Contact us

Call

Call us at

Available 6:00 AM – 5:00 PM (PST) Business Days

Download

Download Manuals, Datasheets, Software and more:

Feedback

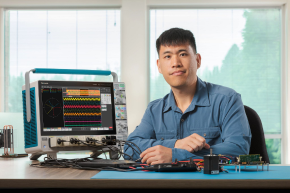

Solutions to the Challenges of EV Traction Inverter Testing

Multichannel Tektronix Oscilloscopes and EA Elektro-Automatik Bidirectional Power Supplies

Enhancement of EV traction Inverter design contributes to improved vehicle range and performance. In-depth test and analysis of current and next-generation 3-phase inverters requires:

Reliable Hardware

Seamless Compatibility

In-Depth Analysis

Intuitive Operation

Precision Measurements

Your sales representative can provide assistance in designing a custom solution to address your requirements. A typical solution includes:

- Bidirectional Power Supply (EA 10000 Series)

- 5 Series B MSO oscilloscope with 1GHz bandwidth (MSO58B (1) (5-BW-1000) 8-channel )

- Automotive Analysis Software Bundle for IMDA, DQ0 Analysis and serial bus decoding (5-PRO-AUTOMOTIVE-3Y)

- High voltage differential probe (THDP0200 (3) 200 MHz +/-750 V)

- 120 MHz, 30 Arms, spilt-core AC/DC current probe (TCP0030A (3))

- 8-channel logic probe (TLP058 (1))

- TekScope PC Software for off-line analysis (TEKSCOPE-ULTIMATE)

- TekDrive Data Storage Subscription (TEKDRIVE-STARTER)

Complete the form to request contact from sales and we will quickly route your request to a sales representative or to one of our distribution partners.

Solution Benefits and Capabilities

Oscilloscopes :

- Motor drive analysis filters for stable triggering on PWM signals

- Display of phase magnitude, angle, and balance information for 3-phase signals

- High-speed data acquisition for identifying problems during dynamic load changes

- Support for common angle, speed and torque sensors

- DQ0 analysis for evaluating controller performance

- Decoding capability for automotive control buses

- A wide range of available current and voltage probes

Power Supplies:

- High voltage, more than 800 V, and high current power sourcing to meet the traction inverter and motor power demands

- High current sinking for testing regenerative braking performance

- Ability to return braking energy to the facility for reuse

- Robust power source thermal management to maintain a safe operating temperature under all load conditions