Measuring Current using Shunt Resistors

There are different techniques for measuring the current flowing in a circuit. Employing Ohm’s law by inserting a shunt resistor of a precisely known value in the circuit is a common and straightforward way of measuring the current in the circuit. This post:

- Defines and describes shunt resistors and their applications

- Discusses key characteristics of shunt resistors

- Gives an overview of DMMs and oscilloscopes and how they are used with shunt resistors

- Lists advantages and disadvantages of measuring with shunt resistors

- Introduces the concept of isolated current shunt probes for oscilloscopes

What is a shunt resistor?

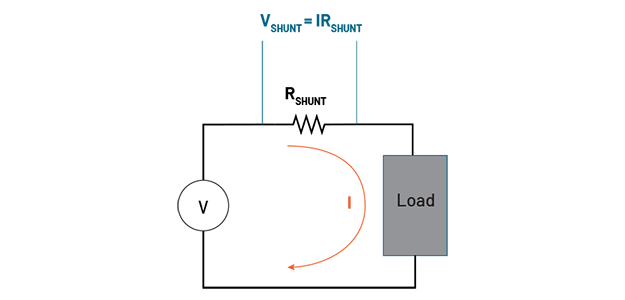

A shunt resistor is a precision component inserted within a circuit to measure current. In ammeters designed to measure current using a sensitive meter movement, the shunt resistor was wired in parallel with the meter movement, thus “shunting” current away from the movement. Today this terminology is commonly applied to resistors which are inserted into a circuit to cause a small voltage drop proportional to the current flowing in the circuit. This drop can then be measured with a voltmeter or oscilloscope and used to calculate the current flowing through the circuit using Ohm’s law by simply dividing the measured voltage by the resistance value.

Figure 1. A shunt resistor of known resistance may be inserted in series with a load to measure current in the load. By measuring the voltage drop across the known resistor the current can be calculated as I = V/R.

Types of Shunt Resistors

Shunt resistors, current sense resistors and current viewing resistors operate identically, but may differ in performance and intended use. A CVR, or current viewing resistor, is another term for a shunt resistor. It usually refers to a low value shunt resistor that has been designed with a controlled frequency response and very accurate resistance for use in precision dynamic measurement applications. Although these can be incorporated into a product design, it is more common to use them in prototyping or to provide temporary test points. CVRs are often provided with software models that include parasitic elements to facilitate accurate simulation.

As noted above current sense resistors also serve as shunt resistors, but this term is commonly applied to resistors that are an integral part of a product design. They are paired with an amplifier to measure the voltage drop across the resistor. This can range from a standalone current sense amplifier to a fully integrated power monitoring IC that handles signal conditioning, isolation and analog-to-digital conversion.

Shunt Resistor Characteristics

Shunt resistors are typically designed with low resistance to minimize voltage drop and I2R power loss dissipated through heat as the Joule effect. They must have adequate power ratings to carry the current in the circuit under test. Like any other component, they are not “ideal”, so the series inductance is also an important concern since inductance will impede current changes.

Shunt resistors designed for use in AC measurements are often physically flat and wide. Due to the skin-effect, alternating current tends to flow on the outside of conductors. Thus, designers often choose a flat, wide conductor to optimize surface area and keep AC impedance low.

Since the resistances of shunts can be very small, even the lead and contact resistance can become comparable as order of magnitude to the shunt resistance value itself. For this reason, some shunt resistors have four terminals to enable Kelvin connections. This provides a physical separation between the current and voltage electrodes to null their effect on the measurement. In fact, two terminals are used to carry the current and two are used to connect to a voltmeter. Since voltmeters have a high input impedance, this effectively eliminates current flow through the voltage measurement terminals and minimizes the effect of any resistance in the voltage connections.

Choosing the appropriate shunt resistor for a PCB design is a critical task for design engineers. The result is usually a tradeoff between electrical ratings, package form factor, power rating and even the unit price, especially when designing for large volume production.

Below are the key considerations to guide you in choosing the ideal shunt resistor.

- Accuracy and Tolerance: Precision required determines specific boundaries for the component selection. For precise measurements, select a resistor with low tolerance (±0.1% or better). Higher tolerance may introduce errors in sensitive applications.

- Parasitic Inductance: In high-frequency or fast-changing current measurements, inductance becomes critical. Low-inductance resistors are ideal for these scenarios, as they minimize the potential for measurement errors and ensure clean, accurate signals.

- Temperature Coefficient: It is essential to ensure the resistor has a low temperature coefficient (TCR), so its accuracy remains stable, even in fluctuating temperature conditions. Temperature coefficient is generally linked to Power Dissipation considerations.

- Current Range/ Power Rating: The current range and power rating must be considered together. The maximum value of the current range and the resistor value will determine the maximum power dissipation. However, one must also consider the minimum current difference to be measured and ensure that the shunt resistor is large enough to produce measurable voltage drop. Power rating usually determines the size and the form factor.

- Physical Size and Form Factor: Choose a resistor from among those satisfying the above conditions that fits within the space available in your system, whether you need a surface-mount or through-hole design.

Applications of Shunt Resistors

Shunt resistors are used in various applications, thanks to their simplicity, low-cost and performance. They are widely used in applications such as:

- General Test and Measurement: Shunt resistors may be built into ammeters or may be external devices connected in series with a load under test.

- Power supplies and industrial equipment: For current monitoring and fault detection.

- Electric motor drives and control systems: To measure and regulate current for optimized performance.

- EVs: Monitoring charge and discharge currents with high precision.

- Mobile devices: Current sense resistors are often used to monitor current draw in low current devices.

Where to place a shunt resistor in a circuit

In most applications, the shunt resistor is placed with one leg close to ground (usually referred to as “low side current sensing”). This will reduce the common mode voltage applied to the voltmeter used to measure the shunt. Designers must take care that the return path for measurements is not shared with AC signals or coupled with AC signals which would introduce noise in measurements.

In some cases, it may not be practical or desirable to ground a shunt resistor. For example, recently automotive power designers have considered the advantages of connecting the shunts directly to the power source, a configuration that allows then to rapidly detect potential failure on the downstream path hence giving a chance to protect the circuitry. This of course means the shunt must be inserted at an ungrounded node, so special care should be taken to observe the common mode voltage specifications for the measuring system used to measure the voltage drop.

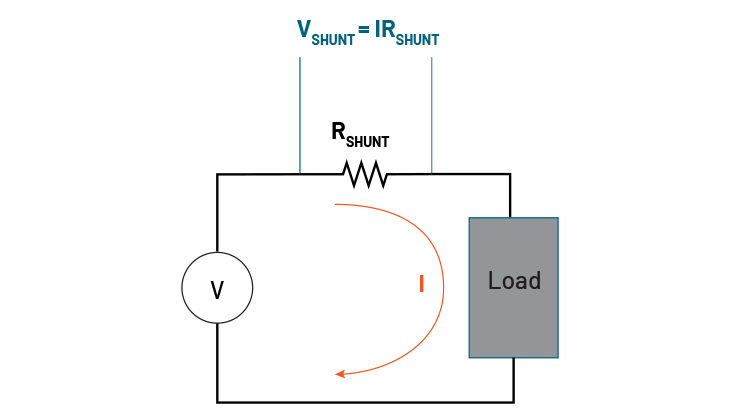

Figure 2. When possible, shunt resistors such as the lower current viewing resistor (CVR) in this circuit, should be grounded. This minimizes common mode voltage and allows the connection of a ground-referenced probe. Measuring the upper CVR requires a differential measurement with high common mode rejection (see Using an Isolated Current Shunt Probe below).

Instruments and Current Measurements with Shunt Resistors

In general shunt resistors enable precise measurement of electrical current by generating a small, measurable voltage drop. To accurately interpret this voltage requires instruments like ammeters, digital multimeters (DMMs) and oscilloscopes.

Measuring Current with Ammeters and Digital Multimeters (DMMs)

Ammeters and DMMs are ideal for measuring direct current or alternating current. They are the tool of choice for making quick, accurate measurements on AC and DC power supplies. For current measurement meters usually incorporate one or more shunt resistors within the instrument. Different resistors can be used to enable multiple current ranges. They can be extremely accurate and precise -- for example, a Keithley DMM7510 precision bench multimeter can measure DC current in pA (1x10-12 A) and AC current in nA (1x10-9 A). Most DMMs can easily make RMS measurements on 50/60 Hz and some can measure up into kHz, but meter leads usually top out below 1 MHz.

Figure 3. DMMs have built-in shunt resistors for precisely measuring current. This Keithley DMM7510 can measure DC current in pA (1x10-12 A). Note the 3 A current input in the lower right, which is connected to one of the internal shunt resistors. A 10 A input is also available on the rear of this DMM.

Historically analog ammeters (galvanometers) sensed current by running it through a coil in a sensitive meter movement. In these instruments shunt resistors were used as current dividers to enable the meter measure higher currents by “shunting” current away from the movement. Even though most modern instruments measure the voltage drop across the shunt resistor, the “shunt” terminology has stuck.

- Digital Multimeters (DMMs) are capable of measuring voltage, resistance, and current. DMMs typically have one or more built-in current shunts for measuring AC or DC current. DMMs may also be used in AC or DC voltage mode to measure the voltage drop across external shunt resistors. When using a DMM with a shunt resistor, the multimeter is connected across the resistor terminals to measure the voltage drop and display the corresponding current value. DMMs are excellent for accurate current readings in both low- and high-current circuits, making them suitable for a wide range of applications.

- Ammeters are designed specifically for current measurement and are ideal for applications requiring continuous monitoring of current in a circuit. Ammeters are often built into power supplies or other equipment for real-time feedback.

Note: A common mistake is for a user to accidentally connect a DMM configured for a current measurement across a high-energy source. This connects the low-resistance shunt across the source, resulting in a short circuit. For this reason, high-current inputs on DMMs use separate jacks and are protected with fuses. After making a current measuring with a DMM, it’s best practice to remove the test lead from the current jack and plug it into the high-impedance voltage input.

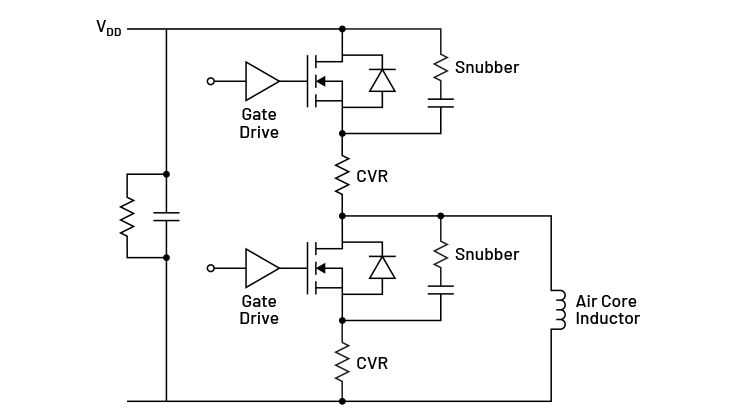

Measuring Current with Oscilloscopes

Oscilloscopes are generally not as accurate as DMMs for DC and low-frequency AC current measurements, but they are invaluable for measuring transient and fast-changing currents with frequencies into the megahertz. Oscilloscopes also allow engineers visualize current relative to other activities and parameters in devices under test, including voltages, switching events, sensor signals and control signals. This is particularly useful in testing systems like high-speed digital systems, traction inverters and power supplies in which current can spike or drop rapidly in response to load changes.

To measure current, oscilloscopes must be equipped with probes capable of transducing current into voltage. The transduction can be either based on magnetic sensors or on shunt resistors. Both methods provide the oscilloscope with a voltage signal that can be digitized and displayed versus time.

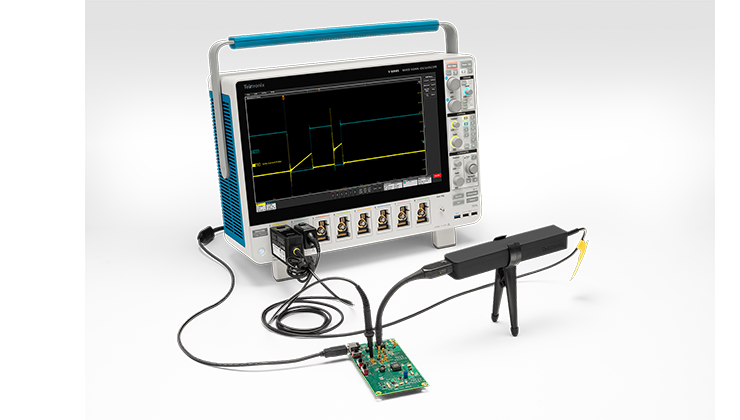

Figure 4. Oscilloscopes can measure current by using clamp-on current probes, or by measuring the drop across a shunt resistor. In this example the resistor is not grounded, so a shunt current probe is being used.

Magnetic Current Probes

Transformer, Rogowski and Hall Effect probes work in tandem with oscilloscopes to measure current without having to break the circuit. Transformers and Rogowski coils can only be used to measure AC. Thus, AC/DC current probes for oscilloscopes combine transformer action with Hall Effect sensors. These probes are convenient and effective when a length of wire or a bus bar can be incorporated in the DUT, either by design or as a temporary test point. However, even an excellent clamp-on current probe such as a TCP0030A is limited to 120 MHz, and can measures down to mA. Even though they do not require “breaking the circuit”, it is important to remember that magnetic probes do present an inductive load to the circuit under test, which can be significant at high frequencies. At 120 MHz, the TCP0030A has an insertion impedance of 0.85 Ω.

Voltage Drop Across a Shunt Resistor

Measuring the voltage drop across a known resistance is a straightforward way to measure current in a circuit. Any known, low-value series resistor within the DUT can serve as a current measuring shunt. Alternatively, a test point may be added by inserting an appropriately rated resistor in series with a load. If the oscilloscope allows for measurement scaling (often found in the probe menus), one can divide voltage readings by a constant resistance value to read out in amperes.

- As noted above, ideally the shunt resistor would have one leg tied to ground. If one leg of the resistor is grounded, then a passive ground-referenced probe may be used. If one terminal cannot be grounded, then a differential voltage probe should be used. Even when using a differential probe, best practice is to place the shunt resistor close to ground to minimize common mode voltages.

- The resistance of the shunt must be much lower than that of the oscilloscope or probe.

- For high-frequency measurements the parasitic capacitance and inductance of the shunt resistor will come into play, and a sense resistor or CVR designed for use in high-frequency applications should be used.

While passive and differential voltage probes may be used to measure voltage waveforms across a shunt resistor, they also have some disadvantages:

- They often attenuate the signal, resulting in lower signal to noise ratios.

- High input impedance and shunt capacitance impacts noise performance.

- For shunts that cannot be grounded

-

- Passive probes cannot be used

- Differential probes may not support adequate common mode voltage

- Common mode rejection is often insufficient to prevent noise

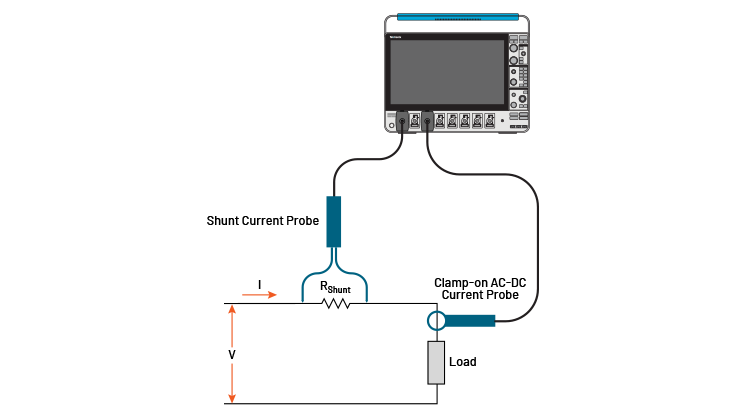

Figure 5. A TICP Series IsoVu Isolated Current Probe is designed for making high-bandwidth, low-noise current measurements on floating shunt resistors. Typical applications include ungrounded current viewing resistor measurements like the one shown on Figure 2.

Using an Isolated Current Shunt Probe

In cases where noise must be strictly controlled, a special current shunt probe may be used. Tektronix TICP Series IsoVu™ Isolated Current Probes are one such series of probes. These probes are especially designed to make low noise, high-bandwidth measurements across shunt resistors. The key characteristics of the new TICP Series isolated current probes are:

- Bandwidths of 250 MHz, 500 MHz or 1 GHz

- Low attenuation and 50 Ω input impedance when used with 1X tips. This helps to maximize signal-to-noise ratio.

- Over 1000 V common mode voltage for use on high-voltage power converters. This is much higher than typical differential voltage probes.

- 90 dB common mode rejection ratio at 1 MHz, which is significantly higher than typical differential probes.

Advantages and Disadvantages of Using Shunt Resistors versus Magnetic or Hall Effect Sensors

Using shunt resistors to measure current has several advantages compared to using magnetic or Hall Effect sensors:

- Accuracy: Shunt resistors provide highly accurate current measurements and can be designed to minimize the impact to the circuit being measured. Since shunt resistors are essentially current-to-voltage converters, measurement accuracy depends on the accuracy of the instrument used to measure the voltage drop across the shunt, as well as the uncertainty in the value of the resistor.

- Cost-Effective: Compared to other current measurement methods, such as magnetic and hall effect sensors, shunt resistors are low-cost and easy to implement.

- Versatile: Suitable for both low and high-current systems, depending on the material and construction.

The main disadvantages of using shunt resistors to measure current are:

- Breaking the circuit: Unlike magnetic or Hall effect sensors, a shunt resistor must be inserted in the circuit being measured. For wired connections this is straightforward – the resistor can be placed in series. For circuit boards, the board must be designed with test points to avoid having to cut traces.

- Voltage drop: Putting a shunt resistor between a source and load reduces the voltage available to the load.

- Power dissipation: A shunt resistor will dissipate power as a function of the square of the current (P = I2R).

In summary, shunt resistors offer a reliable, cost-effective, and precise method for measuring current in various applications. By introducing a small, known resistance into the circuit, they allow for current calculation via the voltage drop across the resistor, leveraging Ohm’s law. Whether used with multimeters, oscilloscopes with passive, differential or isolated current probes, shunt resistors can adapt to a range of current measurement needs, from low-frequency to high-frequency applications and for a wide range of currents. While they have limitations—such as requiring circuit insertion, voltage drops, and power dissipation—these components are indispensable for current measurements.