Contact us

Request Services Quote

Parts Ordering

Request Sales Contact

Request Technical Support

Need help on product selection? Chat with Sales

Available 6:00 AM – 5:00 PM PST

Call us at

Available 6:00 AM – 5:00 PM (PST) Business Days

Download

Download Manuals, Datasheets, Software and more:

Feedback

Have feedback? We'd love to hear your thoughts.

Whether positive or negative, your feedback helps us continually improve the Tek.com experience. Let us know if you're having trouble or if we're doing an outstanding job.

- Tektronix

- Semiconductor Testing Systems by Keithley

- ACS Automated Characterization Suite Software

ACS Standard Edition Automated Characterization Suite Software Datasheet

More Information

- Keithley Automated Characterization Suite (ACS) Software

- Product Support

- Explore more Software models

One Powerful Software Solution A Wide Range of Hardware Configurations

Keithley’s Automated Characterization Suite (ACS) is a flexible, interactive software test environment designed for device characterization, parametric test, reliability test, and even simple functional tests. ACS supports a wide array of Keithley instrumentation and systems, hardware configurations, and test settings, from a few benchtop instruments for use in a QA lab to fully integrated and automated rack-based parametric testers.

ACS offers exceptional testing and analysis flexibility, plus its intuitive GUI helps novice users be productive almost immediately, regardless of their level of programming experience. The GUI simplifies configuring test instrumentation, making I-V measurements, getting results, and analyzing them quickly because no coding is required. Even if you’re an infrequent user, you can go from creating a new test setup to characterizing new devices in a fraction of the time required by older test development approaches. Just as important, ACS provides all the tools you need to set up tests, analyze data, and export your results without ever leaving the ACS environment.

Key Features

- Supports the following test modules: GUI, Lua Script, Python and C

- Supports a wide array of instruments and probers to accommodate a broad range of applications

- Intuitive GUI simplifies I-V tests, analysis, and results from benchtop to fully automated parametric testers to enhance user experience

- Develop and execute tests at the device, sub-site, site, wafer, and cassette level for increased test capability

- Intuitive GUI for test plan development and interactive operation

- Interactive and real-time data plotting accelerates review of test results

- Highly portable test projects with minimal or no modifications

- Supports multiple groups of TSP® instruments for parallel testing to increase productivity

- Flexible, modular software accommodates evolving and mature test requirements

- Customizable for parameters extraction by special algorithms for added flexibility

- Customized data reporting and uploading (FTP, DB, etc.)

- Simplified instrument configuration using the automated hardware management tool

- Windows 11 and 10 compatible

Broad Range of Applications

ACS-based Integrated Test Systems are complete solutions for applications such as device characterization, parametric die sort, high power semiconductor component characterization, parametric test, and wafer level reliability testing. When paired with appropriate semi-automatic and fully-automatic probe stations, their hardware configurations and test project development can be easily optimized for specific tasks. ACS leverages the on-board test script processors in Series 2400 and 2600 System SourceMeter SMU instruments into a multi-processor environment that’s ideal for true parallel test in both single- and multi-site configurations. This multi-processor environment provides high parallel throughput while speeding and simplifying test project development. Multi-site testing capabilities are embedded throughout ACS from the wafer description utility to the test results output file or binning file, for example:

- Multi-site parallel testing brings the highest possible throughput for both parametric die sort and WLR applications

- Configurable for special applications like MEMS testing

- Easily customize test flows with user access points (UAPs) that execute scripts or call custom utilities

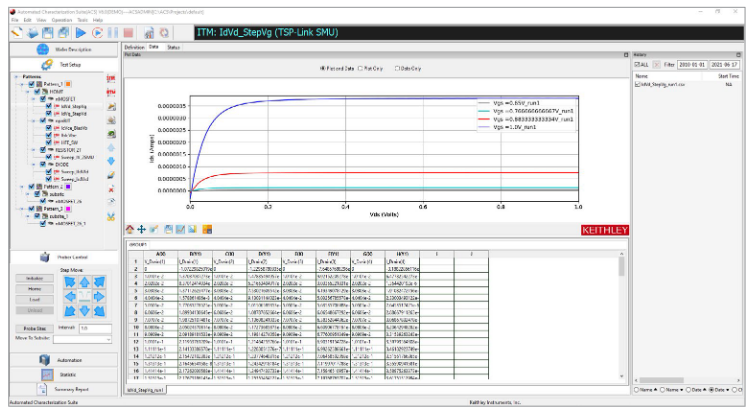

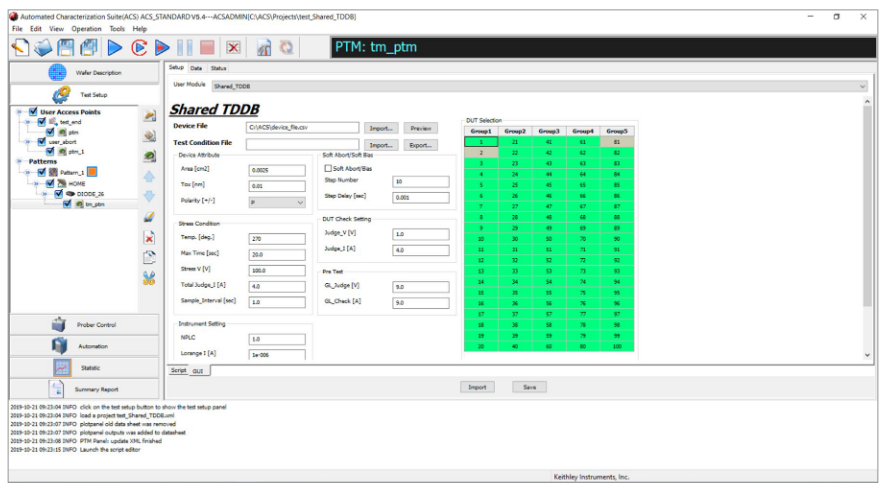

The intuitive GUI simplifies I-V tests, analysis, and results from benchtop to fully-automated parametric testers.

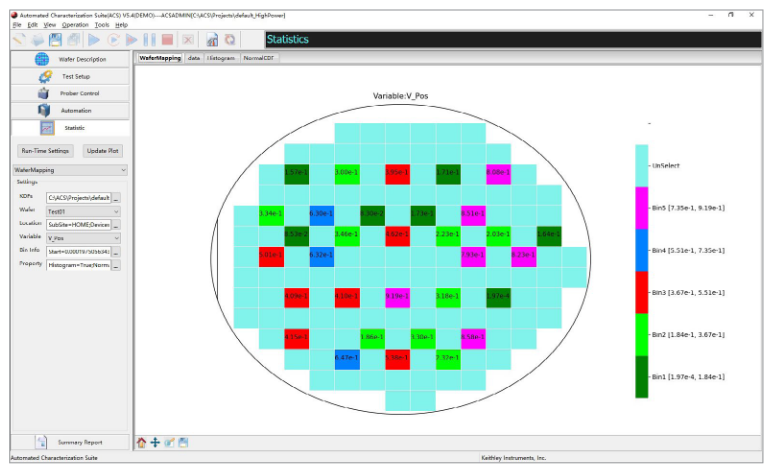

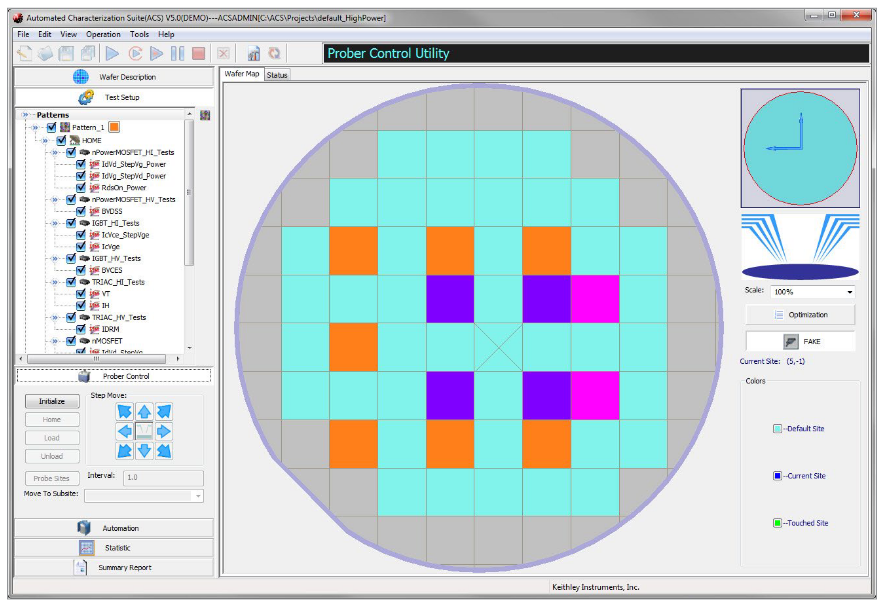

Wafer and binning map tools allow you to browse through the test results on either a wafer-by-wafer or site-by-site basis. You can also overlay traces from multiple sites to make quick comparisons. Flexibility with Programming Preferences for Characterization Applications

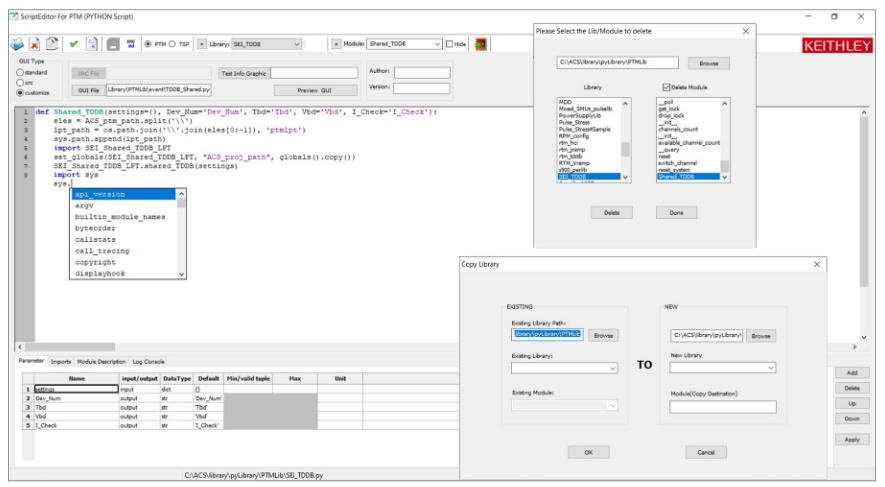

Script Editor is an independent tool with graphical user interface (GUI) that helps to process all the operations needed to prepare an ACS user library. A user library is a collection of user modules written using Python or Test Script Processor (TSP®) script to perform instrumentation control, data analysis and system automation test tasks. Script Editor provides intuitive ways to create and develop GUI design and management for libraries and modules.

With the Script Editor tool, user-friendly graphical interfaces process different operations related to user libraries and modules management. It starts from creating a library and module from scratch or copying one from an existing user library or module as a base for the new library and modifying it. Also, it’s easy if a user wants to delete a library or delete some modules from a library. The Script Editor tool provides a comparatively powerful editor to develop Python code and TSP code for the functionality needed by the test, including syntax tips and for checking purposes. There are also features that help to define and automatically assign input/output parameters to the test module.

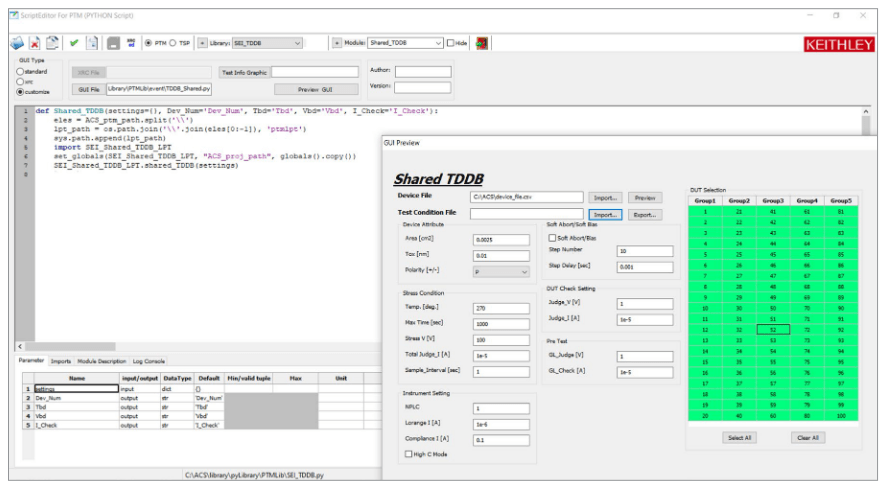

Script Editor provides three ways to design a graphical user interface for the test module: STANDARD GUI is automatically generated with concise layout; XRC or CUSTOMIZABLE GUIs are developed by the SRC editor or Python code for situations that need a more complex GUI layout. Users can choose any type based on their different needs.

Script Editor allows users to choose STANDARD GUI, XRC, or Python code for situations that need a more complex GUI layout. The ACS platform automatically recognizes the user libraries and modules. The user just needs to easily import the user library and module developed by the Script Editor, configure the test settings presented by the friendly GUI, and then run it in the ACS environment.

Interactive probe station control speeds and simplifies test development and debugging by combining interactive testing with manual probe station control. Automate Your Data Gathering Processes

The wafer prober automation option for ACS makes it easy to interface a variety of popular semi or fully automatic wafer probe stations into your test setup to capture large amounts of data quickly. This option includes a wafer description utility (for creating a virtual wafer to use in creating wafer-level sampling plans), real-time wafer maps with binning capabilities (for designating a device’s disposition before it’s packaged, in die sorting, etc.), a cassette sample plan utility (for designating which wafers are to be tested), and a post-test cassette and wafer review utility (for exploring and comparing test results from multiple wafers interactively).

Many of the tools and capabilities built into ACS enhance automated device characterization:

- Wafer and cassette level automation

- Limits file generation tool

- Test results binning, including interactive binning plot

- Test map to map device and tests to sites and subsites

- Interactive probe station control mode

- Real-time plotting

- Single or per-wafer Keithley data file

- SQLite™ database and binning file output options

- Lot summary report generator

- Integrated support for Keithley Series 2600B, Series 2400 Series and 2400 Touchscreen Source Measure Units, and the 2651A and 2657A High Power System SourceMeter® SMU instruments

- Integrated scripting editor and GUI builder

- Integrated support for C (with Series 4200 Parameter Analyzer only), Python, and Lua (for Series 2400 and 2600) programming languages

Share Test Projects and Results

ACS offers a common set of key elements that work across a wide range of hardware configurations, which saves time and increases productivity. Systems perform consistently from one hardware implementation to another, so, for example, it’s easy to transfer your knowledge of an ACS-based system used in single-device component characterization to another designed for wafer level testing.

Similarly, test projects and sequences you create for one Keithley ACS hardware configuration will run on compatible setups in other test settings with little or no modification. This portability across a range of configurations reduces the effort involved in transferring a new device from one lab or department to another and simplifies comparing results obtained in various test settings. This is possible because ACS employs common open-standard file interfaces for projects, wafer maps, output files, etc., as well as common test libraries and instrument drivers, so you can be confident of high results correlation whether your tests are run on a system with a single Series 2400 and 2600 SMU instrument or a fully automated custom die sort tool with dozens of these instruments.

Maximize the Productivity of Your Keithley Hardware

The tools in ACS simplify test development and maximize the speed of each Keithley instrument linked into the system. For example, ACS builds on the throughput advantages inherent in Keithley’s Series 2600B System SourceMeter SMU instruments. These advantages include:

- On-board TSP technology in each instrument allows each 2400 or 2600 to operate independently of the ACS system's controller

- TSP-Link® Technology high speed communications bus networks multiple Series 2400 and 2600 SMU instruments together

- True parallel test execution

- Precision timing

Together, ACS and Keithley TSP-based hardware offer the highest throughput in the industry to lower the cost of test without requiring you to spend time learning new programming concepts or languages before getting the data needed to accomplish your goals.

Add More Hardware to Adapt to Changing Needs

High scalability and a flexible architecture simplify configuring an ACS system to match your specific testing requirements or to upgrade an existing system to handle new test needs as they evolve. Our wide range of source-measure and switching capabilities provides a solid foundation for configuring customized applications, because ACS software with PyVisa can control virtually any instrument or peripheral with a standard hardware interface. For example, Tektronix oscilloscopes and thirdparty LCR meters can be easily integrated into any ACS system and drivers are available for popular instruments. Also, ACS’s integrated scripting environment can control any GPIB instrument the application may require, such as a hot chuck controller.

Many ACS systems are configured using one or more Series 2400 and 2600 SMU instruments, which are optimized for precision sourcing and measurement synchronization to capture high speed events. These systems offer unmatched testing speed and accuracy because they provide a SMU-per-pin architecture. ACS system configurations can support any number from 2 to more than 40 SMU instruments in a single rack for true parallel characterization applications.

ACS also makes it easy to integrate other instruments into your system to meet specialized test requirements, such as:

- Simplified instrument configuration using the automated hardware scan tool

- High channel count switching Keithley 707B Six-slot Switch Mainframe

- Combination of switching and measurement Keithley Series 3700A Switch/Multimeters

- Higher resolution, lower current, or other capabilities such as C-V or pulse testing Keithley 4200A Parameter Analyzer

- 40 V/50 A range (80 V/100 A when connecting two units) of Keithley 2651A or 3 kV/120 mA range of 2657A High Power System SourceMeter SMU instruments

ACS Pre-installation Software Requirements

Minimum Configuration for a Computer

Operating System Windows 7 × 86 (32-bit), or Windows 7 × 64 (64-bit), Windows 10 × 86 (32-bit), or Windows 10 × 64 (64-bit), or Windows 11 × 64 (64-bit) CPU 2 cores or higher, 1 gigahertz (GHz) or faster processor or System on a Chip (SoC) System Memory (RAM) 8 GB for 32-bit or 16 GB for 64-bit Hard Disk 16 GB for 32-bit OS 32 GB for 64-bit OS Graphics Card DirectX 9 or later with WDDM 1.0 driver Screen Display 1024 × 768, 32-bit True Color

Recommended Configuration for a Computer

Operating System Windows 10 × 86 (32-bit) or Windows 10 × 64 (64-bit) CPU 4 cores or higher, at least 2 gigahertz (GHz) or faster processor System Memory (RAM) 8 GB for 32-bit or 16 GB for 64-bit Hard Disk 32 GB for 32-bit OS 64 GB for 64-bit Graphics Card DirectX 9 or later with WDDM 1.0 driver Screen Display 1280 × 1024, 32-bit True Color Ordering Information

ACS Basic Edition

ACS-BASICFL ACS Basic Edition Instrument Control Software; Perpetual Floating License* ACS-BASICFL-UP Annual Maintenance License for extending support of Perpetual Floating License * Perpetual Licenses: The software can be used indefinitely; license does not expire but updates/support only available for the first 12 months. Support can be extended by purchasing a maintenance license. If a perpetual license goes out of support, all features will be frozen to the last released version before the support expired. The software will continue to work, but you cannot get any updates newer than the support expiration date.

• Maintenance Licenses - Apply to perpetual licenses only. Maintenance license is an extension license that extends the period of support of an original perpetual license for 12 months.