お問い合わせ

ダウンロード

マニュアル、データシート、ソフトウェアなどのダウンロード:

フィードバック

TICP Series User Manual

This manual describes installing and setting up the TICP Series probes, and provides specifications and basic operations.

該当製品:

TICP025, TICP050, TICP100

By downloading, you agree to the terms and conditions of the Manuals Download Agreement.

Manuals Download Agreement

ATTENTION: please read the following terms and conditions carefully before downloading any documents from this website. By downloading manuals from Tektronix' website, you agree to the following terms and conditions:

Manuals for Products That Are Currently Supported:

Tektronix hereby grants permission and license to owners of Tektronix instruments to download and reproduce the manuals on this website for their own internal or personal use. Manuals for currently supported products may not be reproduced for distribution to others unless specifically authorized in writing by Tektronix, Inc.

A Tektronix manual may have been revised to reflect changes made to the product during its manufacturing life. Thus, different versions of a manual may exist for any given product. Care should be taken to ensure that one obtains the proper manual version for a specific product serial number.

Manuals for Products That Are No Longer Supported:

Tektronix cannot provide manuals for measurement products that are no longer eligible for long term support. Tektronix hereby grants permission and license for others to reproduce and distribute copies of any Tektronix measurement product manual, including user manuals, operator's manuals, service manuals, and the like, that (a) have a Tektronix Part Number and (b) are for a measurement product that is no longer supported by Tektronix.

A Tektronix manual may be revised to reflect changes made to the product during its manufacturing life. Thus, different versions of a manual may exist for any given product. Care should be taken to ensure that one obtains the proper manual version for a specific product serial number.

This permission and license does not apply to any manual or other publication that is still available from Tektronix, or to any manual or other publication for a video production product or a color printer product.

Disclaimer:

Tektronix does not warrant the accuracy or completeness of the information, text, graphics, schematics, parts lists, or other material contained within any measurement product manual or other publication that is not supplied by Tektronix or that is produced or distributed in accordance with the permission and license set forth above.

Tektronix may make changes to the content of this website or to its products at any time without notice.

Limitation of Liability:

TEKTRONIX SHALL NOT BE LIABLE FOR ANY DAMAGES WHATSOEVER (INCLUDING, WITHOUT LIMITATION, ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR FOR INFRINGEMENT OF INTELLECTUAL PROPERTY) ARISING OUT OF THE USE OF ANY MEASUREMENT PRODUCT MANUAL OR OTHER PUBLICATION PRODUCED OR DISTRIBUTED IN ACCORDANCE WITH THE PERMISSION AND LICENSE SET FORTH ABOVE.

Read Online

OPERATING INFORMATION

- TICP block diagram

- Measurement system handling best practices

- Environmental requirements

- Controls and indicators

- Cable flags

- Probe tips

- Ferrite clamp installation

- Connecting to a circuit

- Tripod adapter installation

- Bipod installation

- Connecting the SMA adapter

- Installing the probe tip adapters

- Installing the square pins on the circuit board

- Probe Setup menu

- Selecting a probe tip

- Deskew

- Input offset

- Voltage range

TEKTRONIX END USER LICENSE AGREEMENT

Third Party Software Licenses

This component module is generated by Processor Expert. Do not modify it. Copyright : 1997 - 2015 Freescale Semiconductor, Inc. All Rights Reserved. THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS "AS IS" AND ANY EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT HOLDER OR CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE. http: www.freescale.com mail: [email protected] IARSourceLicense.txt Version 1.0 The following license agreement applies to linker command files, example projects unless another license is explicitly stated, the cstartup code, low_level_init.c, and some other low-level runtime library files. Copyright 2012, IAR Systems AB. THE SOFTWARE IS PROVIDED "AS IS" AND THE AUTHOR DISCLAIMS ALL WARRANTIES WITH REGARD TO THIS SOFTWARE INCLUDING ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS. IN NO EVENT SHALL THE AUTHOR BE LIABLE FOR ANY SPECIAL, DIRECT, INDIRECT, OR CONSEQUENTIAL DAMAGES OR ANY DAMAGES WHATSOEVER RESULTING FROM LOSS OF USE, DATA OR PROFITS, WHETHER IN AN ACTION OF CONTRACT, NEGLIGENCE OR OTHER TORTIOUS ACTION, ARISING OUT OF OR IN CONNECTION WITH THE USE OR PERFORMANCE OF THIS SOFTWARE. Freescale Kinetis Design Studio

IAR Embedded Workbench for ARM

Important safety information

This manual contains information and warnings that must be followed by the user for safe operation and to keep the product in a safe condition.

To safely perform service on this product, see the Service safety summary that follows the General safety summary.

General safety summary

Use the product only as specified. Review the following safety precautions to avoid injury and prevent damage to this product or any products connected to it. Carefully read all instructions. Retain these instructions for future reference.

This product shall be used in accordance with local and national codes.

For correct and safe operation of the product, it is essential that you follow generally accepted safety procedures in addition to the safety precautions specified in this manual.

The product is designed to be used by trained personnel only.

Only qualified personnel who are aware of the hazards involved should remove the cover for repair, maintenance, or adjustment.

Before use, always check the product with a known source to be sure it is operating correctly.

This product is not intended for detection of hazardous voltages.

Use personal protective equipment to prevent shock and arc blast injury where hazardous live conductors are exposed.

While using this product, you may need to access other parts of a larger system. Read the safety sections of the other component manuals for warnings and cautions related to operating the system.

When incorporating this equipment into a system, the safety of that system is the responsibility of the assembler of the system.

To avoid fire or personal injury

Observe all terminal ratings

To avoid fire or shock hazard, observe all rating and markings on the product. Consult the product manual for further ratings information before making connections to the product.

Do not exceed the Measurement Category (CAT) rating and voltage or current rating of the lowest rated individual component of a product, probe, or accessory.

Do not apply a potential to any terminal, including the common terminal, that exceeds the maximum rating of that terminal.

The measurement terminals on this product are not rated for connection to Category IV circuits.

Do not connect a current probe to any wire that carries voltages above the current probe voltage rating.

Do not operate without covers

Do not operate this product with covers or panels removed, or with the case open. Hazardous voltage exposure is possible.

Avoid exposed circuitry

Do not touch exposed connections and components when power is present.

Do not operate with suspected failures

If you suspect that there is damage to this product, have it inspected by qualified service personnel.

Disable the product if it is damaged. Do not use the product if it is damaged or operates incorrectly. If in doubt about safety of the product, turn it off. Clearly mark the product to prevent its further operation.

Before use, inspect voltage probes, test leads, and accessories for mechanical damage and replace when damaged. Do not use probes or test leads if they are damaged, if there is exposed metal, or if a wear indicator shows.

Examine the exterior of the product before you use it. Look for cracks or missing pieces.

Use only specified replacement parts.

Do not operate in wet/damp conditions

Be aware that condensation may occur if a unit is moved from a cold to a warm environment.

Do not operate in an explosive atmosphere

Keep product surfaces clean and dry

Remove the input signals before you clean the product.

Provide a safe working environment

Always place the product in a location convenient for viewing the display and indicators.

Avoid improper or prolonged use of keyboards, pointers, and button pads. Improper or prolonged keyboard or pointer use may result in serious injury.

Be sure your work area meets applicable ergonomic standards. Consult with an ergonomics professional to avoid stress injuries.

Probes and test leads

| WARNING:To avoid electric shock, keep the probe wire as far from the tip and high voltage circuits as possible. The probe wire voltage rating is less than the probe tip voltage rating. Therefore the probe wire may not provide adequate protection. |

| WARNING:To avoid electric shock, do not use the probe if the wear indicator on the cable becomes visible. Contact Tektronix at tek.com for a replacement. |

Beware of high voltages

Understand the voltage ratings for the probe you are using and do not exceed those ratings. Two ratings are important to know and understand:

- The maximum measurement voltage from the probe tip to the probe reference lead.

- The maximum floating voltage from the probe reference lead to earth ground.

These two voltage ratings depend on the probe and your application. Refer to the Specifications section of the manual for more information.

| WARNING:To prevent electrical shock, do not exceed the maximum measurement or maximum floating voltage for the oscilloscope input BNC connector, probe tip, or probe reference lead. |

Connect and disconnect properly.

Do not connect or disconnect probes or test leads while they are connected to a voltage source.

Use only insulated voltage probes, test leads, and adapters supplied with the product, or indicated by Tektronix to be suitable for the product.

De-energize the circuit under test before connecting or disconnecting the current probe.

Do not connect a current shunt to any wire that carries voltages or frequencies above the current shunt voltage rating

Inspect the probe and accessories

Before each use, inspect probe and accessories for damage (cuts, tears, or defects in the probe body, accessories, or cable jacket). Do not use if damaged.

Floating measurement use

Do not float the reference lead of this probe above the rated float voltage.

Service the probe and accessories

Go to tek.com/support to find information on contacting Tektronix Service Support.

Terms in this manual and on the product

These terms may appear in this manual:

| WARNING:Warning statements identify conditions or practices that could result in injury or loss of life. |

| CAUTION:Caution statements identify conditions or practices that could result in damage to this product or other property. |

These terms may appear on the product:

- DANGER indicates an injury hazard immediately accessible as you read the marking.

- WARNING indicates an injury hazard not immediately accessible as you read the marking.

- CAUTION indicates a hazard to property including the product.

Symbols on the product

|

| When this symbol is marked on the product, be sure to consult the manual to find out the nature of the potential hazards and any actions which have to be taken to avoid them. (This symbol may also be used to refer the user to ratings in the manual.) |

The following symbols(s) may appear on the product.

CAUTION: Refer to Manual |  Protective Ground (Earth) Terminal |  Earth Terminal |

WARNING: High Voltage |  Connection and disconnection to hazardous bare wire permitted. |  Do not connect to or remove from an uninsulated conductor that is HAZARDOUS LIVE. |

WARNING: Hot Surface |

Clearance requirements

The unique common mode voltage range of the measurement system allows it to be used in the presence of high frequency/high voltage common mode signals. It is important to observe all precautions while using this product.

| WARNING:Electrical shock can occur while using this measurement system. The system is intended to isolate the operator from hazardous input voltages (common mode voltages); the plastic case of the probe head and the shield on the probe tip do not supply safe isolation. Maintain the safe clearance from the probe head and probe tip while the measurement system is connected to the energized circuit as recommended in this document. Do not access the RF Burn Hazard Zone while taking measurements on a live circuit. |

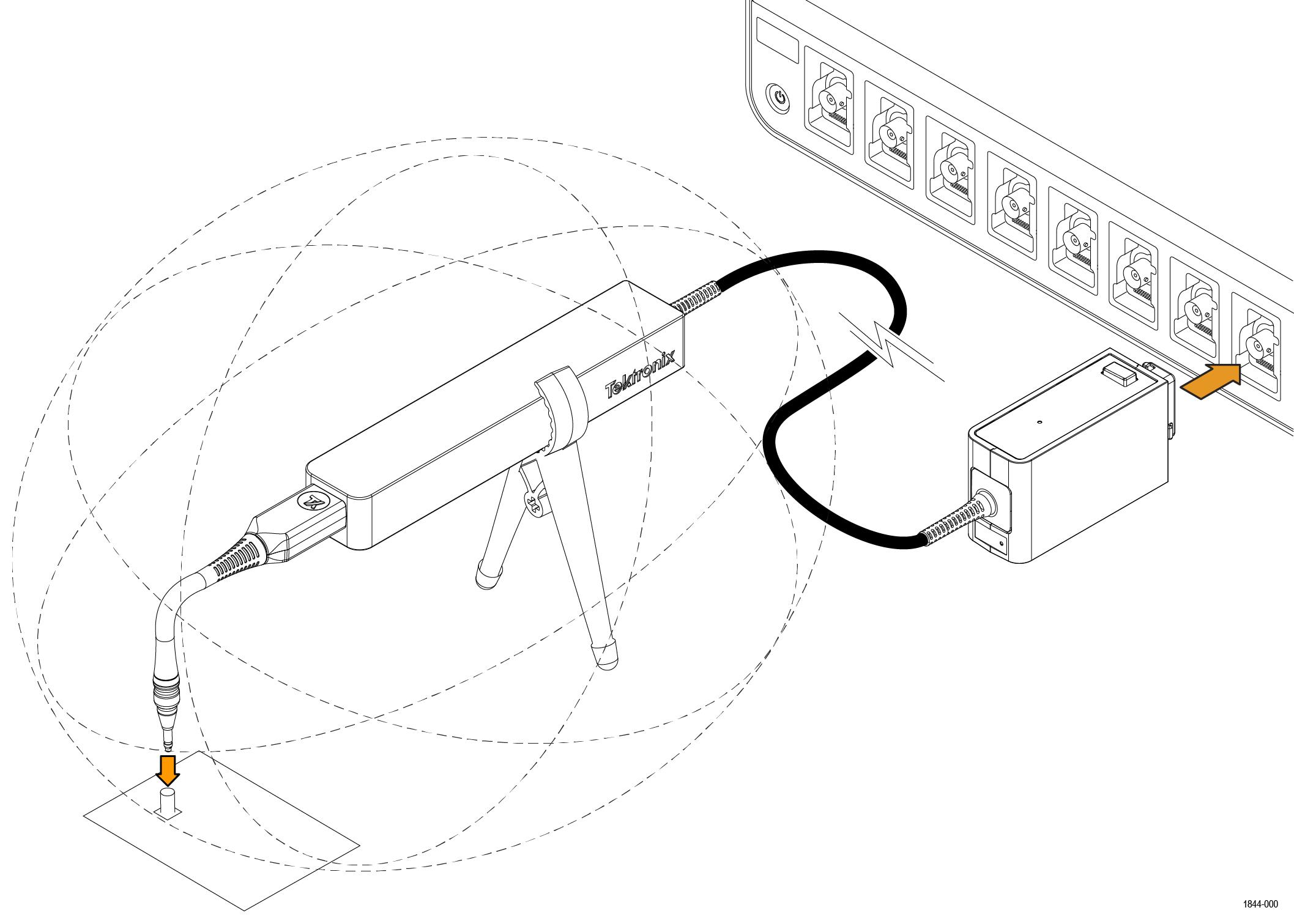

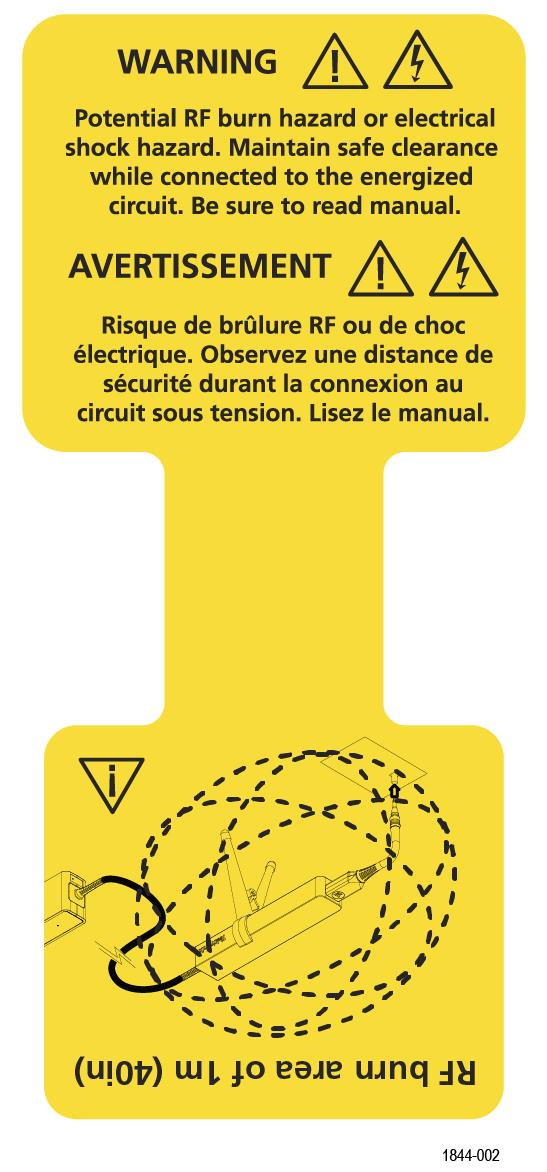

The following figure shows the components of the measurement system and the potential RF burn area when working with hazardous voltages. The RF burn area of 1 m (40 in.) is indicated by the dashed lines surrounding the probe head.

| WARNING: Risk of RF burns. Refer to the following derating curve to identify the danger areas. To avoid RF burns, do not operate the probe within limits of the gray shaded area in the graph. |

| WARNING: There is a risk of burn from elevated temperatures on the tip when continuous wave or high duty cycle burst common mode signals are between about 10 MHz and 50 MHz. This causes the tip ferrites to dissipate significant power at voltages lower than found on the following graph. To avoid the burn risk, keep the tip temperature at 85°C (185°F) or lower by limiting the applied common mode voltage and/or duty cycle, lowering the ambient temperature, and/or applying forced convection airflow. |

Compliance information

This section lists the safety and environmental standards with which the instrument complies. This product is intended for use by professionals and trained personnel only; it is not designed for use in households or by children.

Compliance questions may be directed to the following address:

Tektronix, Inc.

PO Box 500, MS 19-045

Beaverton, OR 97077, US

tek.com

Safety compliance

This section lists the safety standards with which the product complies and other safety compliance information.

EU declaration of conformity – low voltage

Compliance was demonstrated to the following specification as listed in the Official Journal of the European Union:

Low Voltage Directive 2014/35/EU.

- EN 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part 1: General Requirements

- EN 61010-2-030. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part 2-030: Particular requirements for testing and measuring circuits

U.S. nationally recognized testing laboratory listing

- UL 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part 1: General Requirements

- UL 61010-2-030. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part 2-030: Particular requirements for testing and measuring circuits

Canadian certification

- CAN/CSA-C22.2 No. 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part 1: General Requirements

- CAN/CSA-C22.2 No. 61010-2-030. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part 2-030: Particular requirements for testing and measuring circuits

Additional compliances

- IEC 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part 1: General Requirements

- IEC 61010-2-030. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part 2-030: Particular requirements for testing and measuring circuits

Equipment type

Test and measuring equipment.

Pollution degree description

A measure of the contaminants that could occur in the environment around and within a product. Typically the internal environment inside a product is considered to be the same as the external. Products should be used only in the environment for which they are rated.

- Pollution Degree 1. No pollution or only dry, nonconductive pollution occurs. Products in this category are generally encapsulated, hermetically sealed, or located in clean rooms.

- Pollution Degree 2. Normally only dry, nonconductive pollution occurs. Occasionally a temporary conductivity that is caused by condensation must be expected. This location is a typical office/home environment. Temporary condensation occurs only when the product is out of service.

- Pollution Degree 3. Conductive pollution, or dry, nonconductive pollution that becomes conductive due to condensation. These are sheltered locations where neither temperature nor humidity is controlled. The area is protected from direct sunshine, rain, or direct wind.

- Pollution Degree 4. Pollution that generates persistent conductivity through conductive dust, rain, or snow. Typical outdoor locations.

IP rating

IPx0 (as defined in IEC 60529).

Electrical ratings

- Electrical ratings

- TICP025: Current 20mA, 250MHz

- Max voltage to Earth

- 1300 V; Pollution degree 2; Max with transient level not to exceed 5kVpk

Environmental compliance

This section provides information about the environmental impact of the product.

Product end-of-life handling

Observe the following guidelines when recycling an instrument or component:

- Equipment recycling

- Production of this equipment required the extraction and use of natural resources. The equipment may contain substances that could be harmful to the environment or human health if improperly handled at the product’s end of life. To avoid release of such substances into the environment and to reduce the use of natural resources, we encourage you to recycle this product in an appropriate system that will ensure that most of the materials are reused or recycled appropriately.

|

This symbol indicates that this product complies with the applicable European Union requirements according to Directives 2012/19/EU and 2006/66/EC on waste electrical and electronic equipment (WEEE) and batteries. For information about recycling options, check the Tektronix Web site (http://www.tek.com/productrecycling). |

Preface

This document provides information for installing and using the Tektronix TICP Series Active Isolated Current Shunt Probes.

The probe provide unparalleled bandwidth, accuracy, ease of use, and isolation in current shunt measurements.

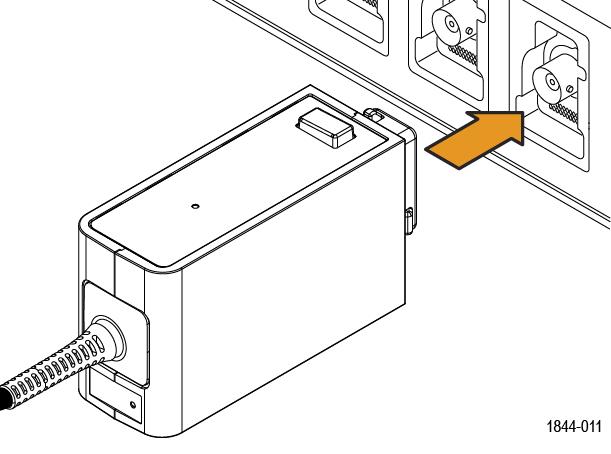

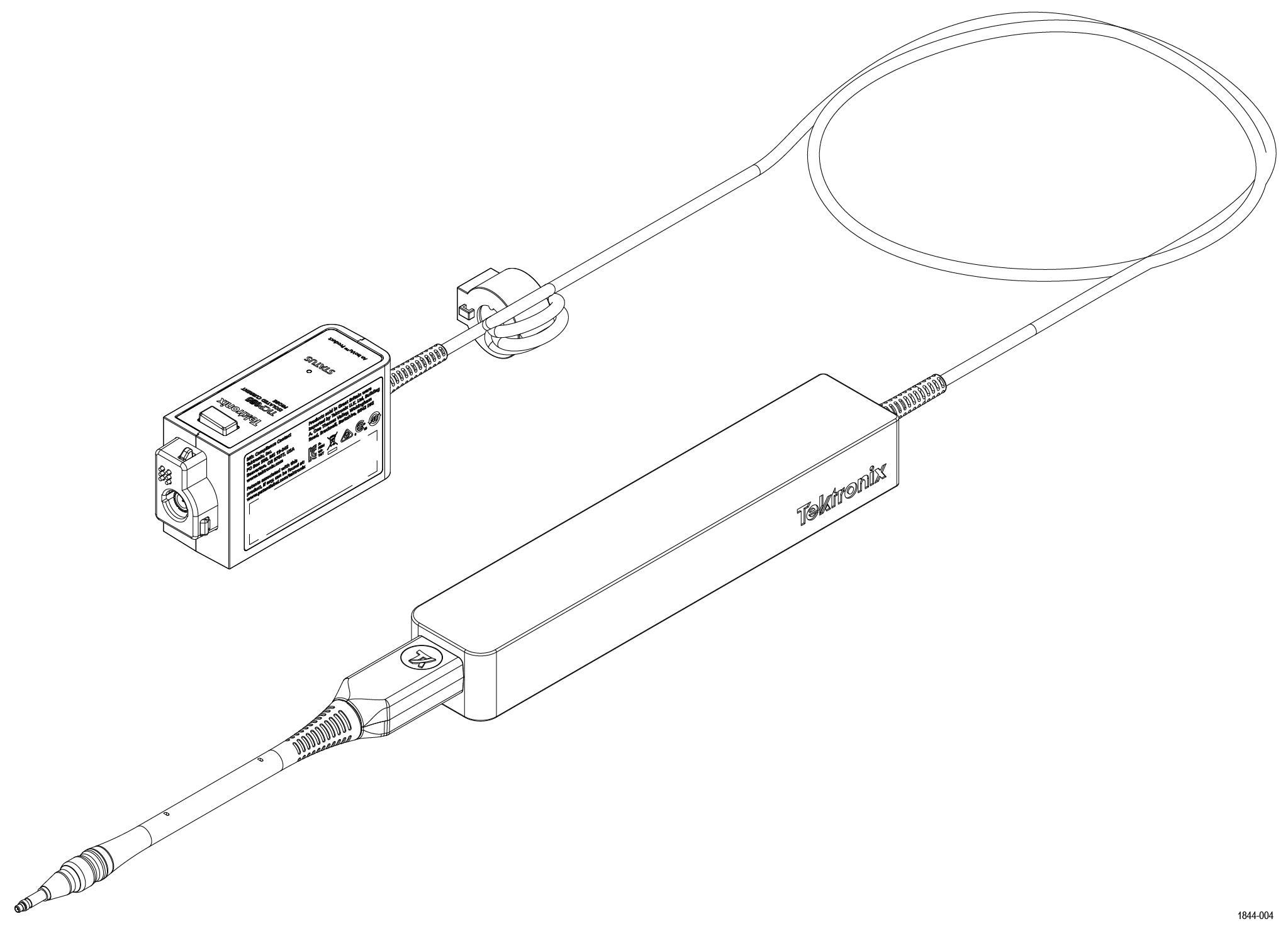

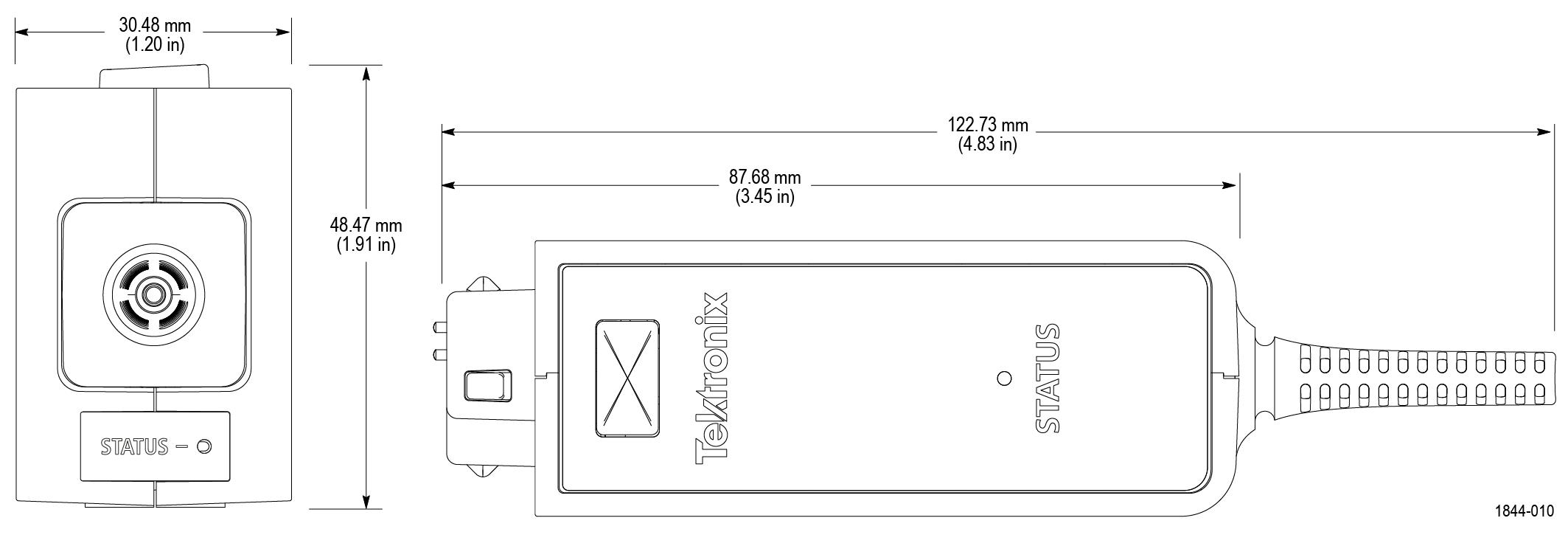

Compensation box

The TekVPI compensation (comp) box connects the measurement system to one of the input channels on the oscilloscope. Power is supplied to the measurement system through the TekVPI interface of the oscilloscope. The LEDs on the comp box provide a means for indicating the overall status of the probe.

Probe head

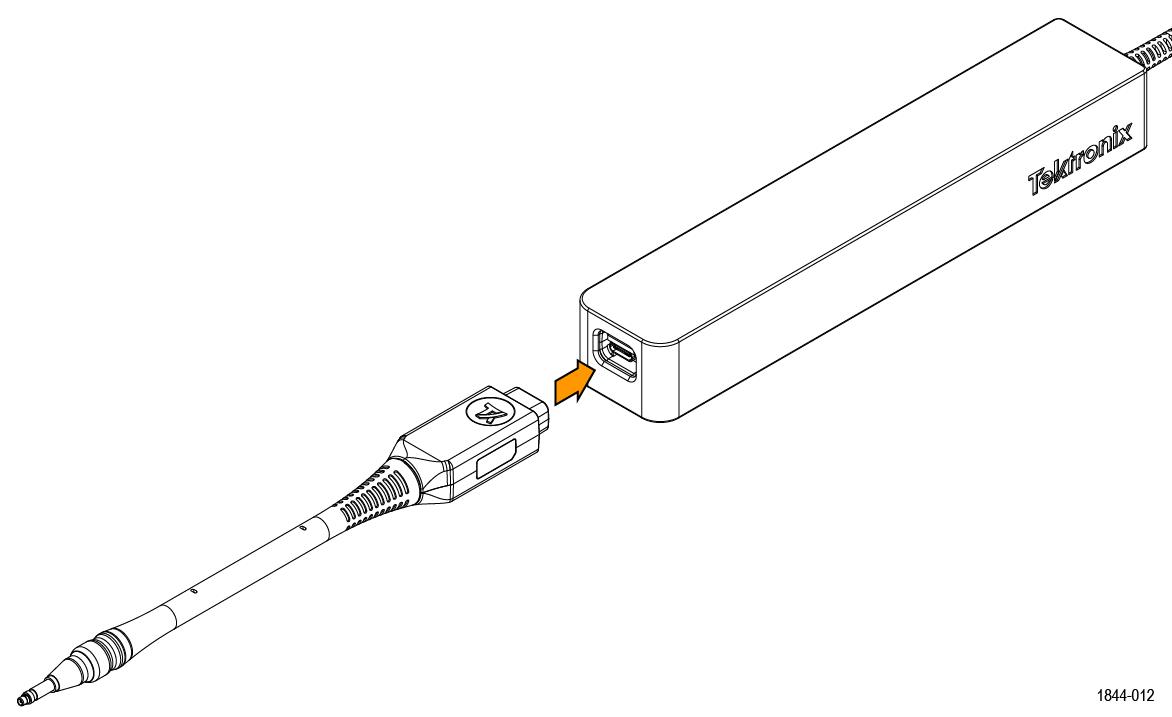

The probe head provides an interface between the device-under-test (DUT) and the compensation box. The probe head contains the isolation barrier that separates the DUT from the earth ground.

Probe tips

Probe tip options are available to connect the probe head to the DUT.

Key performance specifications and features

- Galvanic isolation between probe tip and the oscilloscope

- Available in three bandwidths: 1 GHz, 500 MHz, and 250 MHz

- Wide current measurement range determined by the shunt used with 1X, 10X or 100X probe tips

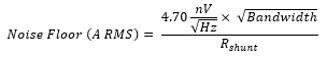

- Noise <4.70 nV / √Hz (<21 μVRMS at 20 MHz)

- Up to 90 dB CMRR at 1 MHz

- Maximum common mode voltage: 1.8 kV; For use in a Pollution Degree 1 environment; transient level not to exceed 5 kVpk

- 1.5% DC gain accuracy

- Compatible with the 4, 5, and 6 Series MSO instruments, including the latest B models

- TekVPI™ interface enables control and probe configuration from the oscilloscope front panel or programming interface

Model overview

Standard accessories

The following table lists the accessories that are shipped with the probe.

| Accessory | Description | Part number |

|---|---|---|

|

| 1X probe tip cable with MMCX connector | TICPMM1 |

|

| 10X probe tip cable with MMCX connector | TICPMM10 |

| SMA tip adapter | TICPSMA |

| Clamp-on ferrite common mode choke | 276-0905-XX |

| Bipod is used to hold the probe. | 020-3210-XX |

| Tripod adapter for ¼ in - 20 UNC thread accessories. | 103-0508-XX |

| Probe tip adapter. Adapts an MMCX IsoVu tip to standard 0.100" spaced, 0.025" square pins. | 131-9717-XX |

| Soft carrying case with foam insert. | 016-2147-XX |

Recommended accessories

The following table lists optional accessories.

| Accessory | Description | Part number |

|---|---|---|

|

| 100X probe tip with MMCX connector | TICPMM100 |

| Square pin to MMCX adapter, 0.062" spacing | 131-9677-XX |

|

| MMCX to IC grabber lead | 196-3546-XX |

|

| Square pin to IC grabber lead | 196-3547-XX |

| MicroCKT grabbers | 206-0569-XX |

Operating information

Use this section to help you use the probe safely and effectively. Read all safety information before installing your measurement system to be aware of the operating and clearance requirements, including possible hazardous areas when the measurement system is connected to the DUT.

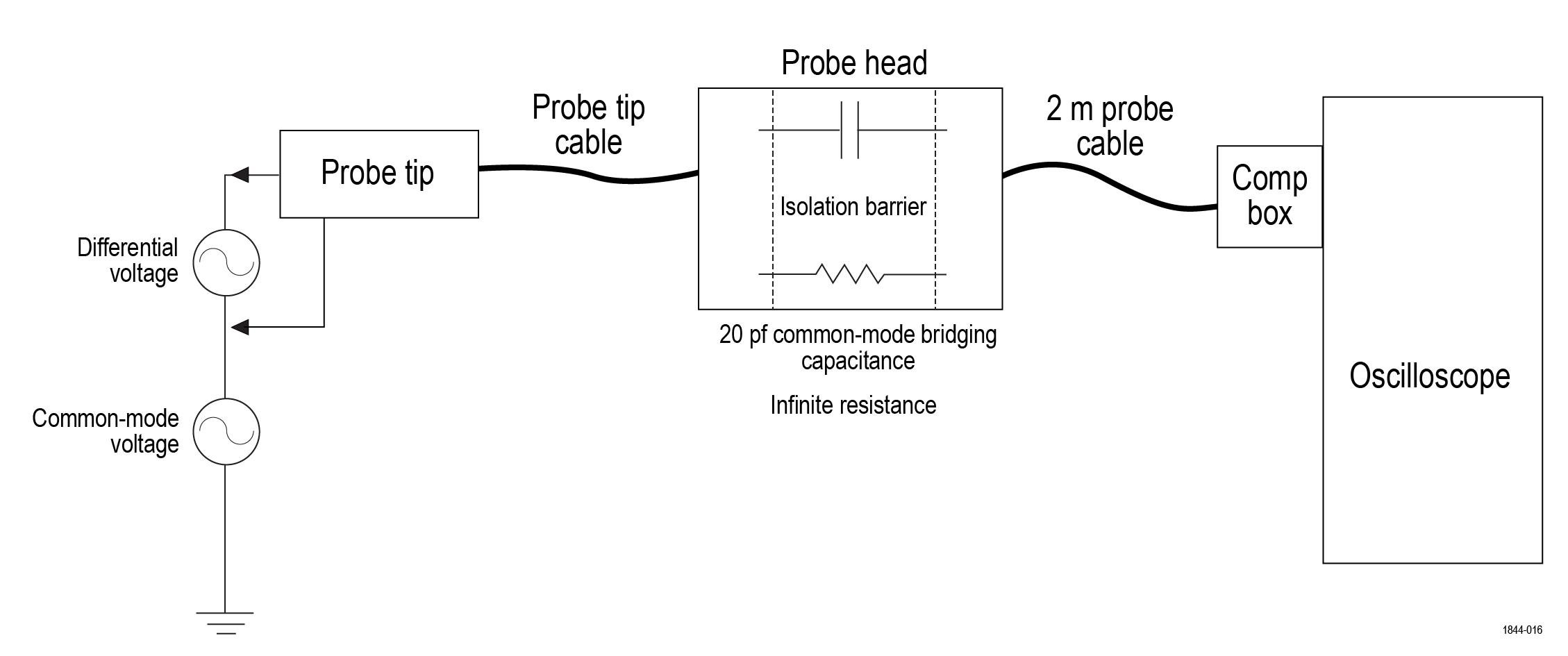

TICP block diagram

The following figure shows a block diagram of the Tektronix Active Isolated Current Shunt Probe.

The common-mode resistance and capacitance to earth ground is shown in the figure. The common-mode resistance is shown as infinite with the probe since it is galvanically isolated and can be ignored. The common-mode coupling capacitance to earth ground and the surrounding circuit is shown as the bridging capacitance. This capacitance will be approximately 20 pF when the probe head is placed 6 inches (15.25 cm) above a ground plane.

- When possible, choose a reference point in the device-under-test (DUT) that is static potential with respect to earth ground.

- Connect the coaxial (common) shield of the probe tip to the lowest impedance point of the circuit.

- Increasing the physical distance between the probe head and any conductive surface will reduce the capacitance.

- When using multiple TICP probes to measure different points in the circuit that do not have the same common-mode voltages, keep the probe heads separated to minimize the capacitive coupling.

Measurement system handling best practices

The measurement system consists of quality parts and should be treated with care to avoid damage or degrading the performance due to mishandling. Consider the following precautions when handling the probe and tips.

- Do not crush, crimp, or sharply bend the probe cable..

- Do not twist the cable.

- Do not allow kinks or knots to develop in the probe cable.

- Avoid putting tension on the probe cable.

- Do not pull or jerk the cable, especially when kinks or knots are present.

- Do not drop the probe head or comp box assembly. This can result in damage and misalignment of the internal components.

- Avoid over-bending the probe tips; do not exceed the minimum bend radius of 2.0 inches (5.1 cm).

- Avoid crushing the cables by accidentally running over the cable with a chair wheel or by dropping a heavy object onto the cable.

- Store the measurement system in the supplied carrying case when not in use.

Environmental requirements

| Characteristic | Component | Operating | Non-operating |

|---|---|---|---|

| Temperature | Compensation box and probe head | 0°C to +50°C | -20°C to +70°C |

| Tip cables and adapters | -40°C to +85°C | -40°C to +85°C | |

| Humidity | Compensation box and probe head | 5% to 85% relative humidity up to +40°C, 5% to 45% relative humidity up to +50°C, non-condensing | 5% to 85% relative humidity up to +40°C, 5% to 45% relative humidity up to +70°C, non-condensing |

| Tip cables and adapters | |||

| Altitude | All components | Up to 3,000 meters (9,842 feet) | Up to 12,000 meters (39370 feet) |

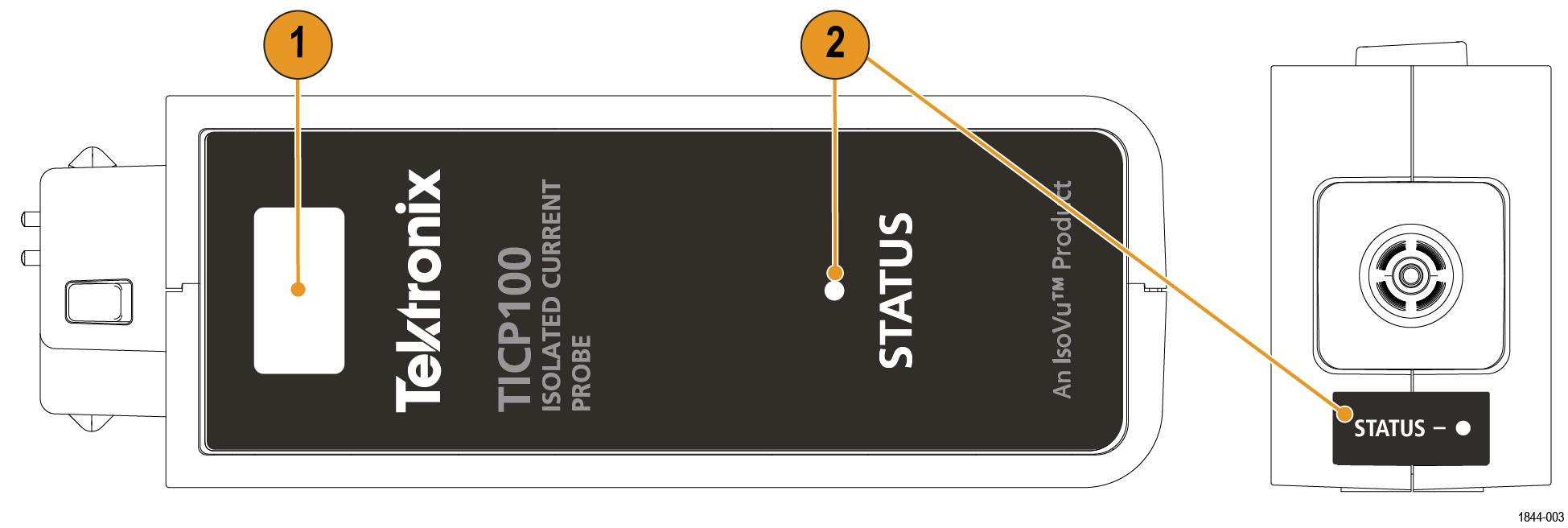

Controls and indicators

A description of the controls and indicators on the compensation box.

- Latch release button. To disconnect the compensation (comp) box from the oscilloscope, press the latch release button and pull away from the instrument.

- STATUS indicators. LED lights that indicates the status of the probe. There is a status indicator on the top and back of the comp box. For more information on the state of the LED, see Table 1

Cable flags

The flag on the cable provide a potential RF burn hazards warning.

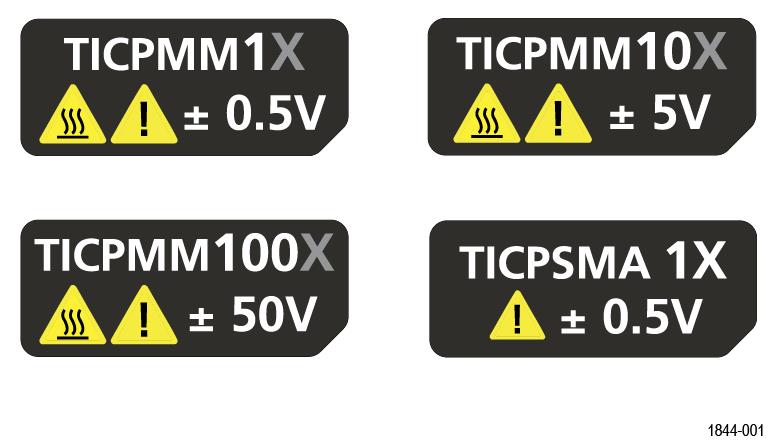

Probe tips

Each probe tip has a label that provides the maximum dynamic range and displays the attenuation factor.

Ferrite clamp installation

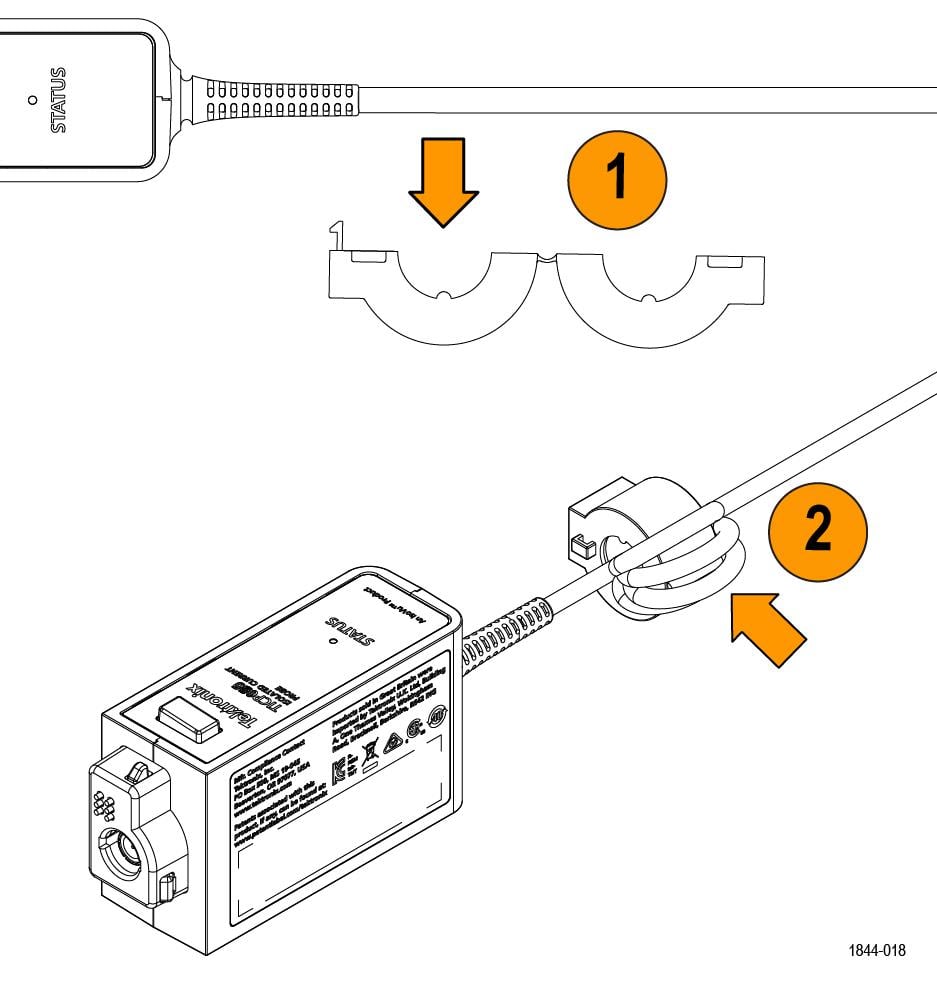

The following steps describe installing the common mode ferrite clamp on the probe cable.

Procedure

What to do next

Connecting to a circuit

The following steps describe the process for connecting the TICP Series probe to an oscilloscope and the device under test (DUT).

Before you begin

| WARNING:Do not connect the measurement system to an energized circuit to avoid the risk of shock. Always de-energize the circuit-under-test before installing or removing the tip cable from the circuit-under-test. The plastic case of the probe head and the probe tip of the probe cable do not supply the isolation. |

| WARNING:To avoid the risk of electrical shock or RF burns while the DUT is energized, do not touch the probe head or probe tip while taking measurements. Always keep a 1 m (40 in.) clearance from the probe head during the measurement. See Figure 1. |

| WARNING:To prevent the arc flash caused by a different potential, do not place the probe head or probe tip on the circuit that has the different voltage. |

| CAUTION:To avoid possible damage to the equipment, do not connect the coaxial (common) shield of the probe tip or SMA input to the high impedance portion of a circuit. The additional capacitance can cause circuit damage. Connect the coaxial (common) shield to the low impedance section of the circuit. |

| Note:Touching the probe head or probe tip cable when measuring a high frequency common mode signal increases the capacitive coupling and can degrade the common mode loading on the circuit-under-test. |

| Note:To avoid inaccurate measurements, do not stack the separate probe heads and keep cell phones at least three feet away while taking measurements. |

About this task

Verify the DUT is not connected to an energized circuit. To obtain the most accurate measurement, allow the probe to warm up for 5 minutes.

Procedure

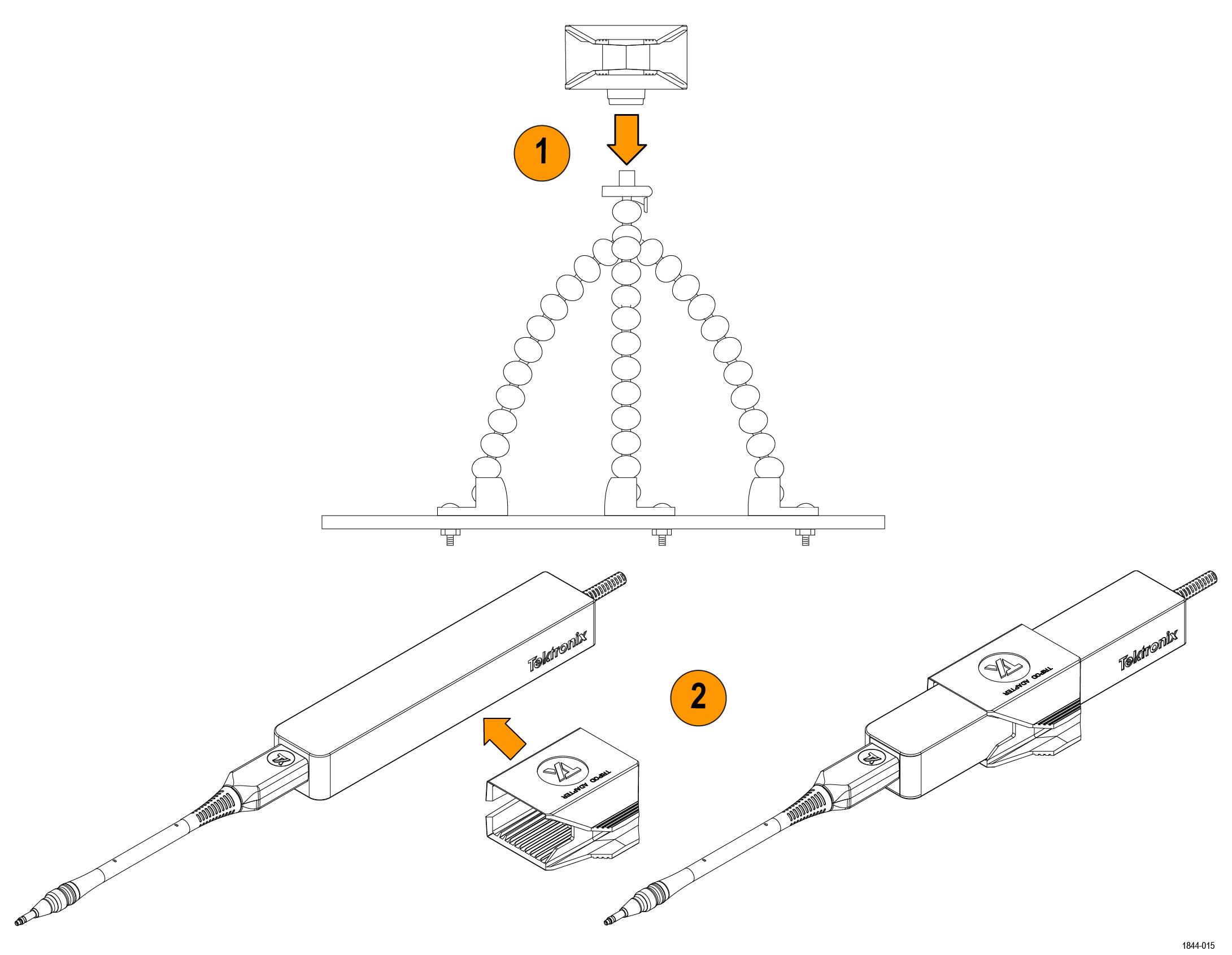

Tripod adapter installation

The following steps describe installing the tripod adapter to the probe head and attaching it to a tripod.

Procedure

Bipod installation

The following steps describe installing the bipod to the probe head.

Procedure

- Squeeze the handles of the bipod together to open the clamp.

- Place the probe head into the clamp and release the handle so the probe is as the angle needed to connect to the DUT.

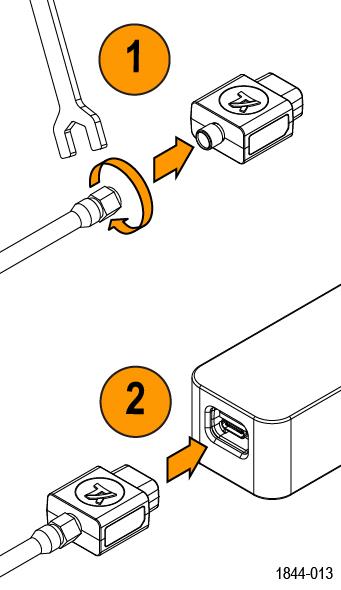

Connecting the SMA adapter

The following steps describe the process for connecting the TICPSMA SMA tip adapter to the probe head and SMA cable.

Before you begin

| Note:It recommended to connect SMA cable to the SMA adapter first and then connect the SMA adapter to the probe head. |

Procedure

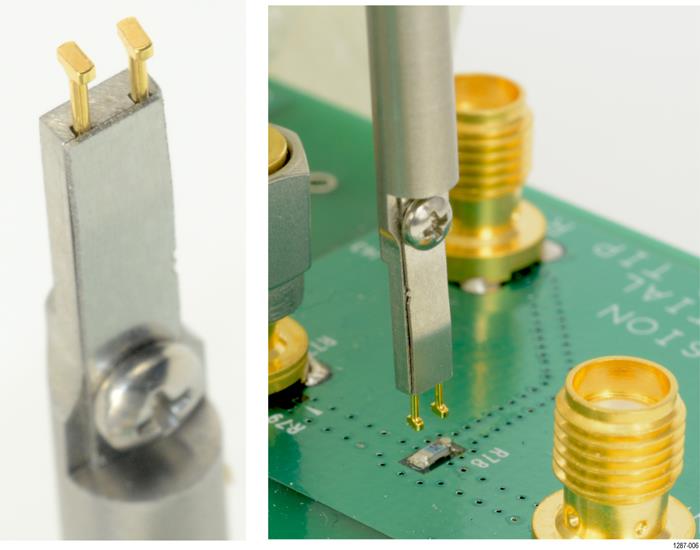

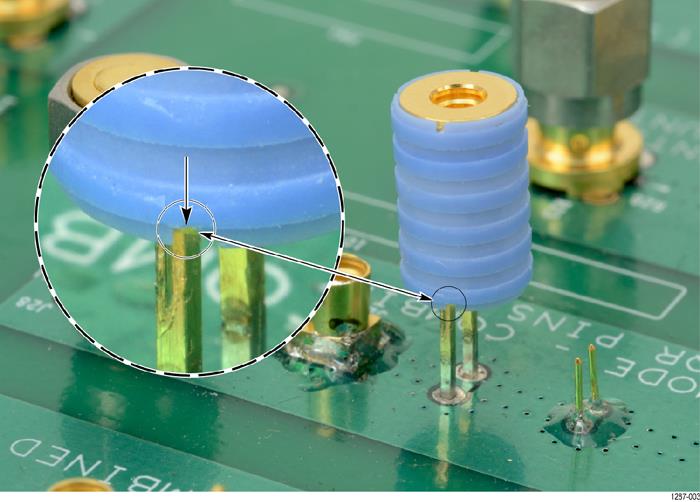

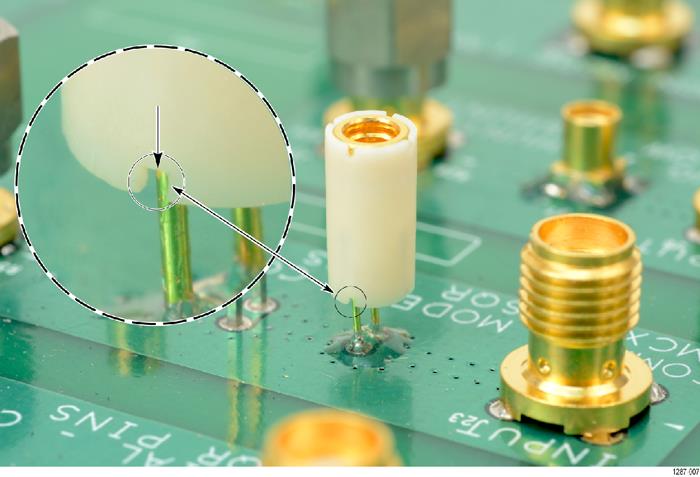

Installing the probe tip adapters

There are two Tektronix probe tip adapters to connect the MMCX probe tips to pins on the circuit board. The MMCX-to-0.1-inch (2.54 mm) pitch adapter and the MMCX-to-0.062-inch (1.57 mm) pitch adapter.

One end of each adapter has an MMCX socket for connection to an IsoVu MMCX tip cable. The other end of the adapter has a center pin socket and four common (shield) sockets around the outside of the adapter. Notches on the adapters can be used to locate the shield sockets. The procedure for installing these adapters are the same, the main difference is the spacing of the pins on the circuit board.

To install the adapters onto the square pins, line up the center of the adapter with the signal source pin on the circuit board. Use the notch on the adapter to align one of the shield sockets to the common pin on the circuit board. The following figures show examples of lining up the adapters on the circuit board.

To achieve the best electrical performance, especially the CMRR performance and EMI susceptibility, place the probe tip adapter as close as possible to the circuit board.

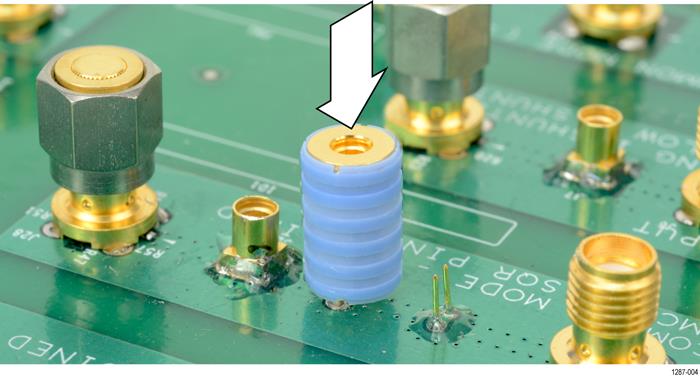

After lining up the adapters gently push down on the adapter to seat it in place on the circuit board.

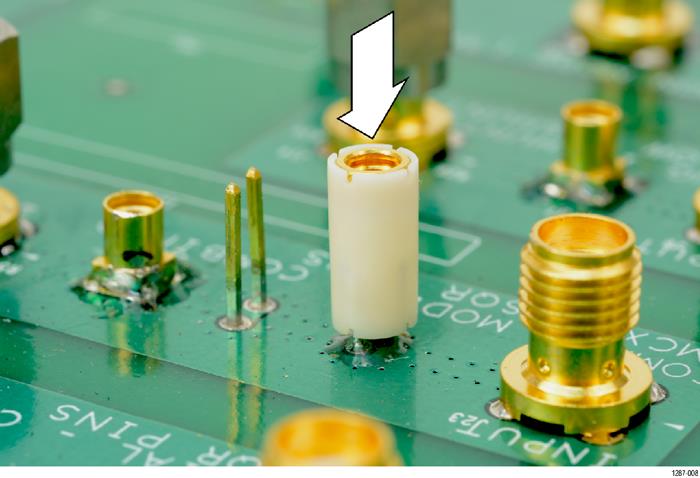

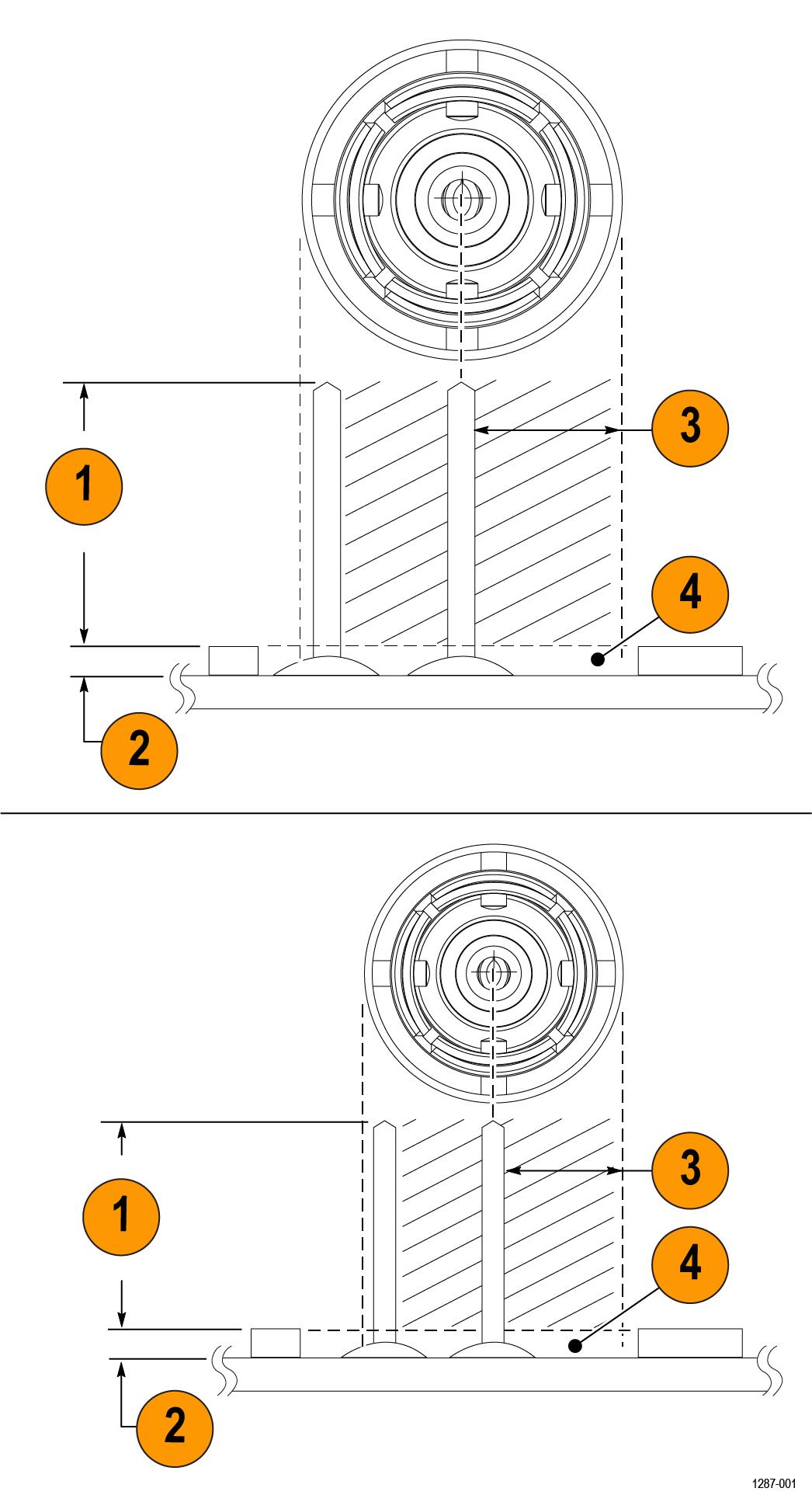

Installing the square pins on the circuit board

The following figure and table shows the recommended clearance requirements for connecting the adapters to the square pins on the circuit board. The bottoms of the adapters are shown at the top.

| Figure reference | Probe Tip Adapter, MMCX to 0.1” pitch sq. pin 0.635 mm (0.025 in) sq. pins | Probe Tip Adapter, MMCX to 0.062 in pitch sq. pin 0.406 mm (0.016 in) sq. pins |

|---|---|---|

| 1 | Recommend maximum pin length 6.00 mm (0.235 in) | Recommend maximum pin length 4.40 mm (0.170 in) |

| 2 | Minimize area between adapter and circuit board | |

| 3 | Keep out area (diameter of each adapter) | |

| 4 | Avoid or minimize components within keep out area | |

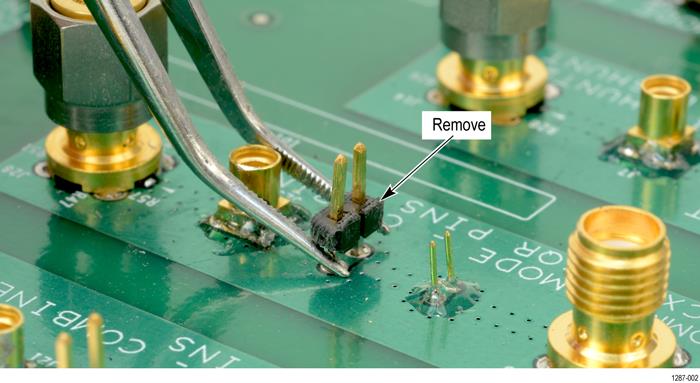

The 0.025-inch (0.635 mm) square pins should already be located on the circuit board. Some square pins might have headers installed on the circuit board. Tektronix recommends removing the plastic spacer from the square pins to gain closer access to the circuit board as shown in the following figure to achieve the best electrical performance, especially CMRR. You might need to use a pair of tweezers to remove the spacer as shown in the figure.

Tektronix provides a set of solder pins (0.018-inch (0.46 mm) diameter) to install on the circuit board for use with the MMCX to 0.062-inch (1.57 mm) adapter. Use the soldering aide tool accessory (Tektronix part number, 003-1946-xx) to install these pins on the circuit board.

The solder pins are extremely small and can be challenging to handle. Tektronix recommends using tweezers and a magnifying tool when installing the pins on the circuit board.

The solder pins can be installed around a surface mounted component on the circuit board, but adequate clearance should be maintained for a good electrical connection for the adapter. Figure 1

| Note:The coaxial (common) shield of the probe tip and tip adapters should always be connected to the lowest impedance point (usually a circuit common or power supply rail) in the circuit-under-test (relative to the probe tip cable/center conductor) to obtain the most accurate waveform. |

Use the following steps to install the solder pins using the soldering aide on the circuit board:

- Carefully insert the solder pins into the soldering aide as shown in the following illustration.

Figure 3. Using the soldering aide to install the square pins on the circuit board

- Use the soldering aide to hold the square pins in place while soldering the square pins to the circuit board.

- If necessary apply a small amount of adhesive to further strengthen the connection to the circuit board. However, keep the height of the adhesive to a minimum to provide good electrical contact for the adapter. Figure 1

Probe Setup menu

Use the probe setup menu to see probe information, perform self-calibration (SelfCal), perform AutoZero, change the range mode, and configure the range.

To access the Probe Setup menu on the oscilloscope, double-tap the corresponding analog channel badge on the settings bar and tap Probe Setup.

You will receive a warning message if you connect the probe to the oscilloscope without a probe tip attached. The following images display the menu with and without the tip warning.

Self-calibration

The self-calibration (SelfCal) function that corrects gain accuracy and DC offset. These parameters change as the probe warms up to the operating temperature and remain constant once the temperature reaches steady-state.

Check the SelfCal Status in the Probe Setup menu. The status indicates when SelfCal has Passed, Failed or if it is Recommended to run SelfCal.

To check the status of the SelfCal remotely, use the SELFCAL:STATE? PI command to determine self-calibration is RECOMMENDED, RUNNING, or PASSED.

- Tap the channel badge corresponding to the channel you connected the probe to.

- In the channel menu, expand the Probe Setup tab.

- Tap the SelfCal button.

To run the self-calibration remotely, use the CH<x>:PROBE:SELFCAL EXECUTE PI command. The connected channel is specified by "x".

| Note:For the best results, run self-calibration while the probe is connected to the powered down DUT. |

When using vertical scales of 10 mV/div or less, probe self-calibration should be run with the probe tip still attached and with no signal applied to the probe tip. Additionally, for the TICPSMA and TICPMX1X tips, it is recommended to leave a representative drive impedance (a powered-down DUT) connected to the probe tip during self-calibration.

At higher vertical scales, or in the particular use case of a TICPSMA or TICPMX1X tip driven by a very low impedance (a shunt resistor ≤5 Ω), an alternate approach of disconnecting the tip from the probe head may be used to insure no signal is applied during self-calibration.

The TICP Series probe takes five minutes to warm up and self-calibration takes less than two minutes to complete. The SelfCal Status will change to Passed or Failed.

AutoZero

AutoZero and self-calibration work on different parts of the measurement system. Self-calibration optimizes measurements through adjusting parameters in the probe. AutoZero is an oscilloscope function and is used when a displayed waveform is not centered correctly (for example; due to a small DC offset error). AutoZero automatically runs after self-calibration.

It is important to power-down the DUT or disconnect your probe from the DUT before running AutoZero.

Auto Range

The Range Mode is selectable for either Auto or Manual. When the Range Mode set to Auto, the probe range is automatically selected when the V/div knob on the oscilloscope is turned. The relationship between probe range and V/div setting matches that shown in Ranges and 4/5/6 Series MSO Volts/div settings table.

Ranges

The measurement system has a variety of ranges available for you to select, whether the probe is being used with or without a tip. This allows for tradeoffs to be made between noise and dynamic range depending on the needs of the measurement being made.

| CAUTION:To avoid damaging the probe, do not exceed the Peak Voltage rating for a given tip or the probe head. The Maximum Non-Destruct Voltage limit (Peak Voltage) does not increase when the Probe Ranges are changed. |

In 4, 5, and 6 Series MSO Instruments, the ranges are selectable when Range Mode is set to Manual. The recommended V/div settings are displayed in the table below. The ranges shown are for the probe SMA input and 1X tip. Multiply the range and V/div setting by the tip attenuation to get the values for a probe tip.

| 4/5/6 Series MSO probe ranges | Recommended V/div setting |

|---|---|

| 20 mV | 2 mV/div |

| 30 mV | 5 mV/div |

| 45 mV | 5 mV/div |

| 65 mV | 10 mV/div |

| 90 mV | 10 mV/div |

| 125 mV | 20 mV/div |

| 175 mV | 20 mV/div |

| 250 mV | 20 mV/div |

| 350 mV | 50 mV/div |

| 500 mV | 100 mV/div |

When using a tip, the label of each probe tip shows the maximum dynamic range and the attenuation factor. When more sensitive ranges are selected, dynamic range is limited. Refer to the Linear differential input voltage range in the specifications table for more information.

Selecting a probe tip

| CAUTION:Avoid over-voltage conditions that can damage or degrade the probe head input termination by selecting the correct probe tip. Selecting the correct probe tip attenuation factor is crucial to ensure that the probe head input termination is not degraded or damaged by an over-voltage condition. Select the probe tip that will provide the lowest attenuation possible for the signal being measured. |

When selecting a probe tip for a particular application, consider the following questions:

- What is the maximum RMS/Peak Voltage at the test point being measured (for example, under a fault condition)?

- What is the minimum single-ended input resistance that my circuit can tolerate?

- How large of a signal do I want to display at one time on the oscilloscope?

- What sensitivity do I need (for example, the minimum V/div setting)?

The following table will help you select the correct probe tip. Start at the top of the table and work down. Choose the first tip that meets all of your criteria.

| Probe tip | Most sensitive V/div setting | Dynamic range | Maximum non-destruct voltage (DC + pk AC) | Single-ended input resistance |

|---|---|---|---|---|

| TICPSMA | 1 mV | ±0.5 V | ±3 V | 50 Ω |

| TICPMM1 | 1 mV | ±0.5 V | ±3 V | 50 Ω |

| TICPMM10 | 10 mV | ±5V | ±15 V | 500 Ω |

| TICPMM100 | 100 mV | ±50 V | ±60 V | 5000 Ω |

For maximum non-destruct voltage refer to the Maximum differential input voltage vs frequency derating graphs.

Deskew

Each probe comes loaded with nominal propagation delay values that can be automatically applied through the Vertical menu on the oscilloscope. Deskew accuracy can be improved using a known signal and a deskew fixture. When the timing relationships between waveforms is critical, always deskew your test system with known equipment.

Input offset

The measurement system provides an adjustable input referred offset voltage.

This enables viewing a portion of the signal that is off-screen or examining sensitive behavior riding on a larger differential voltage. For example, a 0 V to 0.6 V step would normally exceed a ±0.5 V input range. By applying 250 mV of offset, the 600 mV step is brought into the dynamic range of the probe and can be viewed accurately. Offset is applied by the probe.

Voltage range

The probe is designed to enable characterization of high frequency circuits with a wide range of differential voltages in the presence of common mode voltages. Understanding the limits and differences between the voltage ratings as discussed in this section is essential to optimize signal fidelity and measurement accuracy.

Although the common mode voltage range of the probe is very large (1000 V CATII), the differential input range is limited and depends on the tip attenuation, the gain range selected, and the applied offset.

The input voltage conditions are divided into several different input ranges.

Common mode voltage range

The probe head is isolated from earth ground, making the common mode input range 1000 V CATII. The differential input range is more limited and refers to the signal that can be applied across the probe tip, regardless of the common mode voltage.

Differential voltage range refers to the actual measurement that will appear on the oscilloscope screen when using IsoVu™. For accurate results, the measurement must fall within the range of any applied offset ±Vdiff range of the tip.Vmeas=Voffset±Vdiff

Offset voltage range

Offset voltage can be applied through the oscilloscope Vertical menu settings. The input offset capability of the probe extends from ±0.5 V to ±50 V depending on the tip used. This offset is applied at the probe head and can be useful to bring applied signals within the dynamic range (Vdiff) of the probe.

Maximum non-destruct differential voltage range

The maximum non-destruct differential input range is the maximum differential voltage that can be applied to the input without damaging the probe. This is a DC +peak AC rating (no portion of the differential input signal should exceed this value). The maximum non-destruct differential voltage varies from ±3 V to ±60 V depending of the probe tip being used. Exceeding these levels will cause permanent damage to components of the probe head.

Specifications

This chapter contains specifications for the instrument. All specifications are typical unless noted as guaranteed. Typical specifications are provided for your convenience but are not guaranteed. Specifications that are marked with the ✔ symbol are guaranteed and checked in Performance Verification.

All specifications are typical and apply to all models unless noted otherwise.

- The instrument must be operating within the environmental limits described in this manual.

- The instrument must have been operating continuously for at least five minutes within the specified operating temperature range.

- The measurement system is powered from a TekVPI compatible oscilloscope.

Warranted specifications describe guaranteed performance with tolerance limits or certain type-tested requirements.

Probe and tip overview

| Probes | TICP100 | TICP050 | TICP025 |

|---|---|---|---|

| Bandwidth | 1 GHz | 500 MHz | 250 MHz |

| Rise time | 400 ps | 700 ps | 1.4 ns |

| DC gain accuracy | ±1.5% | ||

| Maximum common mode voltage | 1800 V; For use in a Pollution Degree 1 environment; Max with transient level not to exceed 5kVpk | ||

| 1300 V; Pollution degree 2; Max with transient level not to exceed 5kVpk | |||

| 600 V for CAT III; Pollution degree 2 | |||

| 1000 V for CAT II; Pollution degree 2 | |||

| RMS noise spectral density | 4.70 nV / √Hz (<21 μVRMS at 20 MHz) | ||

| Probe cable length | 2 meters (78 inches) | ||

Input voltage range, input impedance

Differential input voltage range + offset range will not exceed maximum measurable input voltage. For example, offset limited to ±0.15 V in TICPSMA's ±0.5 V range. Full ±0.5 V offset available in the TICP Series probe's ±0.125 V range.

| Probe tips | Differential input voltage range | Offset range | Maximum measurable input voltage (Vpk) | Maximum non-destructive differential voltage | Input impedance |

|---|---|---|---|---|---|

| TICPSMA | ±0.5 V | ±0.5 V | 0.65 V | ±3 V; 3 VRMS | 50 Ω || N.A. |

| TICPMM1 | ±0.5 V | ±0.5 V | 0.65 V | ±3 V; 3 VRMS | 50 Ω || N.A. |

| TICPMM10 | ±5 V | ±5 V | 6.5 V | ±15 V; 15 VRMS | 500 Ω || <3 pF |

| TICPMM100 | ±50 V | ±50 V | 50 V | ±60 V; 60 VRMS | 5000 Ω || <3 pF |

Noise floor (A RMS)

| Shunt selection | 20 MHz | 250 MHz | 1 GHz |

|---|---|---|---|

| 50 Ω TICP as shunt | 420 nA | 1.5 μA | 3.0 μA |

| 5 Ω shunt | 4.2 μA | 14.9 μA | 29.7 μA |

| 1 Ω shunt | 21 μA | 74.3 μA | 149 μA |

| 500 mΩ shunt | 42 μA | 149 μA | 297 μA |

| 50 mΩ shunt | 420 μA | 1.5 mA | 3.0 mA |

| 5 mΩ shunt | 4.2 mA | 14.9 mA | 29.7 mA |

| 500 μΩ shunt | 42 mA | 149 mA | 297 mA |

| 50 μΩ shunt | 420 mA | 1.5 A | 3.0 A |

| 15 μΩ shunt | 1.4 A | 5.0 A | 9.9 A |

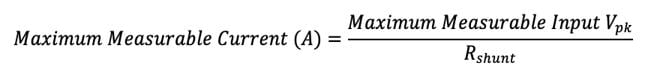

Maximum measurable current

| Shunt selection | TICPMM1 | TICPSMA | TICPMM10 | TICPMM100 |

|---|---|---|---|---|

| 50 Ω TICP as shunt | 13 mA | - | - | |

| 5 Ω shunt | 130 mA | 1.3 A | 10 A | |

| 1 Ω shunt | 650 mA | 6.5 A | 50 A | |

| 500 mΩ shunt | 1.3 A | 13 A | 100 A | |

| 50 mΩ shunt | 13 A | 130 A | 1.0 kA | |

| 5 mΩ shunt | 130 A | 1.3 kA | 10 kA | |

| 500 μΩ shunt | 1.3 kA | 13 kA | 100 kA | |

| 50 μΩ shunt | 13 kA | 130 kA | 1000 kA | |

| 15 μΩ shunt | 43.3 kA | 433.3 kA | 3300 kA | |

Probe Ranges

Numbers are published for TICPSMA and TICPMM1 tips. For 10X or 100X tips, multiply by 10 or 100 respectively.

| Input range | Offset range | RMS noise spectral density (VRMS) | Noise floor at 20 MHz (VRMS) |

|---|---|---|---|

| ±0.5 V | ±0.15 V | 22.9 nV / √Hz | 102.5 µVRMS |

| ±0.35 V | ±0.30 V | 17.4 nV / √Hz | 77.8 µVRMS |

| ±0.25 V | ±0.40 V | 15.0 nV / √Hz | 67.2 µVRMS |

| ±0.175 V | ±0.475 V | 9.5 nV / √Hz | 42.4 µVRMS |

| ±0.125 V | ±0.5 V | 8.7 nV / √Hz | 38.9 µVRMS |

| ±0.09 V | ±0.5 V | 6.3 nV / √Hz | 28.3 µVRMS |

| ±0.065 V | ±0.5 V | 5.5 nV / √Hz | 24.7 µVRMS |

| ±0.045 V | ±0.5 V | 4.7 nV / √Hz | 21.2 µVRMS |

| ±0.03 V | ±0.5 V | 4.7 nV / √Hz | 21.2 µVRMS |

| ±0.02 V | ±0.5 V | 4.7 nV / √Hz | 21.2 µVRMS |

Common mode rejection ratio (CMRR)

| Probe tip | DC | 1 MHz | 100 MHz | 250 MHz | 500 MHz | 1 GHz |

|---|---|---|---|---|---|---|

| TICPSMA | 195 dB | 90 dB | 75 dB | 50 dB | 45 dB | 35 dB |

| TICPMM1 | 140 dB | 90 dB | 80 dB | 70 dB | 70 dB | 50 dB |

| TICPMM10 | 160 dB | 70 dB | 60 dB | 60 dB | 40 dB | 20 dB |

| TICPMM100 | 145 dB | 50 dB | 45 dB | 30 dB | 20 dB | 6 dB |

Application Examples

Application examples for Wide Bandgap (WBG) and PMIC power integrity.

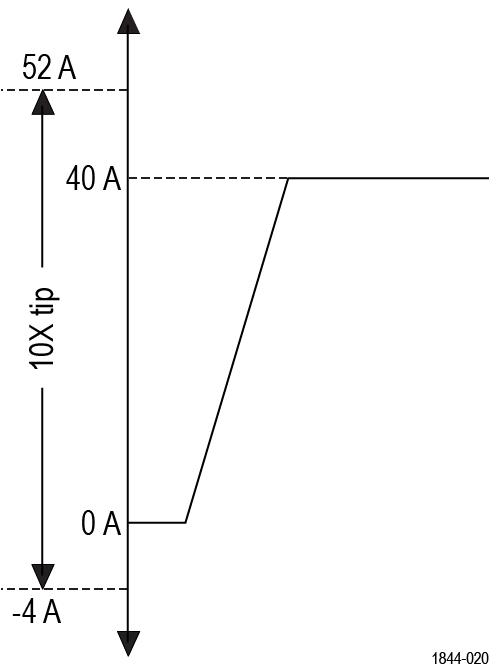

WBG example (800V, 40 A typical; 0.125 Ω shunt)

In a 800 V SiC circuit switching at 40 A, a 125 mΩ shunt will produce a 5 V signal. To measure this using the TICP the 10X tip must be used. In the ±3.5 V range apply 0.3 V of offset.

The measurable current range goes from 52 A to -4 A. At these settings, the RMS noise floor at 250 MHz bandwidth is 2.2 mA RMS

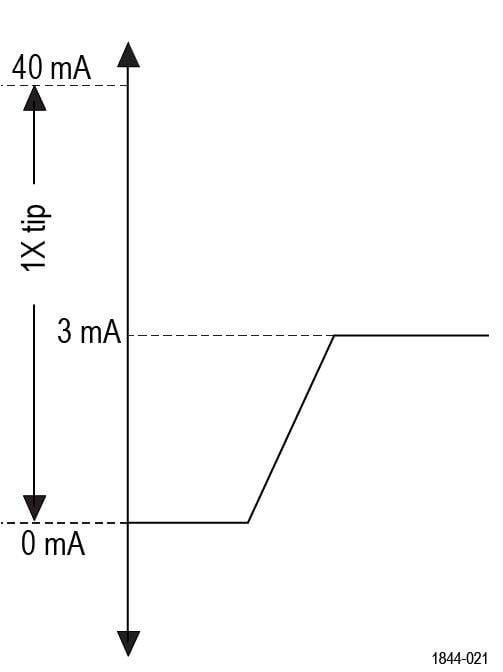

PMIC power integrity (48 V, 3 mA typical; 1 Ω shunt)

On a 48 V PMIC bus, the standby current of 3 mA will produce a 3 mV signal on a 1 Ω shunt. Use the 1X tip in the most sensitive ±20 mV range, apply offset to view the 3mA current and capture transients from 0 A to 40 mA with a RMS noise floor of 21.2 µA

Electrical specifications

- Analog bandwidth

-

Probe tip Bandwidth TICPSMA >1 GHz TICPMM1 >1 GHz TICMM10 >1 GHz TICPMM100 >1 GHz - Linearity

- Deviation of from best line is < ±2% of peak FS

- Input impedance

-

Probe tip Input resistance Input capacitance TICPMM1 50 ±0.5%, 49.75 to 50.25 TICMM10 500 ±2%, 490 to 510 <3 pF TICPMM100 5000 ±2%, 4900 to 5100 <3 pF - Isolated guard line impedance (to earth ground)

- >120 MΩ, ~17 pF

- Offset gain accuracy

- ±0.5%

- Offset linearity

- ±0.1%

- Operating voltage input range

- ±0.65 V maximum differential

- Input coupling

- DC

- DC balance

- < 0.1 divs

- Operating random vibration

- 0.31 GRMS, 5‑500 Hz, 10 minutes per axis, 3 axes (30 minutes total)

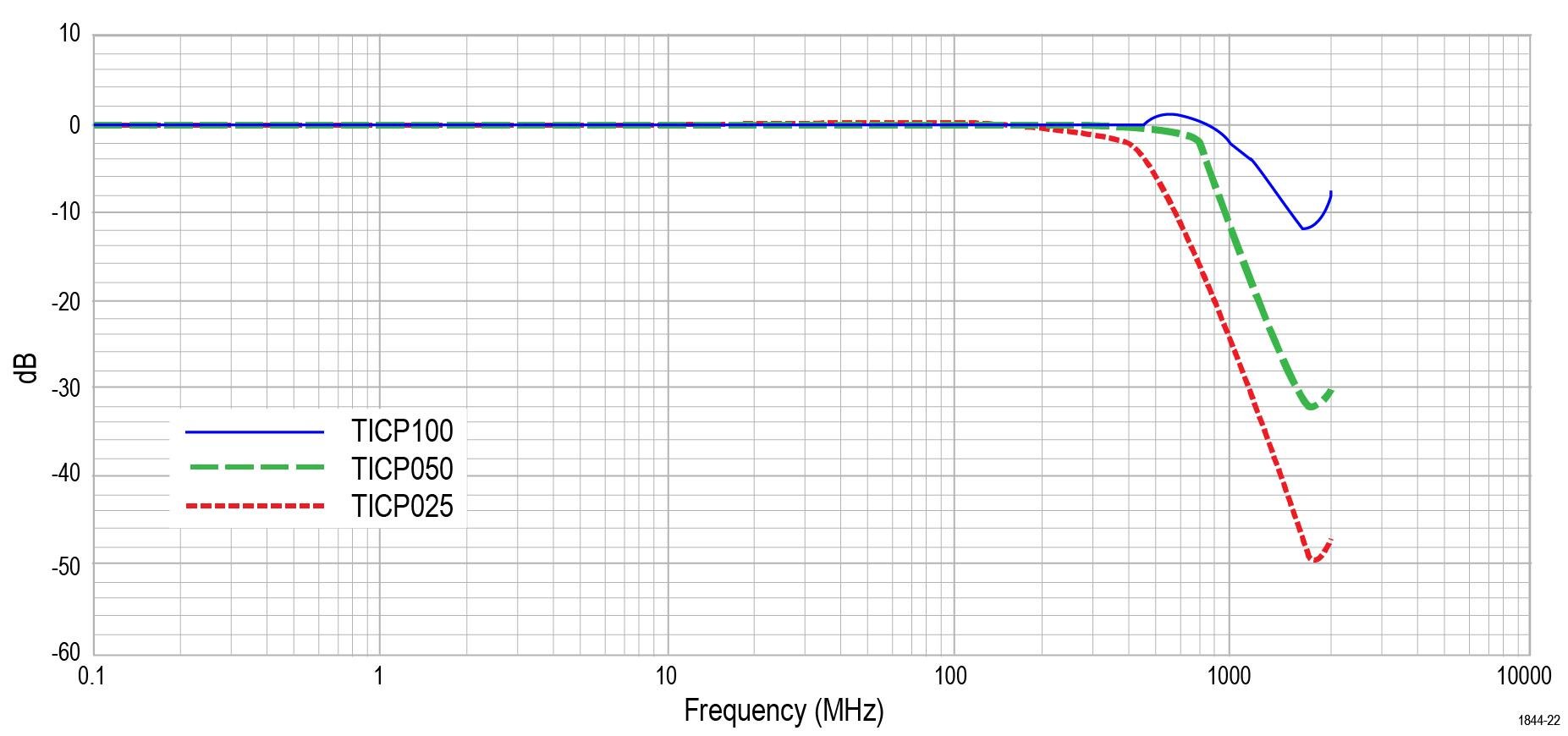

Frequency response graph

The following graph shows the frequency response for each probe.

Regulatory compliance

- EMC

- Conforms to European Union EMC Directive (CE-marked)

- Safety

- Conforms to European Union Low Voltage Directive (CE-marked)

- RoHS

- Conforms to European Union Restrictions on Hazardous Substances (CE-marked)

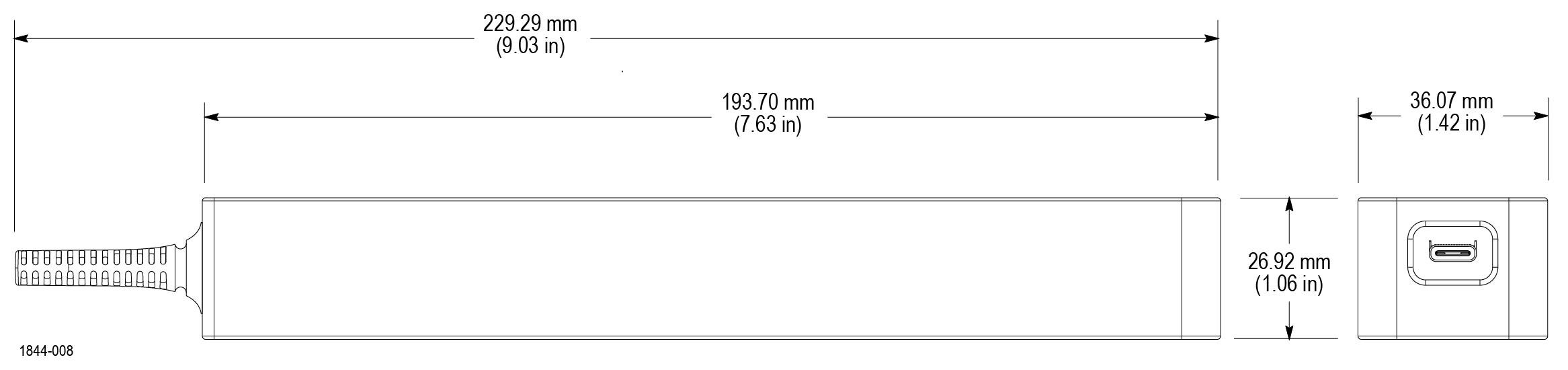

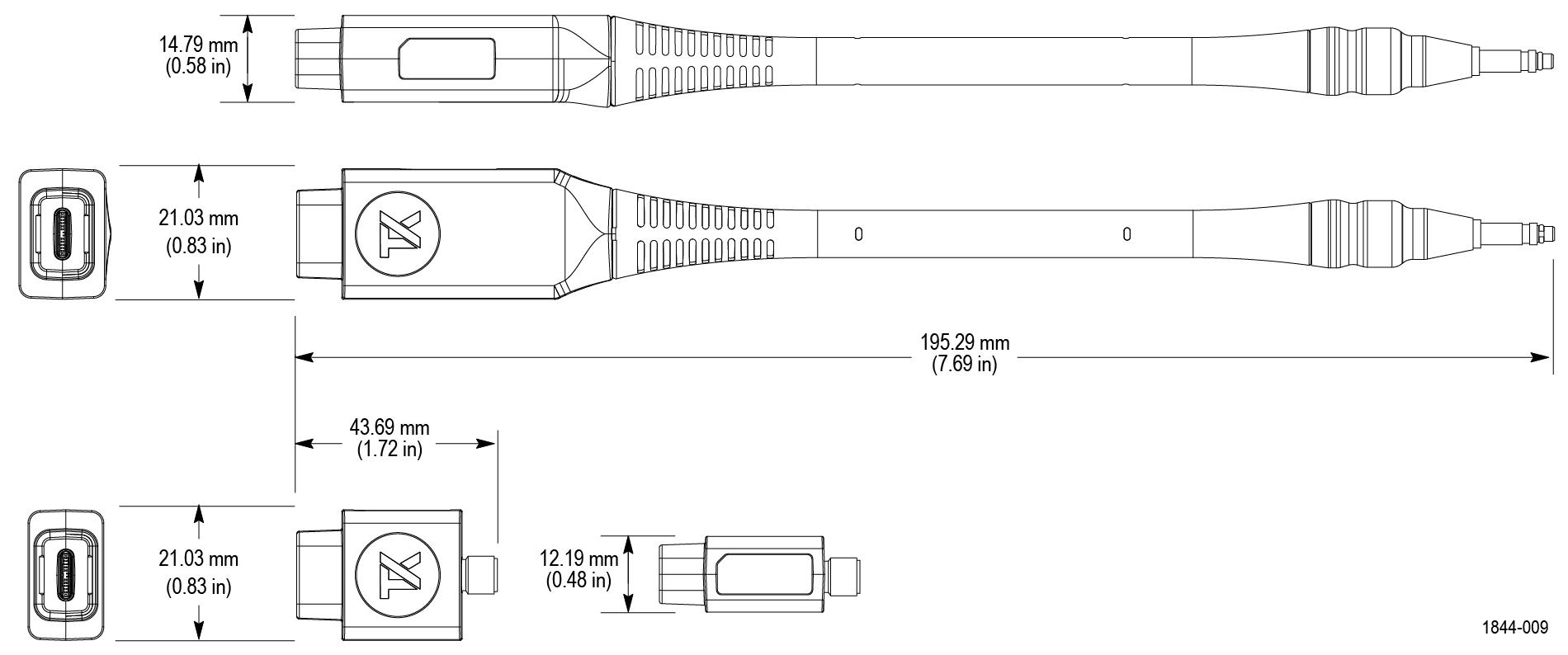

Probe dimensions

Performance verification procedures

Use the following procedures to verify the performance of the IsoVu measurement system. Before beginning the procedures, photocopy the test record and use it to record the performance results. Test record

Required equipment

The equipment required to perform the performance verification procedures are shown in the following table.

| Description | Minimum requirements | Example product |

|---|---|---|

| Supported oscilloscope with TekVPI interface | 50 Ω input support, fully compatible with TekVPI interface | Tektronix 5 Series B MSO |

| DC voltage source | 3 mV to 4 V, ±0.1% accuracy | Fluke 9500B Oscilloscope Calibrator with a Fluke 9500 Active Head |

| SMA male short circuit connector cap (optional) | Internally shorted, copper plated contact | Fairview Microwave SC2135 |

| Digital multimeter (DMM) | 0.1% accuracy or better | Tektronix DMM6500 |

| One 50 Ω terminator | Impedance 50 Ω; connectors: female BNC input, male BNC output | Tektronix part number 011-0049-XX |

| Precision termination test fixture | Tektronix part number 067-3281-XX | |

| TekVPI calibration performance verification fixture | Tektronix part number 067-1701-XX |

System RMS Noise

This procedure verifies that the TICP Series probes are functioning and meet the warranted noise specification. The noise will be measured with no input signal at the most sensitive range.

Before you begin

- Turn on the TekVPI oscilloscope.

- Connect the TICP probe to the oscilloscope on channel 1 and remove the TICP probe tip (if attached).

- Allow the test equipment to warm up for 30 minutes at an ambient temperature of about 20 °C (68 °F).

About this task

This procedure is valid for all versions of the TICP Series probe.

Procedure

- Tap File > Default Setup.

- Run Signal Path Compensation, if recommended in Utility > Calibration...

- Run self-calibration (Self-calibration).

- Connect the TICPSMA probe tip to TICP probe.

- Connect the SMA short connector cap to TICPSMA.

- Enable the TICP channel and use the following Vertical menu settings:

- Vertical Scale: 1 mV/div

- Edit Trigger menu settings as follows:

- Type: Edge

- Source: AC Line

- Slope: Rising

- Level: 0 V

- Coupling: DC

- Edit Horizontal menu settings as follows:

- Horizontal Scale: 100 µs/div

- Record Length: 6.25 M

- Edit the following Acquisition menu setting:

- Single Sequence Stop After: 1 Acquisitions

- Add a measurement with the following settings:

- Amplitude Measurement: AC RMS

- Source: CH 1

- Press the Single / Seq button to perform the measurement.

- Record the AC RMS measurement result in the test record table.

System RMS noise test record

Use the test record table for recording the results of the system RMS noise performance verification procedure.

|

Model number:

Serial number:

|

Procedure performed by:

Date:

|

| Probe | Maximum noise | Measured noise |

|---|---|---|

| TICP025 | 75 µVrms |

|

| TICP050 | 125 µVrms |

|

| TICP100 | 155 µVrms |

|

DC Gain Accuracy

This procedure verifies that the TICP Series probes are functioning and meet the warranted DC gain accuracy.

Before you begin

- Turn on the TekVPI oscilloscope.

- Connect a 067-3281-XX 50 Ω precision termination to the output of the 067-1701-XX fixture.

- Connect a DMM to the 50 Ω precision output with a BNC tee.

- Connect a BNC cable from the tee at the output of the 50 Ω precision termination to any other oscilloscope channel. Verify the channel is in 1 MΩ mode and 200 mV/div. This is used for proper grounding only.

- Connect the 067-1701-XX fixture into channel 1 on the oscilloscope.

- Connect the TICP Series probe into the 067-1701-XX fixture.

- Turn on the Fluke 9500B Oscilloscope Calibrator.

- Connect the Fluke 9530 Active Head to the Fluke 9500B on channel 1.

- Allow the test equipment to warm up for 30 minutes at an ambient temperature of about 20 °C (68 °F).

About this task

This procedure is valid for all versions of the TICP Series probe.

Procedure

- Tap File > Default Setup.

- Run Signal Path Compensation, if recommended in Utility > Calibration...

- Run self-calibration (Self-calibration).

- Connect the TICPSMA probe tip to TICP probe.

- Connect the TICPSMA to the Fluke 9500 Active Head.

- Enable the TICP channel and use the following Vertical menu settings:

- Range Mode: Manual

- Range: 500 mV

- Offset: 0 V

- On the Fluke 9500B, select Mode: Manual Waveform with the following settings:

- Select Waveform: DC

- Select 400 mV/div

- Turn output ON

- Press the Single / Seq button to perform the measurement.

- Record the DC voltage on the precision 50 Ω resistor in the table.

- Press invert voltage (+/-) button on the Fluke 9500B to apply -400 mV to the probe and record the output voltage in the table.

- Repeat the entire procedure for the remaining ranges and record the values in the test record table.

DC Gain Accuracy test record

Use the test record table for recording the results of the DC gain accuracy performance verification procedure.

|

Model number:

Serial number:

|

Procedure performed by:

Date:

|

Probe gain is defined as the change in Output divided by the change in input.

Gain=(Measurement1-Measurement2)/(Input1-Input2)

| Range | Input 1 | Input 2 | Measured output 1 | Measured output 2 | Calculated gain | Upper gain limit | Ideal gain | Lower gain limit |

|---|---|---|---|---|---|---|---|---|

| 500 m | +0.400 V | -0.400 V |

|

|

| 1.010 | 1.000 | 0.990 |

| 350 m | +0.280 V | -0.280 V |

|

|

| 1.443 | 1.429 | 1.415 |

| 250 m | +0.200 V | -0.200 V |

|

|

| 2.020 | 2.000 | 1.980 |

| 175 m | +0.140 V | -0.140 V |

|

|

| 2.886 | 2.857 | 2.828 |

| 125 m | +0.100 V | -0.100 V |

|

|

| 4.040 | 4.000 | 3.960 |

| 90 m | +0.072 V | -0.072 V |

|

|

| 5.612 | 5.556 | 5.500 |

| 65 m | +0.052 V | -0.052 V |

|

|

| 7.769 | 7.692 | 7.615 |

| 45 m | +0.036 V | -0.036 V |

|

|

| 11.222 | 11.111 | 11.000 |

| 30 m | +0.024 V | -0.024 V |

|

|

| 16.834 | 16.667 | 16.500 |

| 20 m | +0.016 V | -0.016 V |

|

|

| 25.250 | 25.000 | 24.750 |

DC Balance

This procedure verifies that the TICP Series probes are functioning and meet the warranted residual offset when input is zero and offset is zero.

Before you begin

- Turn on the TekVPI oscilloscope.

- Connect a 067-3281-XX 50 Ω precision termination to the output of the 067-1701-XX fixture.

- Connect a DMM to the 50 Ω precision output with a BNC tee.

- Connect a BNC cable from the tee at the output of the 50 Ω precision termination to any other oscilloscope channel. Verify the channel is in 1 MΩ mode and 200 mV/div. This is used for proper grounding only.

- Connect the 067-1701-XX fixture into channel 1 on the oscilloscope.

- Connect the TICP Series probe into the 067-1701-XX fixture.

- Allow the test equipment to warm up for 30 minutes at an ambient temperature of about 20 °C (68 °F).

About this task

This procedure is valid for all versions of the TICP Series probe.

Procedure

- Tap File > Default Setup.

- Run Signal Path Compensation, if recommended in Utility > Calibration...

- Run self-calibration (Self-calibration).

- Attach the TICPSMA probe tip to TICP probe.

- Enable the TICP channel and use the following Vertical menu setting:

- Range mode: Manual

- Probe range: 500 mV

- Press the Single / Seq button to perform the measurement.

- Measure the voltage on the output side of the precision 50 Ω termination with the DMM.

- Repeat the entire procedure for the remaining ranges and record the values in the test record table.

DC Balance test record

Use the test record table for recording the results of the DC balance performance verification procedure.

|

Model number:

Serial number:

|

Procedure performed by:

Date:

|

The residual output for any range should be less than ±10 mV.

| Range | Limit | Measured |

|---|---|---|

| 500 mV | ±10 mV |

|

| 350 mV | ±10 mV |

|

| 250 mV | ±10 mV |

|

| 175 mV | ±10 mV |

|

| 125 mV | ±10 mV |

|

| 90 mV | ±10 mV |

|

| 65 mV | ±10 mV |

|

| 45 mV | ±10 mV |

|

| 30 mV | ±10 mV |

|

| 20 mV | ±10 mV |

|

Offset Gain Accuracy

This procedure verifies that the TICP Series probes are functioning and meet the warranted offset gain accuracy.

Before you begin

- Turn on the TekVPI oscilloscope.

- Connect a 067-3281-XX 50 Ω precision termination to the output of the 067-1701-XX fixture.

- Connect a DMM to the 50 Ω precision output with a BNC tee.

- Connect a BNC cable from the tee at the output of the 50 Ω precision termination to any other oscilloscope channel. Verify the channel is in 1 MΩ mode and 200 mV/div. This is used for proper grounding only.

- Connect the 067-1701-XX fixture into channel 1 on the oscilloscope.

- Connect the TICP Series probe into the 067-1701-XX fixture.

- Allow the test equipment to warm up for 30 minutes at an ambient temperature of about 20 °C (68 °F).

About this task

This procedure is valid for all versions of the TICP Series probe.

Procedure

- Tap File > Default Setup.

- Run Signal Path Compensation, if recommended in Utility > Calibration...

- Run self-calibration (Self-calibration).

- Attach the TICPSMA probe tip to TICP probe.

- Attach the TICPSMA to the Fluke 9500 Active Head.

- Enable the TICP channel and use the following Vertical menu settings:

- Range: 20 mV

- Offset: 20 mV/div

- On the Fluke 9500B, select Mode: Manual Waveform with the following settings:

- Select Waveform: DC

- Select 20 mV/div

- Turn output ON

- Press the Single / Seq button to perform the measurement.

- Add the offset with value measured on the DMM.

- Repeat the entire procedure with all of the following oscilloscope offset and Fluke input voltage settings: 0.25 V, 0 V, -0.25 V, and -0.5 V.

Offset Gain Accuracy test record

Use the test record table for recording the results of the offset gain accuracy performance verification procedure.

|

Model number:

Serial number:

|

Procedure performed by:

Date:

|

- Input the offset voltages and corresponding measured mean result into Excel.

- Create a scatter plot of the data with offset voltages in the Y-axis and mean voltages in the X-axis.

- Add a trend line to the plot and select to show the equation .

The best fit of the data should have a slope between 0.995 and 1.005 to meet a 1% accuracy.

| Range | 500 mV measurement | 250 mV measurement | 0 V measurement | -250 mV measurement | -500 mV measurement | Limits | Calculated |

|---|---|---|---|---|---|---|---|

| 20 mV |

|

|

|

|

| 0.995 < x < 1.005 |

|

Maintenance

Information to isolate possible failures and procedures for maintaining your probe.

Service offerings

Tektronix provides service to cover repair under warranty and other services that are designed to meet your specific service needs.

Tektronix service technicians are well equipped to service your probe. Services are provided at Tektronix Service Centers and on-site at your facility, depending on your location. Visit tek.com/service to view all available services. Check the status of your warranty at tek.com/warranty-status-search.

Cleaning

| CAUTION:To prevent damage to the measurement system, do not expose it to sprays, liquids, or solvents. Avoid getting moisture inside the comp box or sensor head when cleaning the exterior. |

Clean the exterior surfaces with a dry, lint-free cloth or a soft-bristle brush. If dirt remains, use a soft cloth or swab dampened with a 75% isopropyl alcohol solution. Use only enough solution to dampen the cloth or swab. Do not use abrasive compounds on any part of the instrument.

Maintain the integrity of the connectors by keeping them free of contamination. Remove any debris from the connectors using low-pressure, clean, dry, compressed air.

Troubleshooting and error conditions

The following describes the state of each LED and possible problems that you might encounter when taking measurements with the probe. Use this as a quick troubleshooting reference before contacting Tektronix for service.

| LED | Status | Action | |

|---|---|---|---|

| Green (Solid) | Normal operation | - |

| Green (Blinking) | Bulk power failure | Try unplugging and plugging back in. Inspect probe/oscilloscope interface. Service of probe may be required. |

| Red (Solid) | Probe application failure | Try unplugging and plugging back in. Service of probe may be required. |

| Red (Blinking) | Probe application failure and bulk power failure | Try unplugging and plugging back in. Inspect probe/oscilloscope interface. Service of probe and/or oscilloscope may be required. |

| Red (Blinking • • – ) | No power to the isolated side of the probe | Try unplugging and plugging back in. Service of probe may be required. |

| Problem | Solution | ||

|---|---|---|---|

| DC offset is present in signal |

| ||

| The Square Wave edge appears “smoothed”, rolled off, or uncompensated |

| ||

| The measured amplitude is smaller than expected |

| ||

| DC measurement inaccuracy |

| ||

| There is too much noise and you cannot accurately measure small signals |

| ||

| There is no signal detected; the waveform is a flat line |

| ||

| The probe head loses power intermittently |

| ||

| There is too much common mode noise |

| ||

| No tip detected warning |

| ||

Repack the measurement system for shipment

If you need to return the measurement system to Tektronix for repair, use the original packaging. If this is unavailable or not fit for use, contact your Tektronix representative to obtain new packaging.

When you return the measurement system to Tektronix, attach a tag showing the following information:

-

Name of the product owner

-

Address of the owner

-

Instrument serial number

-

A description of problems encountered and/or service required

Remote programming

This sections describes commands and queries that can be sent to the sensor head when attached to a Tektronix oscilloscope. Long-form and short-form keywords are indicated with upper/lower case letters. The commands and queries are supported by most oscilloscopes; differences in supporting oscilloscopes, if any, are described with the commands.

For additional information, refer to the programmer documentation for your oscilloscope.

Command list

The commands and queries are supported by most oscilloscopes; differences in supporting oscilloscopes, if any, are described with the commands. For additional information, refer to the programmer documentation for your oscilloscope.

CH<x>:PRObe? (Query Only)

This query-only command returns all information concerning the probe that is attached to the specified channel. The channel is specified by x.

- Syntax

CH<x>:PRObe?- Examples

CH2:PROBE?might return1.0000E-01; RESISTANCE 1.0000E+07;UNITS "V";ID:TYPE "10X"'SERNUMBER "N/A"for a 10X probe, indicating that (among other parameters) the attenuation factor for the probe attached to Channel 2 is 100.0 mV (assuming that probe units are set to volts).

CH<x>:PRObe:AUTOZero (No Query Form)

This command executes the AutoZero function. The operation is entirely performed by the oscilloscope. The channel is specified by x.

Refer to the self-calibration procedure for information on performing the self calibration. Self-calibration

- Syntax

CH<x>:PRObe:AUTOZero EXECute- Arguments

EXECutesets the probe attached to the specified channel to AutoZero.- Examples

CH1:PROBE:AUTOZERO EXECUTEsets the probe attached to the Channel 1 to autozero.

CH<x>:PRObe:FORCEDRange

The command selects the dynamic range of probe (1 of 9) in +/-V. It is dependent on the attached probe tip. The channel is specified by x. The command should only be used when CH<x>:PROBECONTROL is set to MANUAL.

| Probe tip cable | Dynamic Range +/-V |

|---|---|

| No tip or 1X tip | 0.02 | 0.03 | 0.045 | 0.065 | 0.09 | 0.125 | 0.175 | 0.25 | 0.35 | 0.5 |

| 10X | 0.2 | 0.3 | 0.45 | 0.65 | 0.9 | 1.25 | 1.75 | 2.5 | 3.5 | 5.0 |

| 100X | 2 | 3 | 4.5 | 6.5 | 9 | 12.5 | 17.5 | 25 | 35 | 50 |

The query returns the dynamic range of the probe tip in +/-V.

- Syntax

CH2:PRObe:FORCEDRange <NR3>- Arguments

<NR3>specifies the probe dynamic range- Examples

-

If a current probe is attached to the Channel 1 input,

CH1:PROBE:FORCEDRANGE 5.0sets the attached probe to its 5 V range.CH3:PROBE:FORCEDRANGE?might return5.0000, indicating that the range of the probe attached to the Channel 3 is set to 5 V.

CH<x>:PRObe:GAIN? (Query Only)

The command returns the gain factor of the currently selected range (inverse of attenuation). The channel is specified by x.

- Syntax

CH<x>:PRObe:GAIN?- Examples

CH2:PROBE:GAIN?might return100.0000E-3, indicating that the attached 10X probe delivers 0.1 V to the Channel 2 BNC for every 1.0 V applied to the probe input.

CH<x>:PRObe:ID? (Query Only)

This query-only command returns the type and serial number of the probe that is attached to the specified channel. The channel is specified by x.

- Syntax

CH<x>:PRObe:ID?- Examples

CH2:PROBE:ID?might return"B010289";"TICP100", indicating that a TICP100 probe with serial number B010289 is attached to Channel 2.

CH<x>:PRObe:ID:SERnumber? (Query Only)

This query-only command returns the serial number of the probe that is attached to the specified channel. The channel is specified by x.

| Note:For Level 0 and 1 probes, the serial number will be “N/A”. |

- Syntax

CH<x>:PRObe:ID:SERnumber?- Examples

CH1:PROBE:ID:SERNUMBER?might return"B010289", indicating that the serial number of the probe attached to Channel 1 is B010289.

CH<x>:PRObe:ID:TYPe? (Query Only)

This query-only command returns the type of probe that is attached to the specified channel. The channel is specified by x.

- Syntax

CH<x>:PRObe:ID:TYPe?- Examples

CH1:PROBE:ID:TYPE?might return"TICP100", indicating that a TICP100 probe is attached to Channel 1.

CH<x>:PRObe:SELFCal:State? (Query Only)

This query-only command returns the self-calibration state of RECOMMENDED, RUNNING, or PASSED. The channel is specified by x.

- Syntax

CH<x>:PRObe:SELFCal:State?- Examples

CH1:PRObe:SELFCal:State?might returnRUNNING, indicating that the Channel 1 probe is currently running a self-calibration.

CH<x>:PRObe:SELFCal

This query-only command initiates self-calibration on the probe. The channel is specified by x.

- Syntax

CH<x>:PRObe:SELFCal EXECUTE- Examples

CH1:PRObe:SELFCal EXECUTEruns self-calibration on the Channel 1 probe.

CH<x>:PRObe:STATus? (Query Only)

This command queries the probe unsigned integer error value. The channel is specified by x.

- Conditions

- Requires a probe that supports the relevant error messages.

- Syntax

CH<x>:PRObe:STATus?- Returns

- Returns an integer number that represents the sum total of binary error bits B0 – B15. The error bits are not displayed; they are concatenated into the integer value. The following is a list of the error for each bit.

- B0 – Probe disabled

- B1 – Jaws open

- B2 – Over range

- B3 – Probe temperature out of limits

- B4 – Degauss needed

- B5 – Probe tip missing

- B6 – Probe tip failed

- B7 – Probe tip not supported

- B8 – self-calibration is needed or recommended (the query will return 256 in decimal format)

- B9 through B15 – Reserved

- Examples

CH4:PROBE:STATus?might return2, indicating that the probe is reporting an open jaws error.

CH<x>:PRObe:UNIts? (Query Only)

This query-only command returns a string describing the units of measure for the probe attached to the specified channel. The channel is specified by x.

- Syntax

CH<x>:PRObe:UNIts?- Examples

CH4:PROBE:UNITS?might return"V", indicating that the unit of measure for the probe attached to Channel 4 is Volts.

CH<x>:PROBECOntrol

This command sets or queries multirange probe range-control policy preference of the probe that is attached to CH<x>. The channel number is specified by x.

- Syntax

CH<x>:PROBECOntrol {AUTO|MANual}- Arguments

AUTOsets the values. The probe range is automatically calculated.- Examples

-

CH2:PROBECONTROL AUTOsets the values and the probe range is automatically calculated.

CH<x>:PROBEFunc:EXTAtten

This command is used to specify the attenuation value as a multiplier to the given scale factor on the specified channel. The channel is specified by x.

The query form of this command returns the user-specified attenuation.

- Syntax

CH<x>:PROBEFunc:EXTAtten <NR3>- Arguments

<NR3>is the attenuation value, which is specified as a multiplier in the range from 1.00E-10 to 1.00E+10.- Examples

CH1:PROBEFUNC:EXTATTEN 167.00E-3specifies an external attenuation, which is connected between the your input signal and the input of the probe attached to Channel 1.

CH<x>:PROBEFunc:EXTDBatten

This command sets or queries the input-output ratio (expressed in decibel units) of external attenuation or gain between the signal and the instrument input channels. The channel is specified by x.

The query form of this command returns the user-specified attenuation in decibels.

- Syntax

CH<x>:PROBEFunc:EXTDBatten <NR3>- Arguments

<NR3>is the attenuation value, which is specified in the range from -200.00 dB to 200.00 dB.- Examples

CH3:PROBEFUNC:EXTDBATTEN 2.5specifies an external 2.5 dB attenuator on Channel 3.

CH<x>:PROBEFunc:EXTUnits

This command sets the unit of measurement for the external attenuator of the specified channel. The channel is specified by x. The alternate units are used if they are enabled. Use the CH<x>:PROBEFunc:EXTUnits:STATE command to enable or disable the alternate units.

- Syntax

CH<x>:PROBEFunc:EXTUnits <QString>- Arguments

<QString>indicates the attenuation unit of measurement for the specified channel.- Examples

CH4:PROBEFUNC:EXTUNITS "Pascals"sets the unit of measurement for the Channel 4 external attenuator.

CH<x>:PROBEFunc:EXTUnits:STATE

This command sets or queries the custom units enable state for the specified channel. The channel is specified by x.

- Syntax

CH<x>:PROBEFunc:EXTUnits:STATE {ON|OFF|<NR1>}- Arguments

OFFargument turns off external units.- Examples

CH2:PROBEFunc:EXTUnits:STATE ONturns on external units.

CH<x>:PROBE:DYNAMICRANGE? (Query Only)

This command queries the dynamic range of the probe that is attached to the specified channel. The channel is specified by x.

- Syntax

CH<x>:PROBE:DYNAMICRANGE?- Returns

- The returned value is the delta between the current minimum and maximum range with some tolerance. It is also the delta between the probe range indicators (if currently displayed).

- Examples

CH1:PROBE:DYNAMICRANGE?might return1.3056, indicating that the dynamic range of the probe attached to the Channel 1 is set to 1.3056 V.

Help us improve our technical documentation. Provide feedback on our TekTalk documentation forum.