Industry-Leading Power Supply Performance for Testing Next-Generation Technology

To keep pace with the rapidly advancing technology and innovation in the market, test instrument manufacturers must continuously innovate their platforms to enable thorough testing of new products. EA Elektro-Automatik (EA) DC programmable power supplies and electronic loads are up to the challenge. EA programmable power supplies incorporate industry-leading technology into its power instrumentation to address the testing challenges of evolving technologies such as electric vehicles, renewable energy and aerospace vehicles. The following describes EA’s industry-leading technology, enabling capacity and performance for testing current and future advanced technology products and powering and controlling new manufacturing processes.

Adaptability to the widest range of test requirements – more testing in one piece of equipment

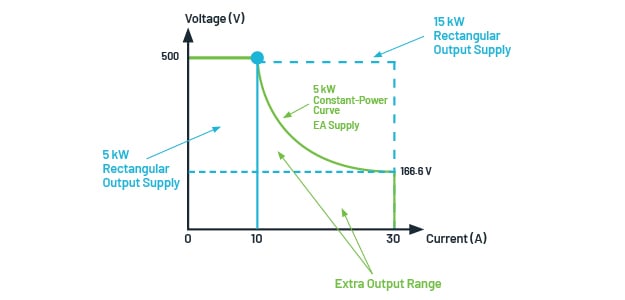

The EA autoranging output (or input characteristic for a load) enables full power delivery (or absorption) over the widest voltage range than any other manufacturer’s power instruments. EA programmable power supplies and electronic loads can operate at full power from the maximum rated voltage all the way down to 1/3 of the maximum rated voltage. For applications such as battery testing, an EA bidirectional power supply with its true autoranging characteristic can simulate continuous battery discharge under maximum load or perform a fast charge on a battery at a high initial current. Figure 1 compares EA’s true autoranging performance with that of a conventional supply, which has a rectangular output characteristic. To provide the same current capacity and full load performance of an EA true autoranging power supply, a conventional rectangular output power supply would have to have three times the capacity. The use of a conventional power supply adds significant cost and space to a test system compared with an EA true autoranging power supply.

Figure 1. Comparison of a 5 kW EA power supply output (red outline) with 5 kW and 15 kW conventional rectangular output power supplies (blue outlines)

Highest power in the most compact programmable power instruments

EA programmable power supplies incorporate SiC high voltage, high power technology to provide power supplies with the greatest power density. The EA-10000 Industrial Series instruments pack 30 kW in a 4U high enclosure and 60 kW in only a 6U high, 19-inch wide, full rack instrument. Five of the 60 kW instruments can reside in a 42U high rack to provide up to 300 kW. All this power consumes only 6.5 sq ft of floor space on a manufacturing floor, saving space for future manufacturing capacity and minimizing manufacturing overhead costs.

In addition, EA instruments have the highest voltage capacity. EA instruments have a 2000 V capacity with 80 A in 60 kW models and 1000 A with as much as 80 V in 30 kW models. The high capacity with a wide current range enables a single instrument to address current and future requirements.

Highest energy efficiency in bidirectional power supplies saves companies money

EA programmable power supplies have included energy reduction and sustainability into its product platforms for many years. Its line of 10000-series regenerative bidirectional power supplies and electronic loads have the power instrument industry’s highest efficiency with 96.5% recovery of absorbed energy returned to the AC power grid. Regenerative programmable power supplies and electronic loads reduce heat, noise, and HVAC costs. The high efficiency translates into the lowest consumption of utilities and the greatest savings of annual utility costs.

EA Elektro-Automatik bidirectional power supplies have the highest energy recovery in the industry.

Superior accuracy and stability for demanding tests

EA instruments can meet the most demanding accuracy and stability requirements for high-power testing. The major components of accuracy include display accuracy, load regulation, and temperature coefficient. EA 10000-series instruments have voltage display accuracy of 0.05% of full-scale voltage, load regulation of 0.05% of full-scale voltage and a temperature coefficient of 30 ppm/° C. Stability is essential for testing over a manufacturing work shift to ensure constant output over the required time interval. Many power instrument manufacturers do not specify stability. EA instruments do and specify 0.02% of full-scale voltage over an 8-hour interval. Tight accuracy and good stability reduce instrument variability. That translates to less uncertainty associated with product yield.

More performance and testing ability

A built-in arbitrary waveform generator in EA power instruments allows the creation of any type of waveform on a DC level. Without the use of additional instrumentation, which complicates test setups and adds cost, EA instruments can simulate devices such as batteries, fuel cells and solar cells. The instruments can also generate waveforms required by test standards such as automotive drive simulation standards and military test standards.

Most flexible automation in programmable power supplies

Unlike other power instrument manufacturers, EA instruments offer the widest range of interface options. EA instruments interface with both personal computers (PCs) and programmable logic controllers (PLCs) for manufacturing and process control. Our instruments have two built-in instrument command languages, SCPI for PC interfacing and ModBus for PLC interfacing. In addition, all EA instruments have LabView and IVI drivers, enabling control through numerous software packages and programming languages.

Built-in interfaces include USB, Ethernet, Analog, and USB Host. Optional interfaces include CAN, CANopen, RS-232, Profibus, EtherCAT, one- or two-port ModBus, one- or two-port Profinet, and one- or two-port Ethernet. These optional interfaces can be obtained with the instrument purchase or installed at a later date. They can be added or changed at the instrument’s location. Figure 2 shows the form factor for the optional interfaces.

Figure 2. An example optional interface that screws into an instrument mainframe

Certified for applications requiring strict quality and safety standards

All EA products are CE-certified, conforming to European Union safety, health, and environmental protection requirements and manufactured to ISO 9001 quality management standards. In addition, all EA products are compliant with UL and CSA standards. EA products are tested and certified by independent third-party companies to ensure compliance with various standards.

EA instrumentation: Prepared for next-generation technology

EA instrumentation offers the highest voltage and the most power to meet test requirements for future products such as electric vehicle batteries whose voltages are approaching 1000 V and capacities exceed 100 kWh. Superior accuracy and stability combined with greater functionality to simulate devices and to generate complex waveforms also ensure EA instruments are well prepared for testing advanced technology products. Their industry-leading efficiency, wide measurement range and high-density power provide capital cost savings, utility savings and space savings to justify an attractive return on investment. Contact us to learn more