EW | 1 Year Factory Warranty extended to 3 years from date of shipment |

| 2450-5Y-EW | 1 Year Factory Warranty extended to 5 years from date of shipment |

| C/2450-3Y-17025 | KeithleyCare® 3 Year ISO 17025 Calibration Plan |

| C/2450-3Y-DATA | KeithleyCare 3 Year Calibration w/Data Plan |

| C/2450-3Y-STD | KeithleyCare 3 Year Std. Calibration Plan |

| C/2450-5Y-17025 | KeithleyCare 5 Year ISO 17025 Calibration Plan |

| C/2450-5Y-DATA | KeithleyCare 5 Year Calibration w/Data Plan |

| C/2450-5Y-STD | KeithleyCare 5 Year Std. Calibration Plan |

Warranty Information

| Warranty Summary | This section summarizes the warranties of the 2450. For complete warranty information, refer to the Tektronix warranty page at www.tek.com/service/warranties/warranty-2. Any portion of the product that is not manufactured by Keithley is not covered by this warranty and Keithley will have no duty to enforce any other manufacturer's warranties. |

| Hardware Warranty | Keithley Instruments, Inc. warrants the Keithley manufactured portion of the hardware for a period of one year from defects in materials or workmanship; provided that such defect has not been caused by use of the Keithley hardware which is not in accordance with the hardware instructions. The warranty does not apply upon any modification of Keithley hardware made by the customer or operation of the hardware outside the environmental specifications. |

| Software Warranty | Keithley warrants for the Keithley produced portion of the software or firmware will conform in all material respects with the published specifications for a period of ninety (90) days; provided the software is used on the product for which it is intended in accordance with the software instructions. Keithley does not warrant that operation of the software will be uninterrupted or error-free, or that the software will be adequate for the customer's intended application. The warranty does not apply upon any modification of the software made by the customer. |